- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vibration dampers

Results for

Vibration dampers - Import export

RG + SCHWINGUNGSTECHNIK GMBH

Germany

Depending on type, multi-directional dampers can be loaded in every axis. In our standard vibration dampers of the GDZ series two all-metal cushions are installed. Depending on the assembly, these cushions are load with pressure or tension. Vibration dampers of the series 7 have another cushion obstructed which allows them to absorb load in horizontal direction additionally. Because of this, GDZ dampers are perfectly suitable for applications in the fields of plant engineering and rail vehicle construction. Our product range includes three different types of these multi-directional dampers: GDZ series 1 for a fixation with bolts for pressure and tension load GDZ series 5 for a welding fixation for pressure and tension load GDZ series 7 for a fixation with bolts for pressure, tension and horizontal load

Request for a quote

RG + SCHWINGUNGSTECHNIK GMBH

Germany

Damping cushions made of stainless steel are knitted and pressed in a special process. Depending on size, density and design it can be loaded in a range between 5 and 20.000 kg. It can be pressed in cylindrical or rectangular shape. Versions with bunches and steps are available. Standard materials are 1.4301 and 1.4404. Additional materials and special designs are on demand. RG+ offers the following damping cushions as standard elements: GKK as a vibration damper in cylindrical form GKR as a vibration damper in rectangular form GKB as a vibration damper with a bunch

Request for a quote

RG + SCHWINGUNGSTECHNIK GMBH

Germany

Vibration damper of the series GMF are especially designed for machine tools. The elements GMF-( )-4 are made to mount small presses or cutters. Depending on the size of the elements they have a load range between 250 and 10.000 kg. Vibration damper of the series GST have an own levelling integrated, so they can compensate small unevenness on the floor. Our product range includes three different types of machine feet: GMF-( ) as a vibration damper especially for machine tools GMF-( )-4 as a vibration damper especially for small presses GST-( ) as a vibration damper with integrated levelling

Request for a quote

RG + SCHWINGUNGSTECHNIK GMBH

Germany

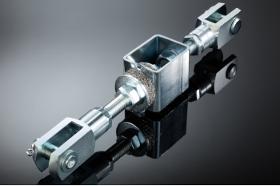

Vibration dampers of the series GAB are especially used to stabilize your pipe system. You can use these elements to absorb thermal expansion of the pipes, too. These elements are often used in the field of plant engineering. Depending on the chosen series you are able to couple your system with this elements by a welding profile or a fork head. RG+ offers these suspensions in the following designs: GAB-( )-2 with one fork head on each site GAB-( )-5 with one fork head on one site and a welding profile on the other

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

Homogeneous rubber materials for a wide range of other possible applications With our new soft rubber division, we are opening up another interesting and important product field of modern rubber processing - that of homogeneous elastomers. Compared to our cellular materials, these homogeneous rubber materials offer a wealth of additional possible uses. What is soft rubber? The homogeneous elastomers from our soft rubber division seal particularly reliably at high closing and loading pressures. Mixtures of NR, CR, EPDM, NBR, fluorine and silicone, strengths of 30-80 Shore A offer you a wide range of applications. From simple pipe connections or flexible vibration dampers to complex components in automobiles - in all cases they take on important tasks for the durability and function of the entire system. You can therefore rely on the quality and durability of KOPP soft rubber. Modern process technology and careful quality control guarantee high durability and cost efficiency.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TRANSITEC ANLAGENBAU GMBH

Germany

The container emptying station consists of a frame to fix on the ground, a vibrating frame fixed on vibration damper, and one product reception hopper. Depending of the flow properties of the product, this hopper will be designed in conical shape to fix a spiral conveyor (in cas of good flowing product) or in cylindrical shape with an anti-bridging and metering device DZR DM or ZFP DM (for bad flowing products) The vibrating frame ensures the discharge of the product out of the container into the hopper. The anti bridging and metering device DZR beneath the hopper ensures the discharge of the product out of the hopper und doses the product at the same time to the place the product is needed. Depending of the conveying distance, one or more intermediate conveyors have to be set in place. This unit is standardly conceived for rigid containers with a capacity up to 2 m3 or 2 tons. The metering throughput reaches from few liters per hour up to 20 m3/h

Request for a quoteResults for

Vibration dampers - Import exportNumber of results

7 ProductsCompany type