- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tools

Results for

Tools - Import export

OTARA GMBH

Germany

Programmers, testers, tweezers, opening tools, ESD mats, screwdrivers, hygiene Mundex, etc.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Modern manufacturing faclilities using the latest in design and production technology ensure consistent, high quality, long life products that are competitive priced.

Request for a quote

XIMEA GMBH

Germany

XIMEA supports more than 30 of the most popular machine vision libraries, including Mathworks Matlab, MVTec HALCON, National Instruments LabVIEW, MicroManager, and OpenCV. The XIMEA CamTool is a cross-platform viewer application that is capable of setting most camera parameters, controlling various features, displaying the video stream, and saving snapshots and sequences. The feature set includes a histogram, line profile, LUT, averaging, flip/rotation, loop recording, shading correction, and more. For rapid prototyping, it is extendable with a scripting engine and custom plugins.

Request for a quote

BORNEMANN GMBH

Germany

The tool top (stamp) has an internal form, whose bottom part (matrix) has the corresponding opening (see image). These punch units are used in the areas of sheet shaping. Contact I have read and agree to the privacy policy. *Pflichtfelder

Request for a quote

BORNEMANN GMBH

Germany

We produce tool holders for rotating/milling centres to individual requirements – also in small series. The design is carried out in accordance with your drawings. Contact I have read and agree to the privacy policy. *Pflichtfelder

Request for a quote

IGUS® GMBH

Germany

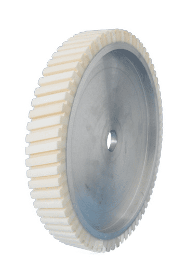

Easy rope tension For splitted drive wheel RL-ZA011-0250 Material: PA2200 / VA Prices upon request robolink® multi-axis joint robolink® Configurator DryLin® drive systems

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

High performance cartridges and heating elements are excellently suited to direct heating of all kinds of tools. Area, ring and barrel heaters are suitable for heating boilers and moulds, tools, die plates, machine parts and a range of other purposes. They can be manufactured individually to size, voltage and output specifically for your application. High performance cartridges are suitable for tool heating in the many different fields in which a specific compatible operating temperature is required. High performance cartridges are essential in the thermal machining process field. High surface loadings facilitate a correspondingly high performance in a small installation area, at operating temperatures of up to 750°C at the heating cartridge jacket. We produce diameters between 6 mm and 45 mm to order. Different types of feed also allow high performance cartridges to be matched to the relevant installation situation.

Request for a quote

BS BODENSTECKDOSEN SYSTEMTECHNIK GMBH

Germany

Height-adjustable floor tank 8908B with 8 slots. The housing is made of sendzimir galvanized sheet steel, the frame and lid are made of stainless steel. Floor coverings such as carpet, parquet, laminate etc. with a thickness of 15 mm can be used in the removable hinged lid. The lid, with two versions of cable outlets, closes even when the standard plugs are inserted in straight or angled form. Further equipment variants on request.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

On request, we can supply ball caster tables / ball transfer units tables adapted to your individual requirements. We usually use sheet metal panels, which are manufactured, edged and welded on all sides, in accordance with your size specifications. The standard table models are galvanised, but can also be supplied with powder-coated surfaces in different RAL colours, in bright steel or stainless steel. Ball caster spacing patterns are manufactured in accordance with your individual requirements. We supply every size of table. In the case of surfaces larger than 2,000×3,000 mm, several table plates are put together to make one table. The ball casters / ball transfer units are mounted by means of press fitting and are easily replaceable. They can be mounted in rows or positioned alternately.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Tool making & construction: The key to success We know the different industry-specific requirements for stamped parts and parts suppliers. Therefore, our day-to-day work includes very demanding tasks, which we overcome speedily and process reliably. Our spectrum of services for tool construction includes: 3D-CAD/CAM construction and programming (solid works, Peps, HSMworks) Wire-cut EDM (also contract manufacture) with workpiece sizes up to max. 600x400x350 mm Drilling erosion (start hole shooting) with workpiece sizes up to max. 250x350x300 mm Milling technology with workpiece sizes up to max. 650x500x500 mm Turning technology with workpiece sizes up to max. dm 210 x 1000 mm Flat grinding with workpiece sizes up to max. 600x300x375 mm and more…. Even complicated customer requirements are never a problem for us, but are instead a welcome challenge.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

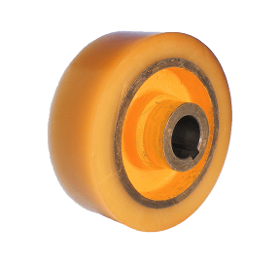

Rollers with a diameter of less than 75 mm are called contact rollers. They are equipped with a metal core flush on both sides and either covered with para rubber or Vulkollan®. The hardness of the coating is usually approx. 60º Shore, but other hardnesses are also possible. The coating of the contact rollers can, for example, be provided with grooves on request. Advantages Advantages of contact rollers FAPI-PA that have these coatings are: Wear resistance Oil resistance Fat resistance Emulsion resistance Ball bearings can also be easily integrated into the metal core from a roll width of 20 mm. Due to these outstanding flexible properties, Picard’s FAPI-PA contact rollers have proven themselves on the market for decades. Vulkollan® = registered trademark of the Covestro Group We will be happy to advise you in order to find a suitable contact role for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PA MILLED is the addition to the smooth model. At this type grooves will be milled in the rubber coating.The grooves can be milled into the coating in various widths, depths and angles. The total height of the covering can also be selected variably, with the standard height proven in practice being 20 mm. The higher the covering, the more elastic and therefore softer the contact disk surface appears. Due to the milled grooves, the contact disks are much more aggressive than smooth contact disks. The aggressive effect of the contact disk can be optimized for each application through an optimal ratio of groove and web width so that high-performance processes are possible. This contact disc also impresses with its longevity.The contact disks of the FAPI-PA series are exclusively provided with an NBR coating. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Uniformly wide polyurethane lamellae are attached in precisely established spacing while plastic foam lamellae are attached in the spaces between them to the aluminium hub of the frequency damped contact wheel FAPI-KS/V FREQUENCY DAMPED. The height of the coating resp. the length of the polyurethane and plastic foam lamellae can be varied depending on the application (standard: 25 mm). The positioning of the lamellae dampens the howling sounds in the upper frequency range in the contact wheel coating during grinding so that they are no longer audible to the human ear. The contact wheel FAPI-PUS/KS frequency damped achieves a significant reduction of the noise level in the workplace and so contributes its share to work safety. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VUS OPEN is a further development of the dense model. Here the aluminium core is coated alternately with a long and short lamellae of foamed up Vulkollan® . The overall height of the coating must also be adapted to the respective application and is therefore variable (standard: 35 mm). The open model cools better, or respectively it dissipate heat better. The precise adaptation of the soft running cushion to the workpiece makes it possible to achieve high performance results when finishing. Advantages The contact wheels of the FAPI-VUS – series are coated only with lamellae of foamed up Vulkollan® Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The expander rollers FAPI-VU-HAND are an optimal grinding tool for working with all types of abrasive sleeves. The expander rollers are exclusively equipped with a specially grooved coating of foamed Vulkollan®, whereby the abrasive sleeve is clamped by the centrifugal force during the machining process. The expander rolls coated with foamed Vulkollan® (VU) are often referred to in practice as “expander rolls with foam” or “abrasive sleeve carriers”. We would be pleased to advise you on which expander rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The expander discs FAPI-PA are an optimal grinding tool for working with all types of sanding sleeves. The expander discs are exclusively provided with a specially slotted NBR coating, which means that the sanding sleeve is tensioned by centrifugal force during the processing process. In practice, the expander discs coated with the material NBR are often simply called “rubber expander discs” or also grinding sleeve carriers.Advantages of expander discs with pararubber coating: - Wear resistance - Oil resistance - Grease resistance - Emulsion resistance We would be pleased to advise you on which expander rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

As the name indicates, the aluminium hub of the contact wheel FAPI-VU SMOOTH is coated with a coating of a smooth lamellae of foamed up Vulkollan®. The coating height can be varied depending on the application. Advantages The contact wheels of the FAPI-VU – series are only coated with a lamellae of foamed up Vulkollan®. Lamellae of foamed up Vulkollan® is cellular Vulkollan®, a polyurethane foamed with water which has very high dynamic properties. Lamellae of foamed up Vulkollan® can be identified by its slightly yellowish colour. Benefits of contact wheels coated with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VUS/KS is a version coated with lamellae of foamed up Vulkollan® and plastic foam lamellae. The overall height of the coating must also be selected based on the respective application. The alternating lamellae of foamed up Vulkollan® and plastic foam lamellae make the contact wheel especially soft and adaptable. In practice, this contact wheel is used mainly for the finishing of lightly cambered or rounded workpieces. The different material densities result in the heat generated during grinding being drawn off very effectively. Advantages The contact wheels of the FAPI-VUS – series are coated only with lamellae of foamed up Vulkollan® Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The FAPI–PA MILLED FREQUENCY DAMPED contact disc is the further development of the milled version. Grooves with a groove width-groove depth-web width ratio specially developed by us are milled into the NBR coating of the contact disk. This means that – during the belt grinding process – both the noise level is reduced to a minimum and the material removal rate is increased to a maximum. The total height of the covering can also be selected variably, with the standard height proven in practice being 20 mm. The higher the covering, the more elastic and therefore softer the contact disk surface appears. The contact disks are very aggressive when used due to the grooves they contain. The aggressiveness effect of the contact disk can also be optimized for each application with the milled frequency-damped contact disk by means of an individually optimized groove width-groove depth-web width ratio. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Gubisch rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core receiving hole is designed with a feather keyway. We would be pleased to advise you on which gubisch rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

Special tools: The greatest possible flexibility for individual custom-made products is a matter of course for us. According to your sketch, demand-oriented solutions are created that are precisely tailored to your requirements.

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

ENGRAVING TOOLS For engraving plastics and non-ferrous metals. The width must be ground by you, to suit your requirements.Engraving cutter and engraving stylus: For engraving plastics and non-ferrous metals. The ""typeface width"" must be sanded down in-house. Engraving cutter 60 °, point angle 60 °, number of teeth 1, spiral angle 30 ° r."

Request for a quote

BURRE HYDRAULIK GMBH

Germany

6-way construction With leakage control Media: hydraulic (flow line/return line), cooling liquid (flow line/return line), natural gas, oxygen

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

A wide variety of very individual construction options are made possible with Vulkollan® coated components. Connections between Vulkollan® and metal can be easily created after the metal component has been pretreated. During this pretreatment, the surface of the component is cleaned and degreased using a sandblasting process. An optimal bond is then guaranteed by applying an adhesion promoter. The metal component (e.g. steel, aluminum, cast) takes on the function of the stable supporting body. The Vulkollan® coating meets high-performance requirements in terms of wear protection, damping and noise reduction. We would be pleased to advise you on which metal compounds can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Harbs rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. We would be pleased to advise you on which harbs rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VU MILLED is the addition to the smooth model. This is accomplished by milling grooves into the coating of lamellae of foamed up Vulkollan®. The overall height of the coating is also adapted to the respective application and is therefore variable. The grooves can be cut into the coating in various widths, depths and angles. Due to the grooves inserted, contact discs with a milled design are significantly more aggressive than contact discs with a smooth design. The aggressiveness effect of the contact disk can be optimized for each application through an optimal groove width-groove depth-web width ratio so that high-performance processes are possible. With this contact disc, too, no signs of fatigue occur after long, intensive use if used properly.The contact discs of the FAPI-VU series are exclusively provided with a coating made of foamed Vulkollan®. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PUS/KS is an extremely soft version of a contact wheel with a polyurethane foam and plastic foam lamella coating. The overall height of the coating must also be selected based on the respective application. The alternating polyurethane and plastic foam lamellae make the contact wheel extremely soft and particularly adaptable. In practice, this contact wheel is used mainly for the finishing of strongly cambered or rounded workpieces. Because of the different material densities and the spacing between the lamellae heat dissipates very well during the grinding process. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PUS OPEN is a further development of the dense design. Here the aluminium core is coated alternately with a long and short polyurethane foam lamella. The overall height of the coating is also adaptable to the respective application and is therefore variable (standard: 35 mm). Because of the variant of the open design, the abrasive belt can better cool because the heat from the belt sanding process is better dissipated. Through the precise adaptation of the extremely soft running cushion to the workpiece that shoud be found it is possible to achieve high-performance results when finish grinding. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quoteResults for

Tools - Import exportNumber of results

126 ProductsCompany type

Category

- Cutting - machine tools (50)

- Industrial tools (34)

- Stowage - equipment and systems (10)

- Steel, tool (8)

- Foundries - copper, bronze and brass (7)

- Building hand tools, non-power (4)

- Gas and oil - exploitation (3)

- Electric tools (2)

- Precision engineering - portable power tools (2)

- Electronics - import-export (1)

- Stainless steels (1)

- Cameras, cinematographic (1)