- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bottle filling machine

Results for

Bottle filling machine - Import export

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Longtime Blanc. Molub-Alloy Blanc (05/20/2021) White multi-purpose grease for high bearing pressures and long-term lubrication Description Castrol Molub-Alloy Blanc (previous product name Castrol Longtime Blanc) is a white multi-purpose grease for use at high bearing pressures and long-term lubrication. It is characterized by its special adhesive properties and its water-resistant, sealing properties. Application Molub-Alloy Blanc is used in the food and beverage industry, especially in wet operations, in dusty environments and in conveyor lines, canning and bottle filling systems and labeling machines, where there is no contact between the lubricant and the food or beverage . Molub-Alloy Blanc can be used for long-term lubrication under high pressure loads, vibrations, shock loads, in highly loaded joints, plain and rolling bearings and pipe tracks.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Longtime Blanc. Molub-Alloy Blanc White multi-purpose grease for high bearing pressures and long-term lubrication Description Castrol Molub-Alloy Blanc (previous product name Castrol Longtime Blanc) is a white multi-purpose grease for use at high bearing pressures and for long-term lubrication. It is characterized by its special adhesive properties and its water-resistant, sealing behavior. Application Molub-Alloy Blanc is used in the food and beverage industry, especially in wet operations, in dusty environments and in conveyor lines, canning and bottle filling systems and labeling machines, where there is no contact between the lubricant and the food or beverage . Molub-Alloy Blanc can be used for long-term lubrication under high pressure loads, vibrations, shock loads, in highly loaded joints, plain and rolling bearings and pipe tracks.

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Fast filling of multiple containers on a single pallet. Filling station with electronic scale for filling liquids which foam, are gaseous or generate static electricity, e.g. cleaning agents, solvents, chemical liquids, mineral oils, glazes. For the filling of bunghole containers, e.g. canisters, bunghole drums or IBCs directly on the pallet. Below level filling, coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. ■ an almost foam-free, calibratable below level filling of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ rapid changeover to other container sizes and changing products ■ simple operation by one person ■ handling of empty containers (lifting heavy loads (filled containers)) not applicable ■ automatic height adjustment and automatic change of position

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of non-frothing liquids e.g. chemical liquids or oils. For the filling of open bunghole containers, such as canisters, bunghole drums or IBCs (Intermediate Bulk Container), directly on the pallet. Below bunghole filling coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ an almost froth-free, calibratable below bunghole filling of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ rapid changeover to other container sizes and changing products ■ simple operation by one person ■ Handling of empty containers (lifting heavy loads (filled containers)) not applicable

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION compact design. made up to our German technology, to meet all the international and the European standards. One side labeling machine with coding, dating system Our machine can handle a large type of label, Bottles, and caps Types, size and shapes. SPECIFICATION Pneumatic paddle Volumetric filling system Type of metal used S.S 316 Labeling head. Pneumatic capping gun Drawer feeding caps Label coding system Mechanical weight adjustment system Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

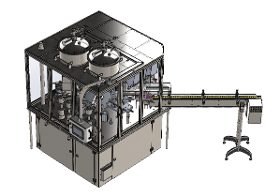

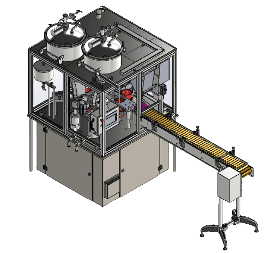

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 2 diving filling nozzles Star capping and closing system Labeling machine 1 head HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION compact design. made up to our German technology, to meet all the international and the European standards. Our machine can handle a large type of vial bottles , types and shapes SPECIFICATION Machine is made up to the international GMP regulations Turn table feeding system Type of metal used S.S 316 Double Sterilizing nozzles system before and after filling. 2 diving filling nozzles 2 Peristaltic pumps Double star filling and capping system Double caps vibrator feeding system 1 Rubber vial stopper mushroom, 2 aluminum flip caps Rotary capping servo system Delaying bottles conveyor system Herma labeling head HMI and SCADA system with interactive touch screen control system Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q , O.Q , P.Q, DQ.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Continuous rotary blowing machine 6 heads diving filling nozzles Star sterilizing capping and closing system Herma Labeling machine 1 heads One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION One bottles feeding turning table One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Star; sterilizer, filling, capping, closing system. 1 head Diving filling nozzles One side labeling machine. 1 peristaltic pump. 2 dropper and caps feeding system.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 2 heads diving filling nozzles Star capping and closing system Herma Labeling machine 1 heads One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer aligner station is a solution if you have to feed glasses, bottles or tins aligned into a filling or labelling machine. By using high-performance product identification up to 350 products/min. can be identified and aligned in a continuous flow of materials. New products can easily be saved with the electrical control system's user-friendly operator interface. Technical data: —Conveyor performance: up to 350 items/min. —Installation length: 1500 mm (identification and alignment) —Infinitely variable adjustment to product height and width Optional equipment: —Camera housing against the influence of other light —High-speed camera for precise alignment even at high conveyor performance —Automatic discharging of faulty products

Request for a quote

OPTIMA PHARMA GMBH

Germany

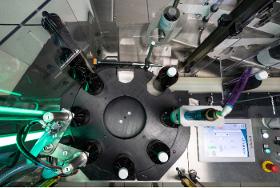

ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) Aseptic fields of application Gently objective handling Disposable product path optional Dosing system: Mass flow with CIP/ SIP optional Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

WHITESTEEL GMBH

Germany

- Compact design - Made up to the ISO, FDA and EU, GMP and cGMP international standards - Can handle multiple cups shapes and sizes - SCADA system included - Touch screen included - Capacity is adjustable up to your needs - Can be used For all liquid substance including alcohol, sanitizers, hand gel, and more

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

An automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five work stages that start with pulling the empty containers, then filling them, then placing the covers, then welding and taking out through the conveyor belt. It is suitable for high and medium production with a productivity of 3000 packages per hour.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

an automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five stages of work, starting with pulling the empty containers, then filling them, then placing the aluminum or nylon cover, then welding with cutting and taking out through the conveyor belt. It is suitable for medium production with a productivity of 1500 packages per hour.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LIQUID-UNIVERSUM GMBH

Germany

filling machines for liquids 550ml and 1001000ml (cbd oil, e liquid, desinfection, cosmetics, nutritions, vitamins)

Request for a quoteResults for

Bottle filling machine - Import exportNumber of results

19 ProductsCountries

Company type

Category

- Bottling and filling - machinery and equipment (10)

- Food industry - machinery and equipment (6)

- Automation - systems and equipment (3)

- Pharmaceutical industry - machinery and equipment (3)

- Lubricants, industrial (2)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Conveyor belts (1)