- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- weight loss

Results for

Weight loss - Import export

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

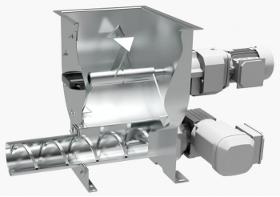

— Loss-in-weight feeder for powders and pellets — Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — Separate screw and agitator motors (3 phase AC gear motors), — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range - Different Versions 4-3743 dm³/h 20-3743 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Details depend on the characteristics of the medium to be fed (density, viscosity, solids content, temperature, reactivity, toxicological properties, etc.) and the respective process requirements (accuracy, feed rate, turndown ratio, counterpressure, etc.) —Applicable feed pumps: piston, diaphragm, gear, hose, rotary piston or eccentric screw pumps, etc. — High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy — Heated versions available (electrical, hot water, thermal oil, etc.) Power range - Different Versions 1 - 1000 dm³/h 50 - 5000 dm³/h 100-10000 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — 3 phase AC gear motors — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 1-298 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at mid feed rates — Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range - Different Versions 4-2693 dm³/h 20 - 2693 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at mid feed rates — Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 50-7500 dm³/h

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Universal loss-in-weight feeder for virtually all flowable ingredients (powders, pellets, flakes, fibers, etc.) — Flexible polyurethane hopper agitated by amplitude adjustable paddles for consistent screw filling and mass flow of ingredient without degradation — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates — Optional separate paddle motor to allow paddle speed adjustment for difficult flowing ingredients (not available for FW20) Power range - Different versions 1-25570 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— No stirring agitator or other rotating parts for ingredient flow without degradation — Vibration amplitude feedback ensuring linear conveyance characteristics over the entire feed rate range Power range 10 - 450 dm³/h 20 - 1000 dm³/h 300 - 3000 dm³/h 650 - 6500 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

* Loss-in-weight FiberXpert feeder for long and uneven fibers (natural fibers, wood fibers, carbon fibers, etc.)* Also suitable for film chips and shredded film strips cut off by film edge trimmers * Technical features: special fiber screw, large steep walled hopper, novel design and special position of the stirring agitator in the hopper * High-tech weighing system with digital load cell or * high-resolution strain gauge load cell for high weighing accuracy Power range 200-19900 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Stainless steel hopper with stirring — agitator for consistent screw filling and mass flow of ingredient — Separate screw and agitator motors (3 phase AC gear motors), — except model DSR28 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 50-7088 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Feeder ideal for difficult flowing, sticky or floodable bulk ingredients at low feed rates — Separate screw and agitator motors (3 phase AC gear motors), except models MT and DDSR20 — Interchangeable screws and screw tubes allowing quick adjustment to changing ingredients and feed rates Power range 1-489 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Slide gate valve for solids flow on/off control, mainly used as an automatic valve for loss-in-weight feeder refill — Double acting pneumatic drive — Readily mounted 5/2 way solenoid valve Diameters - Different versions 80–400 mm (3.1–15.7 in)

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— RS 485 interface for internal Brabender fieldbus — Application software for DDW (loss-in-weight feeder), DBW (dosing belt scale) or Coriolis flow meters — internal pluggable fieldbus connection — can be controlled via the OP1, OP6 and OP16

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Filtering of displaced air during loss-in-weight feeder refill — Filter cartridge with filter material made of polyester fleece (conforms to FDA and GMP directives) — Trapped dust is automatically cleaned by pulses of compressed air (dust falls back into the feeder eliminating ingredient waste) — Models available for hoppers up to 1000 dm³ (35.3 ft³)

Request for a quote

STRONG MAGNETS GMBH

Germany

The corrosion resistance of Neodymium magnet is considered poor, surface coating is highly recommended for Neodymium magnets. With the expansion of elevators, wind turbines and permanent motors application, the users need higher requirement on corrosion resistance of Neodymium magnet, as the glue cohesiveness of unplated magnet is much better than plated magnets, also unplated products are better in the security. Now, more and more customers tend to use unplated magnets, upon this condition we have developed ultralow weight loss magnets after the continuous innovation and study. Normally, the weight loss test is over 150mg/cm² in the industry of Neodymium magnet, this will be different for magnets produced from different material formulation and manufacturing process. A lot of our new magnets can reach to 1mg/cm², (Testing condition HAST standard for 168hrs), due to its very low weight loss, the corrosion resistance is excellent

Request for a quote

FILLTECH GMBH

Germany

Filling plants and bottling from a single source Use our services and lay back. At Filltech, we can ensure gas filling services at custom-made aplications maintained and controlled at our premises. Gases for food and industrial applications, noble and special gases and different gas mixtures are filled accurately in different cylinders or containers. CO 2 cylinders for soda If you would like to know what tailor-made systems can achieve andhow many benefits they provide, we like to share our customer cases with you. In the food industry, for example, we cooperated with a soda supplier. We developed and manufactured a fully automatic filling plant. Up to 1,000 cylinders per hour can be drained, flushed and refilled automatically. An integrated leak test, a 100-percent weight loss and the acquisition of all the highest quality padding ensure a high quality process. Special software for monitoring and documenting the production parameters, developed by Filltech, ensures all statutory proc

Request for a quoteResults for

Weight loss - Import exportNumber of results

16 ProductsCompany type