- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- system maintenance

Results for

System maintenance - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Precision handling for heavy loads From end-of-line, through rack handling, to automated storage: Lödige has complete control of all the materials handling processes required in the press shop — including tool handling and systems for improved tool maintenance. Your advantages using Lödige solutions in the press shop: Ergonomic tool maintenance Coil handling up to 40 t Safe provision of pressed components Lifting and tilting tables up to 40 t Connection to pressed component storage Linked materials handling systems

Request for a quote

ROLLON GMBH

Germany

Versatile multi-axis system designed for feeding machine stations. The Y axis can be realized with a rack and pinion driving system for multiple independent carriages or with a short belt system for connected Z axes. The motion systems can be designed with recirculating ball guides or with bearings depending on loads, dynamics, and different environments. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Versatile transfer system for metal sheet handling, designed as the main element in a series of presses which eventually combine with load/unload systems. The system features high positioning precision with heavy duty cycles and high dynamics, and is also available for very extended lengths. It manages cantilever loads to keep one side of the series free for operations. The system is driven by a belt with Ω transmission. The Z axes can be placed at different distances, according to the loads. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

The ECO SYSTEM units are linear actuators made of a self-sustaining extruded aluminum frame and are driven by a polyurethane belt with AT metric profile steel inserts. Three different sizes available: 60mm, 80mm, 100mm Version available with recirculating ball bearing or roller rails Reduced weight ensured by the light frame and the aluminum sliders High sliding speed The ECO SYSTEM series actuators are offered with two motion systems: ECO SYSTEM – SP Featuring a maintenance free recirculating linear guide rail fitted inside the profile. ECO SYSTEM – CI Featuring four rollers with a Gothic arch outer profile sliding on hardened steel bars placed inside the profile. Main fields of application for Eco System linear units: Automation Packaging Industrial machinery

Request for a quote

IGUS® GMBH

Germany

Safe energy and data transmission The igus® Chainflex® cable range offers a choice of over 850 different cables, available from stock. A main focus of the range are the data and bus cables. Solutions based on copper, glass or plastic fiber optic cables are provided for almost all bus systems in industrial use. We continue to provide you with all supply cables for your drive systems such as motor cables with and without brake/tacho cables and the matching feed cables. Ready assembled with plugs and sockets on request. Cost-reducing assembly The use of pre-assembled E-ChainSystems® enables expensive assembly hours at the place of installation to be considerably reduced. Functionally tested systems guarantee that plant components are soon put into operation. Assembly service We would be pleased to send you an offer for complete solutions, including all assembly services. You do not tie up your own resources and you have a trouble-free energy supply system for the future at a fixed price. LBT FLIZZ® - High speeds and accelerations Travel distances up to 120m, travel speed up to 8 m/s Suitable for moving or stationary controls, ideal for all bus systems When light weight is required When quiet, maintenance-free operation is required When rust-proof property is required At -10°C to +60°C constant temperature At accelerations over 10 m/s² Energy supply system for all media, not only electrical Also suitable for outdoor use (with reduced load data) Your benefit from LBT FLIZZ® Guaranteed service life Cost-effective compared with conventional energy supply systems Cable protected against dirt, rain, sun, ice, snow and leaves Insensitive to wind and motion Good resistance to chemicals, solvents, etc. Use of special cables possible, e.g. servo drive cables, fiber optic cables, bus systems etc. almost maintenance free Quick and easy installation due to delivery as a ready-assembled system Easy integration with existing plants Cable length 50% of the travel distance No central cable junction No effort required to maintain carriages Sewage treatment plant Longitudinal scrapers Sand traps Rain water overflow reservoir Galvanizing equipment Cranes Plant construction Space-saving and compact energy supply with LBT FLIZZ® - low maintenance system, delivered pre-fitted with ready-assembled igus® E-Chain Energy supply system protected from wind and weathering. The used materials are weather-resistant, as well as resistant against most chemicals, oils, fats, coolants and solvents Solid plastic with powder-coated support tubes Modular assembly: the system can be enclosed with intermediate panels! Can be delivered pre-fitted Variable fields, which are simply screwed on top of each other Glide rail integrated in the profile

Request for a quote

IGUS® GMBH

Germany

Save 88% assembly time with cost-effective energy chain for intralogistics and crane systems. The igus autoglide 5 system transfers energy, data, fluids, and air safely in a single system, requires almost no maintenance, and is also very cost-effective, including a 2400.07AG.075.0 e-chain, steel cable guide, harnessed bus cable, and five single cores of 6mm² each.

Request for a quote

IGUS® GMBH

Germany

- Low-maintenance system for travel up to 100 m - Other sizes and versions available, travel up to 200 m and more with E2 roller e-chains® - Protection against weather and dirt exposure - Cost-effective and fully enclosed complete solution - Standardized and modular design - Simple wall assembly or optional floor mounting - Cable lengths up to 50% shorter than festooning, low-profile installation and no cable junction - Cables are at all times guided with a defined bending radius, and tensile forces are absorbed by the e-chain® - Cables cannot hook, jam, or tear - No slip ring contacts (as is the case on motor drums) -Cables or hoses can easily be retrofitted at any time Reduce electricity costs - direct drive due to scraper, no additional drives needed (as is the case on motor drums) Scraper arm (e.g. as mechanical connection to the scraper carriage) optionally available - we document the situation on-site and will propose a customised solution

Request for a quote

IGUS® GMBH

Germany

DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv DryLin® N - Technical data DryLin® linear guide systems in the cleanroom DryLin® N - Applications DryLin® N - Design rules System selection & service life calculation NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. DryLin® N - Low profile linear guide system NK-02-17 DryLin® N - Low profile linear guide system NK-22-17-40 drylin® N - Low profile linear guide system NK-22-17-30 NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor DryLin® N low profile guide systems offer you low profiles in various widths. Like in all drylin® products, the carriage runs without lubrication in anodized aluminum profiles. The material used and the unique design make DryLin® N a cost-efficient and flexible guide system. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Rail made of anodized aluminum 2 Gliding elements made of iglidur® J or J200 3 Carriage made of chromated zinc or plastic 4 Carriage with threaded hole or through hole Advantages: Small installation height between 6 and 12 mm Lightweight Numerous carriage options – also with pretension Maintenance-free, self lubricating Corrossion-resistant Low wear with low coefficient of friction Rails in silver or black anodized When not to use ? When precision below 50 μ is required In high loads over 50 kg drylin® T drylin® R drylin® W When high resistance to chemicals is required drylin® W drylin® R DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv Standard, preload and floating bearing NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. 1. NW-01-27 standard 01 with through hole g 2. NW-02-27 standard 02 with threaded hole 3. Preload with through-hole or threaded hole 4. uinjection-molded with through-hole or threaded hole 5. NW-21-27-60P Vollkunststoffschlitten mit Durchgangsbohrung 6. NW-22-27-60P solid polymer carriage with through hole 7. NW-11-27-80 double carriage with through hole NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 1. Standard 02 with threaded hole 2. Injection-molded with threaded hole 3. Standard 01 with through hole NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P 1. Standard 02 with mounting nuts 2. Injection-molded with mounting nuts NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

If the service is right, every production plant will work economically for many years. We offer you a qualified repair and maintenance service, even for older machines and third-party products. Our service technicians will look after you quickly and anywhere with fully equipped vehicles. We pay attention to the good training of our personnel. Experienced mechanics, locksmiths or electronics specialists offer you every support to ensure the perfect functioning of the delivered systems. Our plant service – also for older machines and other manufactures!

Request for a quote

HOPPECKE BATTERIEN GMBH & CO. KG

Germany

The grid | power V X battery is characterized by its special design as completely cast positive plates with lamellar structure. The use of high-purity grid lead with a high electrode thickness as well as a low acid density results in an expected design life of up to 25 years. It is particularly suitable for high-current discharges of short duration and thus predestined for use in power plants and switchgear. The product design according to DIN 40738 ensures the highest compatibility when replacing and expanding existing plants and battery systems. In combination with the HOPPECKE grid | AquaGen recombination system, maintenance costs can be reduced, and even maintenance-free operation can be achieved.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

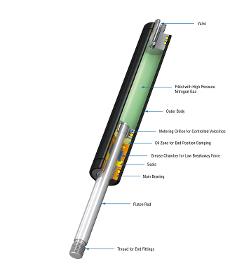

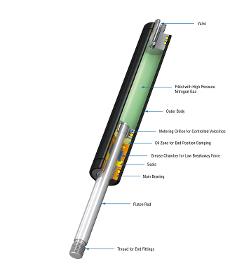

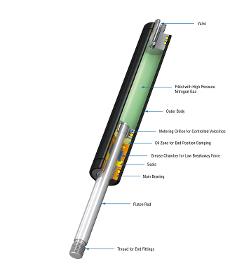

Valve Technology Force range max. 180 N Stroke 20 mm Universal and tailor made: ACE industrial gas push type springs of the NEWTONLINE family offer perfect support of muscle power with forces from 10 to 13,000 N with body diameter of 8 to 70 mm. With their high quality features the NEWTONLINE gas springs form the industry standard. These durable and sealed systems are ready for installation, maintenance-free and filled with pressurised nitrogen gas. They are supplied filled according to individual customer pressure requirements and maybe adjusted later by use of the inbuilt valve. The free of charge ACE calculation service designs the gas springs with mounting points specifically for the particular application. A variety of additional components makes assembly even easier and allows universal application of the gas springs.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Valve Technology Force range max. 100 N Stroke 20 mm Universal and tailor made: ACE industrial gas push type springs of the NEWTONLINE family offer perfect support of muscle power with forces from 10 to 13,000 N with body diameter of 8 to 70 mm. With their high quality features the NEWTONLINE gas springs form the industry standard. These durable and sealed systems are ready for installation, maintenance-free and filled with pressurised nitrogen gas. They are supplied filled according to individual customer pressure requirements and maybe adjusted later by use of the inbuilt valve. The free of charge ACE calculation service designs the gas springs with mounting points specifically for the particular application. A variety of additional components makes assembly even easier and allows universal application of the gas springs.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Valve Technology Force range max. 100 N Stroke 20 mm Universal and tailor made: ACE industrial gas push type springs of the NEWTONLINE family offer perfect support of muscle power with forces from 10 to 13,000 N with body diameter of 8 to 70 mm. With their high quality features the NEWTONLINE gas springs form the industry standard. These durable and sealed systems are ready for installation, maintenance-free and filled with pressurised nitrogen gas. They are supplied filled according to individual customer pressure requirements and maybe adjusted later by use of the inbuilt valve. The free of charge ACE calculation service designs the gas springs with mounting points specifically for the particular application. A variety of additional components makes assembly even easier and allows universal application of the gas springs.

Request for a quote

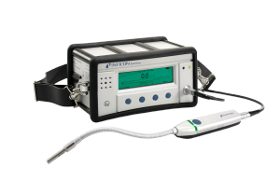

INFICON GMBH

Germany

The portable Extrima Leak Detector is the ultimate intrinsically safe instrument for leak detection in the toughest environments, including hazardous locations such as Zone 0 (corresponding to Division 1). The Extrima allows you to quickly find leaks on a wide range of industrial applications such as aircraft and hydrogen cooled generators. With the Extrima the aviation industry has a safe, accurate and yet simple solution for leak testing of complete fuel systems, both in production and maintenance situations. Thanks to its high sensitivity, the Extrima can detect even minute leaks with pinpoint accuracy. Extensive tests have shown that using the Extrima can reduce the average time by more than 50 % for identifying, locating and repairing a leak on a fighter jet during maintenance. Click here to see how easy it is to find leaks on aircraft fuel system using the Extrima (video 3:55, YouTube). It is certified for use in Zone 0, classification Ex ia, IIC T3 with ATEX, IECEx,...

Request for a quote

TROTEC GMBH

Germany

WATER SEPARATOR WA 4I MULTIQUBEWater separator WA 4i for combination with MultiQube insulation layer dryers The new WA 4i is provided with an integrated micro filter system with low-maintenance magnetic lock filter compartment to take in micro filter cartridges with a threefold filter element. This makes the WA 4i a versatile integral solution with all pre-HEPA filter stages in only one device. Advantage: improved flow-optimized filter technology, quicker setup, decreased material and space requirements – no separate additional micro filter housings required. With respect to insulation drying of surfaces sized up to 40 m², no other model is quite fit to hold a candle to this separator, for despite its ultra-compact dimensions the WA 4i comes fully equipped with numerous practice-oriented detailed solutions, such as a construction yet easier to maintain, TTKwic quick couplings, cable holder, residual water drainage and much more.

Request for a quote

HOPPECKE BATTERIEN GMBH & CO. KG

Germany

The trak | uplift impulse battery system offers decisive advantages over conventional lead-acid drive batteries. The high-current capability of the virtually emission-free AGM monobloc batteries ensures long runtimes in dynamic applications and short-term high loads. The integrated onboard charger provides even greater flexibility and availability. This is because the system can be temporarily charged at any standard socket. In conjunction with a HOPPECKE charger, up to 16% energy costs can be saved. Thanks to AMG technology, the system is completely maintenance-free, so there is no need to refill water over the entire service life. trak | uplift impulse is the perfect companion for truck-mounted forklifts and electric pallet trucks.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Discover the easy handling of our Pressure Transmitter and Reader of the PT-RF series. The PT-RF series of pressure transmitters are an alternative solution for universal pressure measurements for fluid technology applications, which will provide benefits for system operators, maintenance personnel and repair technicians as well as for original equipment manufacturers. The advantages resulting from the use of the new technology for system operators, maintenance personnel and repair technicians are clear: Measurements can be carried very easily, without extensive training and within a few seconds at the press of a button and then documented in a reliable process. Unscrewing and re-installing pressure gauges or other measuring and display devices – practically a temporary opening of the system – is not required. Potential hazards for people, machines and the environment, for example from emitted residual oil in the test hose or leaks at the measuring point, as well as ingress of...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

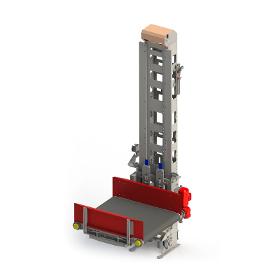

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Overcome heights, safely and precisely. With its precise and efficient lifting unit, the Vertical Transporting Unit performs a real show of strength – with ease! The belt conveyor element incorporated into the baggage lifter is raised and lowered precisely using a lifting unit with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. Between the two upper and lower end positions, any intermediate destinations can be reached. It is also possible to use the Vertical Sorting Unit in flight baggage systems with a container system. An appropriate Motion06 or FMH conveyor can be incorporated to work with the lifter. VTU – 420/660 Low Starting Height Low overall starting height possible. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Unique and light as a dragonfly – this is how the Motion06 Inclined Transport Unit works – quickly and safely overcoming any height difference. The inclined conveyor transports flight baggage directly to the passenger boarding bridge, meaning it can be used in direct proximity to the aircraft. Baggage or similar general cargo is either safely lifted onto the aircraft or lowered onto the apron. Staff must no longer carry the baggage up and down the sometimes wet or icy stairs in any weather. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive. Quick Installation Swift assembly due to a simple modular system, perfectly optimised for transportation. Efficient Energyefficient and economic design. UltraSimple Adjustment Ultrasimple adjustment to required installation conditions.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With a capacity of up to 2500 pieces of baggage per hour, strength and resilience are fundamental. The Motion06 Vertical Sorting Unit Belt Conveyor is used for the distribution and merging of baggage and general cargo between two or three levels. The belt conveyor incorporated into the Vertical Sorting Unit is height adjusting using a top of the line lifting system with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. It is also possible to use it in flight baggage systems with a container system. The belt conveyor is replaced by an appropriate conveyor element for this purpose. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

SHS PLUS GMBH

Germany

The plusMETER combines the functionality of a power monitoring system, a process data acquisition system as well as that of a process control system in a single device and can replace whole control cabinets because of its integrated load circuit. Acquisition of all energy carriers Don’t limit yourself to electrical energy – all energy flows in your facility can be acquired and plotted by one central device. Transparent production costs Keep an eye on your profit margin – automatically visualize production costs or communicate them to your ERP system. Remote maintenance Avoid engine downtimes by worldwide system access for problem analysis – for authorized personnel only, of course. Communication of events Stay up to date, define events and keep being informed automatically either by e-mail or directly per push message on your smartphone. Automatization of routine tasks Automate maintenance processes and more..

Request for a quote

HAVER NIAGARA GMBH

Germany

The T-CLASS is a completely overhauled supplement to the series of free-vibrating screening machines. The main principle of the machine’s concept is to implement individual customer wishes by employing proven, reliable and field-tested components as flexibly as possible. Depending on the profile of requirements, the T-CLASS is available in heavy duty design for regular and high loads. Through its modular design the T-CLASS offers the possibility of customisation in order to suit individual customer needs. The T-CLASS’s area of application encompasses a variety of industries with input material of 0 - 200 mm and cut sizes of 2 - 125 mm. Advantages modular design optimally suits individual job requirements available in imperial or metric system highly maintenance friendly extended lifetime through a reduction of welded connections bearing lubrication with grease or oil adjustable imbalance masses rapid exchange of screen cloths You’ll find detailed information in our product...

Request for a quoteResults for

System maintenance - Import exportNumber of results

23 Products