- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water%20treatment

Results for

Water%20treatment - Import export

TECHNOTRANS SOLUTIONS GMBH

Germany

Lime and corrosion are hidden cost factors. Inevitably, these two “enemies of temperature control channels” prolong the cooling time, reduce the process safety and have a negative influence on the parts’ quality. The problem occurs insidiously in each plastic processing company, because lime and corrosion gradually build an insulation layer in the cooling channels and are thus responsible for a deteriorating heat transfer. Often the problem is not recognized until the demanded parts’ quality cannot be achieved any longer or if the complete system breaks down. The effect of cleaning the cooling channels of an injection mould is a reduction of cooling time up to 40 % (in individual cases even more), depending on the amount of deposits. The latest development, easy to use by the processor himself, is moldclean, a compact appliance which cleans polluted cooling channels in injection moulds and heat exchanger systems.

Request for a quote

JOSEF JASPER GMBH & CO. KG

Germany

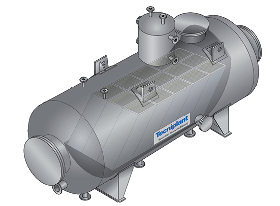

We draw on vast experience in manufacturing of tanks for municipal and industrial watertreatment. For example filter tanks, oxidizers, activated carbon filter, pressurised waterholding tanks, compressed air tanks, reactors as well as nitrification and denitrification tanks.

Request for a quote

IGUS® GMBH

Germany

- Low-maintenance system for travel up to 100 m - Other sizes and versions available, travel up to 200 m and more with E2 roller e-chains® - Protection against weather and dirt exposure - Cost-effective and fully enclosed complete solution - Standardized and modular design - Simple wall assembly or optional floor mounting - Cable lengths up to 50% shorter than festooning, low-profile installation and no cable junction - Cables are at all times guided with a defined bending radius, and tensile forces are absorbed by the e-chain® - Cables cannot hook, jam, or tear - No slip ring contacts (as is the case on motor drums) -Cables or hoses can easily be retrofitted at any time Reduce electricity costs - direct drive due to scraper, no additional drives needed (as is the case on motor drums) Scraper arm (e.g. as mechanical connection to the scraper carriage) optionally available - we document the situation on-site and will propose a customised solution

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT's own filter technology is innovative and fast-growing. Why are we involved in filter technology? The answer is simple: high pressure cleaning technology using water as an environmentally friendly medium requires a high quality filter and recycling solution. In some cases, traditional filter manufacturers are unable to meet these requirements, which is why KAMAT also offers its own customer-specific solutions in the field of filter technology. High-pressure water cleaning technology has many advantages: A water jet can be used gently on the surfaces to be cleaned, water is generally available as a medium and at the same time is environmentally friendly without extensive delivery costs. When it comes to accessories, high pressure cleaning systems have special requirements that are difficult to meet. For this reason, KAMAT has developed its own customised high-pressure filter solutions. KAMAT high pressure filters are available for operating pressures up to 4,000 bar.

Request for a quote

KAMAT GMBH & CO. KG

Germany

High-pressure cleaning and surface preparation with water requires precise management of the water jet. This precise management is necessary to ensure that the required result (e.g. surface finish) is achieved within a reasonable time. The method must be safe and fatigue free. With this in mind, we offer a specially designed and manufactured range of high pressure guns with electrical or mechanical control. The exceptional ergonomics of these tools have been achieved through innovative detail solutions: For example, our high-pressure guns are equipped with a special swivel handle that transmits any torque to the wrist. In addition, the hose connection can be swivelled in all directions, allowing optimum hose routing for all working situations. Our range of high pressure guns is complemented by various versions of foot valves, rotating gun lances, rotating nozzles and other accessories for a wide variety of applications, such as pipe cleaning.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OGE GROUP

Germany

Oily Water Treatment Package Oily Water package is designed to separate a huge amounts of oil and suspended solids from the wastewater effluents of oil refineries, petrochemical plants, chemical plants, natural gas processing plants and other industrial sources.

Request for a quote

OGE GROUP

Germany

API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants

Request for a quote

OGE GROUP

Germany

API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants

Request for a quote

OGE GROUP

Germany

API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants

Request for a quote

OGE GROUP

Germany

API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants

Request for a quote

OGE GROUP

Germany

API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants

Request for a quote

OGE GROUP

Germany

API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants API Separators CPI – Corrugated Plate Interceptor IGF – Induced Gas Flotator Drum Vacuum Filters Vacuum Belt Filters Flotators Oily Water Treatment Water Treatment Plants

Request for a quote

OGE GROUP

Germany

CPI Separator Corrugated Plate Interceptor – allows the separation in the oily water treatment of the suspended solids and of the oil globules from water by gravity separation principle that is based on the difference of specific gravity between the phases (oil, solid, water).

Request for a quote

OGE GROUP

Germany

Solid Water Treatment Package We developed a Solid-Liquid Separation System to optimize the plant configuration in order to achieve a competitive solution, suitable to make the transportation and installation process more economical, and to provide benefits for the operating and maintenance activities.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

You require a mobile steam plant or you want to install a steam plant outside your plant building? Then the complete installation within a container is the ideal solution for you. The container steam plant contains all the required components – from the water treatment plant through to the steam trap. - CERTUSS steam generator - CERTUSS CVE supply unit - Feed water treatment - Steam distributor - Pressure reducer station - Clarification valve - Steam dryer - Condensate elevating system - Steam trap - Interior lighting of the container - Insulated pipe installation in the container - Emergency-off switch - Steel door or uPVC door - High-quality stainless steel wall with insulation - Outside coating as required The installation and commissioning of the container plant at the customer is on request either carried out completely or only partially (if an external installation company is used) by our customer service.

Request for a quoteResults for

Water%20treatment - Import exportNumber of results

16 Products