- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- zinc aluminum

Results for

Zinc aluminum - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the products used in fashion decoration products.The material are aluminum alloy,zinc alloy and brass and so on...

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The double anodization process can be used to create a protective anodization layer on various parts of a consumer electronic product, including top and bottom portions, side walls, and chamfered portions. It’s particularly useful for improving corrosion resistance and wear resistance, and it provides better adhesion for paint primers and glues than bare metal does. The process is not limited to aluminum; it can also be applied to other metals like titanium, zinc, magnesium, and others. However, aluminum is the most common due to its widespread use in consumer electronics and other applications where weight and durability are important factors.Double anodization is a complex process that requires precise control over the electrolytic solutions, electrical current, and time to ensure the desired outcome. It’s a testament to the advancements in materials engineering and its ability to tailor the properties of metals for specific applications.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Metric: Screws from M2 x 10 – M30 x 1000 with thread (up to 100 mm long). Compliant with DIN, EN, ISO, or according to drawings and samples. Plates: From ST 2.9 x 19 – ST 6.3 x 160 / 80 mm with thread (up to 80 mm long). Compliant with DIN, EN, ISO, or according to drawings and samples. KTG screws for plastics: 30-degree thread (OEB Kunst). KTG 3 x 10 mm – KTG 8 x 160 mm with thread (up to 60 mm long). DIN 7500 thread grooving screws: For die casting, zinc or aluminium. M3 x 20 – M10 x 160 mm with thread (up to 50-60 mm long) (OEB Furch). DIN 7513 – DIN 7516 thread cutting screws: For die casting, zinc or aluminium. M3 x 20 – M10 x 160 mm with thread (up to 50-60 mm long) (OEB Schneid). Other thread types: With-Worth, HiLo, UNC/UNF, double-start, triple-start.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Occasionally also these terms are used for cartridge heates: heating cartridge, insertion heaters, spiral cartridge heaters. As a rule cartridge heaters consist of a cylindrical stainless steel tube and thus provide a high corrosion prevention. There is a heating wire inside which is wound onto a ceramic core. The number of coils varies depending on the power. In order to avoid a short-circuit, the cartridge heater is filled with magnesium oxide and compressed afterwards. Highly compacted they reach a surface watt density of up to 50 W/cm² and withstand highest stress. In the plastics industry cartridge heaters are used in hot runners in order to temper thermoplasts during injection moulding processes. Other areas of applications for process heat are e. g. packaging, diecasting or continuous casting in which zinc or aluminium are processed. Further applications are to be found in mechanical as well as medical and laboratory engineering.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Designed to be used as lockable filler ports for hydraulic reservoirs, allowing the reservoir to breathe whilst protecting it from contamination found in harsh environments Types ▪ SMBL-C (Clamping version) ▪ SMBL-P (Screw-in version) ▪ SMBL-P (Push-on version) Features ▪ Available as clamping version (with 3 clamping jaws), as threaded version (with female BSP thread) or push-on version, suitable for stand pipe mounting with pipe diameters up to 77,5 mm / 3.05 in (secured by 3 locking screws) ▪ Key-lockable cap (2 keys included) ▪ Lock protected by rotating flap ▪ Air flow in both directions, one direction only or no direction Materials ▪ Breather cap made of Aluminium, lacquered (light-grey, RAL 9022) ▪ Breather body made of Aluminium, zinc-plated ▪ Basket made of Steel, zinc-plated or Polypropylene (PP) ▪ Sealings made of NBR (Buna-N®) (standard option); FPM (Viton®) sealed version available Technical Data ▪ Operating temperature range: -30 °C ... +100 °C / -22 °F ......

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ABS SAFETY GMBH

Germany

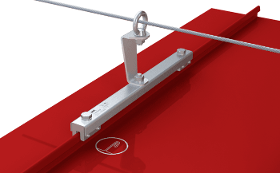

Depending on the subsurface (steel, copper, aluminium or titanium zinc), this stainless steel anchorage point can be installed on a metal roof using either aluminium or brass clamps. It is simply attached to a standing or copper standing seam using the specially-designed clamps supplied - completely penetration-free. EN 795:2012, A + CEN/TS 16415:2013 Freely-rotating anchor eyelet Clamped onto a seam without penetrating your roof surface Mounted on a single seam For steel and stainless steel ≥ 0.5 mm; copper ≥ 0.6 mm; titanium zinc and aluminium ≥ 0.7 mm For Rheinzink and similar systems Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel, type B roof safety hook for metal seam roofs is suitable for all directions of load (apart from axial loads). It is simply clamped onto a seam without needing to penetrate the roof surface. Our roof hook is installed quickly and easily using the 4 nuts and bolts supplied. Roof safety hook in accordance with EN 517:2006, type B Anchorage point for PPE + ladder hooks For stainless steel ≥ 0.5mm; copper and titanium zinc ≥ 0.6mm; aluminium ≥ 0.7mm Simple, penetration-free installation using just 4 bolts Designed for rounded-edge and standing edge roofs Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel intermediate bracket - specially designed for lifeline systems - was developed for penetration-free installation on a standing seam roof. This device is attached using aluminium or brass clamps depending on your subsurface (steel, copper, aluminium or titanium zinc). EN 795:2012, C + CEN/TS 16415:2017 Clamped onto a standing seam without penetrating your roof surface Mounted on a single seam For Rheinzink and similar systems; also suitable for copper standing seam panels (Cu) Designed exclusively for use in a lifeline system Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point can be installed on standing seam roofs made of steel, copper, aluminium or titanium zinc without penetrating the roof surface. Depending on the subsurface, this kind-to-your-roof device is attached using the aluminium or brass clamps supplied in the package. EN 795:2012, A + CEN/TS 16415:2017 Clamped onto two adjacent seams - completely penetration-free Seam intervals: 300 - 450 mm / 420 - 660 mm For steel and stainless steel ≥ 0.5 mm; copper ≥ 0.6 mm; aluminium & titanium zinc ≥ 0.7 mm For Rheinzink and similar systems; also suitable for copper standing seam panels (Cu) Incl. installation set

Request for a quote

TRAS MM

Germany

Email : trasmme@gmail.com SKYPE : TRAS MM ============================== ZAMAK INGOT Zamak alloys were developed for the first time in the United States in 1929. The word Zamak comes from the German acronym and represents the elements it is made of: Z for Zink, zinc, A for Aluminum, aluminum, MA for Magnesium, magnesium, and K for Kupfer, copper. At its very beginning, Zamak was used just for decorative applications; later, the strength of this material determined its success in many other productions.

Request for a quoteResults for

Zinc aluminum - Import exportNumber of results

11 ProductsCompany type