- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water cleaning

Results for

Water cleaning - Import export

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This machine provides high efficiency cleaning of medical and technical elastomers and is construed for big sized batch demands at high throughput. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. For industry 4.0 demands, the W90 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. By special request, siliconisation of rubber parts or coating with other glide agents is additionally possible. The W90 offers maximum economic efficiency on treatment of big batch volumes at high throughput!

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This machine offers high efficiency cleaning of medial & technical elastomers and is construed for mid sized bach demands. The W40 is, like any of our machines, designed for high performance with economic efficiency. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. For industry 4.0 demands, the W40 is best prepared. On option, the control of the machine via OPC-UA server can be installed additionally. By special request, siliconisation of rubber parts or coating with other glide agents is additionally possible. The W40 is the optimal solution for mid-sized batch demands at high througput!

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This small-sized machine can be integrated into the production line easily. This safes temporary storage or extra transports and finally corresponding time loss and costs. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. By special request, siliconisation or coating with other glide agents is also possible. The W30 uses exchangeable bastekts for the (un)loading. These baskets are also compatible to our cryogenic deflashing machine E30W, and furthermore, optimally suited for a linear in-line processing → production → deflashing → washing → postcure tempering, The W30 is best pepared for industrie 4.0 demands. (on option with OPC UA server) With this small-sized machine, your treatment capacity is at best cost-performance ratio!

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This automatic washing & drying system provides high efficient cleaning of elastomers in through-feed method (on option washing with de-ionized, de-mineralized or ultra-pure water possible). Starting from the loading station, the washing drums are conveyed automatically to each washing station (→ station pre-washing → station rinsing → station high pressure cleaning → station high pressure drying) and are finally conveyed to the unloading station after treatment. The dimensions of this system depend on the drum dimensions desired (perforation from 3 - 15 mm possible by choice). Set as our default, the models WD3, WD5 and WD9 are available with different sizes. For industry 4.0 demands, this system is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. Siliconisation or other coating of elastomers is possible on option.

Request for a quote

TROTEC GMBH

Germany

A few practical benefits: Fragrance diffuser- for perfect well-being the B 25 E distributes the fragrance which you choose thanks to scented oil tank No clogging of the filter thank to integrated scented oil tank 4 fan stages- for individual setting for your needs Automatic switch-off by full water tank- reduce the power consumption Integrated Hygrostat with 5 humidity values- easy setting up of a well-being Filter change indicator Lime and germs remain in Filter Night mode with dimmed LEDs, for uninterrupted sleep Holder for Secosan Stick- keeps the water clean and uncontaminated 360° distribution of air- the humidified air is evenly distributed in the entire room Refillable with normal tap water- the distilled water is not needed Very quiet operation Big water tank – 3 liters Low power consumption Also suitable for workplace, because it is very stable despite of small and compact dimensions Filters in scope of delivery

Request for a quote

TROTEC GMBH

Germany

Healthy air and wellness for the airwaysBreathe deeply and feel healthy! Thanks to a combination of refreshing humidification, permanent air purification and room air aromatization, the ultra-silent 3-in-1 ultrasonic humidifier B 7 E helps to improve the room air quality and maintain a healthy indoor climate with a wellness factor. The room humidity level is regulated fully automatically to a healthy comfort range (40 – 60 %), freed from dust, pollen and unpleasant odours in the integrated carbon air filter and, if desired, additionally aromatized with a subtle fragrance. The UV lamp in the water tank keeps the water clean and up to 97.9 % free from germs. Why is air improvement necessary at all? Whether we feel comfortable at home, sleep through the night or are receptive and productive at the workplace depends decisively on the quality of the room air.

Request for a quote

INFICON GMBH

Germany

Clean water is essential for life. As more chemicals are introduced to the environment, adverse consequences to water quality and corresponding health impacts will increase as well. In order to provide the highest level of safety and security, a fast response to water quality issues is necessary. The CMS5000 is a GC-based system that autonomously samples VOCs in water, quantifies contaminant levels and automatically alerts users if thresholds are exceeded.

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

A more economic solution for an environmentally sound condensate management is the decentralised oil-water separation directly at the source. Condensate which was processed with ÖWAMAT can be directly introduced as cleaned water into the sewerage system. The devices have a national technical approval and do not require a permit according to the law on water. In addition, the ÖWAMAT oil-water separators do not create any energy costs, boast enormous filter service lives and can be retrofitted into older systems without difficulty.

Request for a quote

KAMAT GMBH & CO. KG

Germany

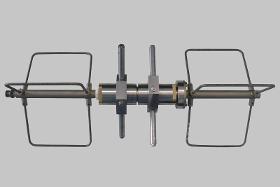

The nozzle consists of two counter-rotating nozzle housings into which the nozzle tubes are inserted with a connection for screw-in round jet nozzles. A special packing sealing system inside the nozzle housings ensures protection during operation and prevents the ingress of contaminants. In front of and behind the nozzle housings are spacers (basket system) to prevent the nozzle tubes from hitting the well wall. In addition, for best cleaning results, the temperature of the medium should be between 3 and 30°C.

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT's own filter technology is innovative and fast-growing. Why are we involved in filter technology? The answer is simple: high pressure cleaning technology using water as an environmentally friendly medium requires a high quality filter and recycling solution. In some cases, traditional filter manufacturers are unable to meet these requirements, which is why KAMAT also offers its own customer-specific solutions in the field of filter technology. High-pressure water cleaning technology has many advantages: A water jet can be used gently on the surfaces to be cleaned, water is generally available as a medium and at the same time is environmentally friendly without extensive delivery costs. When it comes to accessories, high pressure cleaning systems have special requirements that are difficult to meet. For this reason, KAMAT has developed its own customised high-pressure filter solutions. KAMAT high pressure filters are available for operating pressures up to 4,000 bar.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Lime and corrosion are hidden cost factors. Inevitably, these two “enemies of temperature control channels” prolong the cooling time, reduce the process safety and have a negative influence on the parts’ quality. The problem occurs insidiously in each plastic processing company, because lime and corrosion gradually build an insulation layer in the cooling channels and are thus responsible for a deteriorating heat transfer. Often the problem is not recognized until the demanded parts’ quality cannot be achieved any longer or if the complete system breaks down. The effect of cleaning the cooling channels of an injection mould is a reduction of cooling time up to 40 % (in individual cases even more), depending on the amount of deposits. The latest development, easy to use by the processor himself, is moldclean, a compact appliance which cleans polluted cooling channels in injection moulds and heat exchanger systems.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Up to three processes – cleaning, painting and drying in one booth. Multi-process booth Just one booth for cleaning, painting and drying (up to three processes). Dry paint filter and wet cleaning in one booth – that is actually a contradiction in itself. Thanks to the separate air guidance, the exhaust air is fed downwards through the grating when drying and laterally through the filter boxes when painting, so that very little moisture enters the dry filter and virtually no particles get into the cleaning water. In order to prevent the ingress of particles, the gratings can additionally be covered over during painting. Any paint that does get into the cleaning water is usually already dry, so that no dilution in the classic sense takes place; instead, it behaves like small, filterable plastic balls. Advantages:

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Jerko preparation systems are specially adapted to the requirements of forging and die casting lubricants Efficient cleaning of water-soluble lubricants. The preparation of dispersions or suspensions is also possible. AND Reduce disposal costs by cleaning process water. The treatment plant is the economically optimal supplement to our efficient spraying systems. With a Jerko treatment plant you can save up to 80% of lubricant and disposal costs. In many cases the ROI is less than one year! Score points with new, innovative solutions at your next environmental audit! From manual to fully automatic reprocessing, Jerko develops the right solution together with you.

Request for a quote

DALMINEX GMBH

Germany

Installation piece for clean drinking water

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

FULLY AUTOMATIC CENTRIFUGATION FOR CLEANING YOUR PROCESS WATERThe PLC-controlled peeling centrifuges of the ZA range are your reliable aid for fully automatic process water cleaning. The sludge is separated in a rotating drum and automatically peeled off into a sludge tank. You can set the cleaning cycles individually. MODULAR DESIGN FOR INDIVIDUAL SOLUTIONS The ZA range features a modular design, allowing you to flexibly adjust it to your needs. Select the dirt and process water tank, available in a range of sizes, as well as the additional process water pumps, dosing units or a heat exchanger, suitable for both the ZA 04 and ZA 06 configurations. THE BENEFITS AT A GLANCE Centrifuges with up to 2,417 times the acceleration of gravity PLC for fully automatic operation Two configurations: ZA 04 with a cleaning power of 1,000 l of process water per hour ZA 06 with a cleaning power of 2,000 l of process water per hour

Request for a quote

MAYFRAN GMBH

Germany

The AT-Cleaner coolant filtration system offers advanced cleaning for water-soluble coolants using a proprietary hydraulic centrifugal separator that is media and maintenance-free. The media-free design offers for significant savings on consumables and downtime versus typical bag filters. The cleaner coolant, to 10-15 microns, increases coolant, pump, and tool life while improving part accuracy and finish.

Request for a quote

SHANGHAI SHINJO PUMP CO.,LTD.

Germany

General QJ/QJR Submersible Borehole Pump (Deep Well Pump) designed for pumping clean water from deep wells, rivers, reservoirs and mines etc., as well as applications in industrial water supply , agricultural irrigation projects. Fire fighting and so on. QJR is specially designed for geothermal applications featured by heat-resisting, anti-corrosion and anti-aging properties, water temperature up to 90℃ Construction & Features Compact vertical centrifugal multi-stage design with perfect standardization and generalization, easy operation and convenient maintenance. A complete electric submersible pump includes a water pump set, electric motor, a discharge piping, water-proof cable and a control panel. Submersible motor filled with clean water for cooling and lubrication. And the pressure regulation switch, located at the bottom of motor, shall automatically operate to balance the pressure fluctuation caused by temperature variations.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Water cleaning - Import exportNumber of results

17 ProductsCompany type