- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- touch panel

Results for

Touch panel - Import export

TRANSFLUID® MASCHINENBAU GMBH

Germany

Compact and very efficient. Our fully hydraulic mandrel bending machine delivers outstanding bend quality and very simple handling, with SPS control for preselection and storage of bending angles via a touch panel.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The machines are extremely robust and easy to operate. A selection of setups is available to process tubes of different lengths, with an operational length up to 240“ Our compact and mobile bending machines can now be controlled easily with a touch panel. This opens up new possibilities, like displaying the comparison of target and actual values for all axes. Control of the tolerance of the length and the rotation means very little involvement for the operator during the manufacturing of tubes. Accessories are available, like an integrated saw, a de-burring device, a flaring tool and a compression-fitting swaging tool.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The machines are extremely robust and easy to operate. A selection of setups is available to process tubes of different lengths, with an operational length up to 240“ Our compact and mobile bending machines can now be controlled easily with a touch panel. This opens up new possibilities, like displaying the comparison of target and actual values for all axes. Control of the tolerance of the length and the rotation means very little involvement for the operator during the manufacturing of tubes. Accessories are available, like an integrated saw, a de-burring device, a flaring tool and a compression-fitting swaging tool.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The machines are extremely robust and easy to operate. A selection of setups is available to process tubes of different lengths, with an operational length up to 240“ Our compact and mobile bending machines can now be controlled easily with a touch panel. This opens up new possibilities, like displaying the comparison of target and actual values for all axes. Control of the tolerance of the length and the rotation means very little involvement for the operator during the manufacturing of tubes. Accessories are available, like an integrated saw, a de-burring device, a flaring tool and a compression-fitting swaging tool.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 645 - for tube-Ø 6 - 45 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Accurate forming with fast tool change. Our type REB axial t form forming machines, with their compression power of up to 1,300 kN are particularly wellsuited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step userfriendly and fully programmable individually. We offer the option to equip our systems with electric or hydraulicnumerical drives. These forming processes can be completed stepwise in transfer system to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 420 - for tube-Ø from 4-20 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 660- for tube-Ø 6 - 60 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

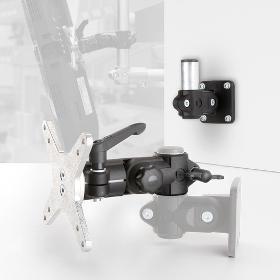

VESA or universal mount for connecting monitors, displays or control panels Monitors, touch screens, displays and control panels are used every day, and not just in the office. Industrial machines and systems are programmed or performance data displayed on modern touch screens or control panels. In utility vehicles, camera monitoring systems facilitate resetting and navigation devices make positioning possible. On conveyors, monitors make it possible to monitor and visualise all sorts of processes. Today, control panels or flat screens are often an essential component of modern assembly workstations, too.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

Glass surfaces are extremely smooth and meet high hygiene requirements. They are more resistant than plastic and have a high temperature, as well as high chemical resistance. In addition, glass decors ensure a design-oriented and high-quality finish. We offer molded glass parts for a variety of industrial and electronic applications. These include, for example, cover glasses and decor glasses for electronic products and protective glasses for displays. The glasses are usually made of float glass or white glass and thermally hardened ESG glass. The strength is from 0.55 to 19.0mm. For applications in the field of display protection, we also offer ultra-thin chemically hardened front glasses (0.3 – 8.0 mm). Other types of glass include borosilicate glass, quartz glass, magic mirror glass and touch panel glass.

Request for a quote

TROTEC GMBH

Germany

The T660 is a moisture meter that you can connect to a PC with the use of a USB cable. The MultiMeasure Studio Software, free in the service/ download section of company website, can be used to measure values from the T660, online and in real time on any PC. The values of this item can be saved for later analysis and for use in report. There are a few practical benefits, with the measuring device being designed and produced in accordance to the highest quality standards. There are two premium components, constructed with the IP54 rating. The item comes with an easy to lean glass surface made of high scratch-resistant. The capacitive touch screen control panel and the high resolution color display for simultaneous indication of two measured values is another major advantage, while the quick and non-destructive determination of near-surface moisture distribution is another major advantage.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

RK monitor mounting – high-strength, flexible and individually adaptable VESA or universal mount for connecting monitors, displays or control panels. Monitors, touch screens, displays and control panels are used every day, and not just in the office. Industrial machines and systems are programmed or performance data displayed on modern touch screens or control panels. In utility vehicles, camera monitoring systems facilitate resetting and navigation devices make positioning possible. On conveyors, monitors make it possible to monitor and visualise all sorts of processes. Today, control panels or flat screens are often an essential component of modern assembly workstations, too. Standard systems are generally designed for office applications. Industrial environments push these monitor mountings to their limits. For example, they normally can carry loads of only six to twelve kilograms and are not robust enough for use on machines, systems or assembly workstations.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Special machines for the automotive and supplier industry Machine system for low pressure molding - electronics casting The BASEline series combines a compact design and convenient operation and can be used optimally for the majority of low pressure molding projects. Various mechanical components can be put together depending on requirements. The adapted melting device with double-acting piston pump, 4l tank volume and a melting capacity of approx. 1kg/h enables optimal processing of small to medium shot weights and/or quantities. The available clamping force of 9/12kN is suitable for casting surfaces up to approx. 3,000mm². By using the Siemens S7-1200 control with touch panel, the series offers the same ease of use as the larger series.

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Connection via the Brabender fieldbus * Host computer interfaces — A maximum of 6 components — Operation of CM-E, CB-E, CB-S

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Connection via the Brabender fieldbus — Host computer interfaces — Operation of CM-E, CB-E, CB-S — A maximum of 16 components — Recipes, diagrams, protocols

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Compact component operation — Connection via a separate RS485 interface — Maximum 1 component — Operation of CM-E, CB-E — 5,7“ Color-Touch-Display

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The VEN BRUSH system technology is based on high pressure at low speed. Special hold-down brushes with wide support brushes or narrow support brushes for processing profiled workpieces, ensure the required pressure. For the pretreatment of workpieces of varying shapes or extremely fluctuating sizes, maximum perfection and flexibility are provided by the motor-driven height adjustment of each individual unit as well as by the infinite rotational speed setting. The high-performance vacuum transport belt ensures reliable transport and holds both small as well as large format workpieces in place. A Molton roller is built in to ensure constant cleaning of the conveyor belt. Unit diversity results in a wide performance spectrum and generates a high economic effect. The basis version of VEN BRUSH allows a selection of 2 unit positions to up to 5 unit positions. To be prepared for possibly changing requirements in your production process, you can also select the next larger variant and equip the free unit position as required at a later date. System examples for possible operating widths from 600 to 3,500 and operating lengths from 2,000 to 5,500 mm. Depending on your production requirements, you can individually select from: Short change times and high operating comfort are possible thanks to the quick-exchange brush system using a push-in system together with a coupling. The optional infinite angle setting of the round brushes permits impeccable edge processing. The use of the structured brush unit is intended for special surface processing. This brush is used to structurise furniture parts, hardwood and softwood, flooring boards or to provide an antique look of up to 1 mm deep at a throughfeed speed of 10 m/min. Where required, the VEN BRUSH can be extended by a dust removal system with rotating blow nozzles and ionisation system. Following a brushing or sanding/grinding effect, this complementary function ensures optimum workpiece cleanliness to meet high requirements. As an individual solution, VEN BRUSH convinces as a station in a Venjakob machine line or when integrated in an existing machine line. As such, control system configuration takes all interfaces into account, through to higher ranking control and monitoring. The high-performance system technology can be easily operated directly using a control panel or a touch panel.

Request for a quoteResults for

Touch panel - Import exportNumber of results

19 ProductsCompany type

Category

- Metallurgy - machinery and installations (4)

- Bending machine tools (3)

- Weighing and dosing equipment (3)

- Pipes and tubes - ferrous metal (2)

- Anti-glare screens, glass (1)

- Construction - Machines & Equipment (1)

- Glass (1)

- Measurement and control instruments (1)

- Potting equipment (1)

- Vibrators, industrial - installations (1)