- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wheels

Results for

Wheels - Import export

ROLKO KOHLGRÜBER GMBH

Germany

In our extensive product range you will find high-quality wheels with foamed polyurethane tyres on plastic or sheet steel rims, in various sizes and designs - also ideal for industrial applications. Our PU tyres are made of solid material and are therefore absolutely puncture-proof. Nails, splinters and shards cannot harm the tyre. The wheels offer a high level of driving comfort, even on uneven floor surfaces. Our products are certified and tested according to the latest European norms and quality standards. You can find more information about our products and services in our online catalogues on our homepage. Do you have any questions about our products or would you like to request a quote? Please feel free to contact us. We have the right tyres for almost every application!

Request for a quote

ROLKO KOHLGRÜBER GMBH

Germany

Air-filled tyres offer a high level of driving comfort, even on uneven ground surfaces, and are characterised by their low dead weight combined with high load-bearing capacity. Our products are certified and tested according to the latest European norms and quality standards. Would you like to make your pneumatic tyres puncture-proof? No problem for us. With our Rolko-SMART tyre filling made of soft-elastic polyurethane, we make your wheels 100% puncture-proof, with comparable driving characteristics of a pneumatic tyre. You can find more information about our products and services in our catalogues. Do you have any questions about our products or would you like to request a quote? Please feel free to contact us. We have the right tyres for almost every application! Translated with www.DeepL.com/Translator (free version)

Request for a quote

ROLKO KOHLGRÜBER GMBH

Germany

In our extensive range of high-quality skate wheels in various sizes and designs, you will also find swivel castors and fixed castors with housings made of galvanised sheet steel - also ideal for industrial applications. Our products are certified and tested according to the latest European norms and quality standards. You can find more information about our products and services in our online catalogues on our homepage. Do you have any questions about our products or would you like to request a quote? Please feel free to contact us. We have the right tyres for almost every application!

Request for a quote

TORWEGGE GMBH & CO. KG

Germany

Our solid gravity-driven roller conveyors provide an optimized solution for the internal transportation of your lightweight or heavyweight products. In order to ensure that your conveyed goods flow smoothly and independently all the way from the inlet to the outlet point, the roller conveyor must have the proper declination. This factor must be determined individually according to the type of load carrier and weight of the goods being used for your application. We can also deliver complete solutions that are individually tailored to your requirements; our support already begins during the planning phase for your project. Take advantage of our in-depth experience and benefit from our assessment of your operating conditions and influencing factors (including the suitability of using roller conveyors for your goods) – Leave nothing to chance.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Application Rollers are particularly well suited to the transport of light conveyed material with a smooth and stable underbody. They are used in roller strips, roller tracks, flexible roller conveyors and curved conveyors. They are used in push-through rack storage systems, as deflectors and guide tracks as well as for interlinking different conveyance systems. Load The load-bearing capabilities can be found in the table of dimensions under the “Roller” tab. The conveyance speed of Schulz rollers is up to 2 m per second.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Custom pins for precision machinery.

Request for a quote

DEMAG CRANES & COMPONENTS GMBH

Germany

Our wheels and wheel block systems are designed and manufactured as modular solutions for a wide variety of applications. They are used in countless mobile devices and systems – as single components or as complete travel units. They demonstrate their high reliability and long service life in operation every day – with only a minimum maintenance requirement. Simple installation and alignment, favorable dimensions and a wide variety of versatile connection options make our wheel systems particularly cost-effective. The broad range covers wheel loads up to 60 tonnes. See all the performance details and benefits on the product pages.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Wood-Her rollers consist of an aluminum core. Light-colored rubber is used for the coating, in addition to the polyurethane materials that have long been tried and tested in the woodworking industry, and mainly the elastomer Vulkollan®. The core mounting holes have two side holes.As a service, we offer our customers the opportunity to have their used pressure and feed rollers re-upholstered by us. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design in smooth or grooved form and the most suitable degree of hardness must be determined by the customer. Weinig rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core mounting holes are designed as a keyway or with three side holes.The Weinig rollers are mainly coated with the elastomer Vulkollan® patented by Bayer. We would be happy to advise you by telephone or at your location regarding high-quality and cost-effective design of pressure and feed rollers.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Due to the ever-increasing level of automation, coated rolls and rollers are now used in almost all production facilities. These rollers and rolls are used in a wide variety of applications (transport, finishing, cleaning, coating, drying, etc.). What is particularly important is the quality of the coating, which determines the service life of the roller and the processing process.We manufacture completely coated rollers, i.e. We provide you with the roller core made of aluminum, steel, etc. and the desired coatings (rubber, Vulkollan®, etc.) from a single source. We can also roughly pre-grind your rollers, finely grind them or even provide them with grooves.As a cost-effective alternative, we also offer you to have your rollers recoated by us. Here too we can choose between different coatings (rubber, Vulkollan®, etc.). According to the customer’s wishes, we can also pre-grind, finely grind or provide these rollers with grooves. We would be pleased to advise you!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

With the newly developed FAPI-SWITCH series, we have succeeded in designing deflection pulleys in a lightweight system design with an unprecedented smoothness and smoothness of running that set new standards in the belt grinding process. Due to the flexibility, also with regard to different dimensions, belt elephant machines of all brands can be equipped with these deflection rollers. We would be pleased to advise you on which return pulleys can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

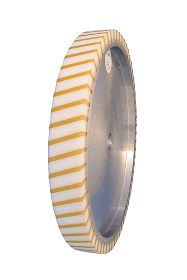

The choice of the right profile sanding wheel for wood sanding must be determined based on the customer’s requirements. Our highly experienced engineers and application technicians would be pleased to advise you by phone or email, on a high quality and cost-effective type of profile sanding wheel of the FAPI-SW series for your process. The profile sanding wheels FAPI-SW are made of the same material used for flap grinding wheels. The significant difference lies in the highly elastic surface of the profile sanding wheel FAPI-SW. This is achieved with individual, disconnected slitted, abrasive cloth packages separated by a large distance to one another and fastened to the wheel hub.

Request for a quote

GTC GMBH

Germany

Everyone knows that the key to a long and and troubleless operation of the engine is the use of high-quality motor oils and lubricants that meet the requirements of the vehicle manufacturer and its timely replacement. Buying oil and technical liquids from us, you can be confident in the quality of purchased products; then, our company is the official partner of such leading brands as CASTROL, MOTUL, VENOL, which is confirmed by the corresponding certificates. Our experts will help you choose lubricants, and prices will surprise even the most discerning buyer.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The choice of the right serrated grinding wheel for grinding knives, scissors, tweezers, pliers, surgical instruments, etc. with the most suitable teeth and the highest quality standards must be determined on a customer-specific basis depending on the intended use. The base body of the serrated grinding wheel is made of aluminum. A coating is applied to the aluminum body, into which the teeth are then inserted depending on the profile shape according to the intended use. With our many years of experience, we would be happy to advise you by telephone or on site regarding a high-quality and cost-effective design of a serrated grinding wheel for your process.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The FAPI-VU expander discs are an optimal grinding tool for working with all types of sanding sleeves. The expander discs are exclusively provided with a specially slotted coating made of foamed Vulkollan®, which means that the sanding sleeve is tensioned by centrifugal force during the processing process. In practice, the expander discs covered with foamed Vulkollan® (VU) are often simply called “expander discs with foam” or also sanding sleeve carriers.Advantages of expander discs with pararubber coating: - Wear resistance - Oil resistance - Grease resistance - Emulsion resistance We would be pleased to advise you on which expander rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The expander discs FAPI-PA are an optimal grinding tool for working with all types of sanding sleeves. The expander discs are exclusively provided with a specially slotted NBR coating, which means that the sanding sleeve is tensioned by centrifugal force during the processing process. In practice, the expander discs coated with the material NBR are often simply called “rubber expander discs” or also grinding sleeve carriers.Advantages of expander discs with pararubber coating: - Wear resistance - Oil resistance - Grease resistance - Emulsion resistance We would be pleased to advise you on which expander rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VUS/KS is a version coated with lamellae of foamed up Vulkollan® and plastic foam lamellae. The overall height of the coating must also be selected based on the respective application. The alternating lamellae of foamed up Vulkollan® and plastic foam lamellae make the contact wheel especially soft and adaptable. In practice, this contact wheel is used mainly for the finishing of lightly cambered or rounded workpieces. The different material densities result in the heat generated during grinding being drawn off very effectively. Advantages The contact wheels of the FAPI-VUS – series are coated only with lamellae of foamed up Vulkollan® Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

As the name indicates, the aluminium hub of the contact wheel FAPI-VU SMOOTH is coated with a coating of a smooth lamellae of foamed up Vulkollan®. The coating height can be varied depending on the application. Advantages The contact wheels of the FAPI-VU – series are only coated with a lamellae of foamed up Vulkollan®. Lamellae of foamed up Vulkollan® is cellular Vulkollan®, a polyurethane foamed with water which has very high dynamic properties. Lamellae of foamed up Vulkollan® can be identified by its slightly yellowish colour. Benefits of contact wheels coated with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VU MILLED is the addition to the smooth model. This is accomplished by milling grooves into the coating of lamellae of foamed up Vulkollan®. The overall height of the coating is also adapted to the respective application and is therefore variable. The grooves can be cut into the coating in various widths, depths and angles. Due to the grooves inserted, contact discs with a milled design are significantly more aggressive than contact discs with a smooth design. The aggressiveness effect of the contact disk can be optimized for each application through an optimal groove width-groove depth-web width ratio so that high-performance processes are possible. With this contact disc, too, no signs of fatigue occur after long, intensive use if used properly.The contact discs of the FAPI-VU series are exclusively provided with a coating made of foamed Vulkollan®. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PUS/KS is an extremely soft version of a contact wheel with a polyurethane foam and plastic foam lamella coating. The overall height of the coating must also be selected based on the respective application. The alternating polyurethane and plastic foam lamellae make the contact wheel extremely soft and particularly adaptable. In practice, this contact wheel is used mainly for the finishing of strongly cambered or rounded workpieces. Because of the different material densities and the spacing between the lamellae heat dissipates very well during the grinding process. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PUS OPEN is a further development of the dense design. Here the aluminium core is coated alternately with a long and short polyurethane foam lamella. The overall height of the coating is also adaptable to the respective application and is therefore variable (standard: 35 mm). Because of the variant of the open design, the abrasive belt can better cool because the heat from the belt sanding process is better dissipated. Through the precise adaptation of the extremely soft running cushion to the workpiece that shoud be found it is possible to achieve high-performance results when finish grinding. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

With the contact wheel FAPI-PUS DENSE, the aluminium hub is coated with dense adjoining polyurethane foam lamellae. The height of the coating resp. the length of the polyurethane foam lamellae can be varied depending on the application (standard: 20 and 35 mm). The polyurethane foam lamellae provide the contact wheel with a “running cushion” with which a fine finish is possible especially when working on (strongly) cambered and profiled parts. The coating adapts to every workpiece to be found. In addition, the contact wheel FAPI-PUS dense contributes in large measure to abrasive belt cooling because the spaces between the lamellae dissipate the heat generated during belt grinding. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

As the name indicates – the aluminium hub of the contact wheel FAPI-PA SMOOTH is coated with a smooth para rubber coating. While a coating height of 20 mm has established itself as the standard, the coating height is variable as desired. The smooth design of the contact wheel is suitable for the heaviest grinding and roughing. It is also attractive due to its long service life. Advantages The contact wheels of the FAPI-PA – series are coated only with para rubber. The para rubber (PA) coated contact wheels are in practice often simply called “rubber coated contact wheels” or rubber contact wheels. Benefits of contact wheels with this design: Highest service life Wear-resistance Oil-resistance Grease-resistance Emulsion-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PA MILLED is the addition to the smooth model. At this type grooves will be milled in the rubber coating.The grooves can be milled into the coating in various widths, depths and angles. The total height of the covering can also be selected variably, with the standard height proven in practice being 20 mm. The higher the covering, the more elastic and therefore softer the contact disk surface appears. Due to the milled grooves, the contact disks are much more aggressive than smooth contact disks. The aggressive effect of the contact disk can be optimized for each application through an optimal ratio of groove and web width so that high-performance processes are possible. This contact disc also impresses with its longevity.The contact disks of the FAPI-PA series are exclusively provided with an NBR coating. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Lamellae of foamed up Vulkollan® and plastic foam are attached alternately to the aluminium hub of the contact wheel FAPI-KS/V. While the width of the lamellae of foamed up Vulkollan® should be kept constant, the width of the plastic foam lamellae can be varied. The wider the plastic foam lamella is, the more aggressive the contact wheel will be. The height of the coating or the length of the lamellae of foamed up Vulkollan® and plastic foam can be varied depending on the application (standard: 25 mm). The longer the lamellae are, the less rigid the material becomes, which in turn reduces the aggressiveness of the contact wheel. Advantages Because of their lamellae of foamed up Vulkollan® and plastic foam, contact wheels of the FAPI-KS/V – series are extremely aggressive contact wheels. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

As the name indicates, the aluminium hub of the contact wheel FAPI-VUS DENSE is coated with dense adjoining lamellae of foamed up Vulkollan®. The length of the lamellae of foamed up Vulkollan® can be varied depending on the application (standard: 20 and 35 mm). The lamellae of foamed up Vulkollan® provide the contact wheel with a “running cushion” with which a fine finish is possible especially when working on (strongly) cambered and profiled pieces. The coating adapts to every workpiece to be found. In addition, the contact wheel FAPI-VUS dense contributes in large measure to abrasive belt cooling because the spaces between the lamellae dissipate the heat. Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design and construction This Schulz ball caster / air cargo unit consists of a casing and top cover as solid turned parts, a bearing ball and several support balls. Special model with separate ball cup as an airport ball caster. Dimensions The spacing is calculated by dividing the shortest edge length of the object to be transported by 3.5.

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For loosening, cutting and attaching balance weights • For opening and pressing together the retaining springs • With cutting edge for separating the balance weights • Made of special tool steel, forged, oil-hardened

Request for a quote

CRAEMER GMBH

Germany

The 120 - 360 l MGBneo are an economic solution for modern waste management companies. They comply with DIN EN 840 and RAL-GZ951/1 (GGAWB) and are noise reduced according to EU directive 2000/14/EG. Characteristics: — Optimised construction for an economic use of storage space — Stacks of up to 13 (selected bin sizes) enable cost saving potential for transport and storage processes — Robust thanks to uniform wall thickness and reinforcement of all walls — Large printing area offers space for individual labelling — Release pins allow quick and easy lid replacements — DDA notch option for ease of bin identification — Coloured lid inserts for optional colour-coded identification — External wheels, available with 200 or 250 mm Ø rubber tires

Request for a quoteResults for

Wheels - Import exportNumber of results

72 ProductsCompany type

Category

- Wheels, castors and rollers (28)

- Industrial tools (12)

- Dustbins, waste bins (11)

- Wheels, castors and rollers - rubber (9)

- Domestic waste treatment (7)

- Wheels, castors and rollers - metal (5)

- Tyres and accessories (3)

- Tyres (2)

- Toothed wheels (1)

- Gears (1)

- Wheels and castors for industrial trolleys (1)

- Conveyor systems (1)

- Aluminium and aluminium alloys (1)

- Axles, vehicle (1)

- Rehabilitation apparatus and equipment (1)

- Tyres and bands for wheels, castors and rollers (1)

- Wheels, special (1)

- Boat trailers (1)

- Carbon and graphite - electrical components (1)

- Components and parts for small household appliances (1)