- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- surface treatment

Results for

Surface treatment - Import export

J.D. GECK GMBH

Germany

Use our industrial manufacturing expertise for your products too Electroplated surface finishing The maximum goods window for galvanising, chromeplating and nickelplating is L / W / D 2800x450x1000 mm. Chrome and nickel plating Galvanising (galvanising without passivation; blue galvanising with variable layer thickness and blue passivation; thicklayer passivation with nanosealing) Electrostatic powder coating Maximum load per hook 30 kg workpieces up to 60 kg Maximum workpiece size L / W / H = 3000/800 /1700 mm More information available at https//www.geck.de

Request for a quote

JOSEF JASPER GMBH & CO. KG

Germany

All products manufactured by us can be equipped with the appropriate corrosion protection according to your wishes and specifications. Epoxy resin coatings Hotspray coatings Hard and soft rubber linings KTL or powder coatings ECTFE/Halar SÄKAPHEN® coatings Pickling and passivation for stainlesssteel applications For drinking water systems, we can of course also provide coating products approved by KTW and DVGW w120

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used in auto, which is very strict in tolerances and surface treatment. The surface treatment is black chrome plating,the surface is required to be flawless.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Precision machinery parts,Brass turning and milling.Electric zinc surface treatment

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts used for the precision machinery parts,made by brass and no surface treatment.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

They are the accessories used in electronic panel control,after processing for a variety of color surface treatment.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in machine support.Made by aluminium, machining and doing the sandblasting and natural anodize surface treatment.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts made by aluminum, which was machining by CNC milling machine,there is no surface treatment.

Request for a quote

ROLLON GMBH

Germany

International patent registered for the CLEAN ROOM SYSTEM line (DIN EN ISO 14644-1) The CLEAN ROOM SYSTEM units are linear actuators with belt driven transmission and are specifically designed for Clean Room applications They are supplied with a certificate issued by the IPA Fraunhofer Institute in Stuttgard, which certifies compliance with class ISO 3 (DIN EN ISO 14644-1), or with class Fed Std 0.01 (FED 209 E). The system prevents particles from being discharged in the environment where the linear unit is located. This has been achieved by using a special straight seal that closes the horizontal opening where the slider moves, as well as by the operation of a 0.8 vacuum pump connected to 2 vacuum pipes located inside the drive head and the idle head. The system allows vacuum to be generated inside the unit so that any particles released when the system is operating are sucked towards the air filtration areas. Clean Room System linear actuators components are all made of...

Request for a quote

KAMAT GMBH & CO. KG

Germany

We have specially developed the KAMAT Gekko 350 in order to clean large steel surfaces, for example ships, or large tanks, rapidly and without building scaffolding. Key technical advantages of the high-pressure surface cleaner are the thought-out combination of natural magnets and chain drive, as well as controllable high-pressure nozzles. The complete high-pressure system is remotely controlled conveniently and safely.

Request for a quote

KAMAT GMBH & CO. KG

Germany

Our Surface Cleaner 3000 air is an extremely powerful high pressure cleaner. It is capable of cleaning at pressures of up to 3,000 bar. To make it even more efficient and smooth in operation, we have fitted it with pneumatically driven rotating nozzles. This ensures an even cleaning process at all times. A common application for our hp floor cleaner is the removal of rubber residue from airport runways. All our surface cleaners can be fitted with a vacuum. This ensures a trouble-free and dirt-free working environment, improves visibility and workplace safety and reduces the impact of the process on the environment.

Request for a quote

KAMAT GMBH & CO. KG

Germany

High-pressure cleaning and surface preparation with water requires precise management of the water jet. This precise management is necessary to ensure that the required result (e.g. surface finish) is achieved within a reasonable time. The method must be safe and fatigue free. With this in mind, we offer a specially designed and manufactured range of high pressure guns with electrical or mechanical control. The exceptional ergonomics of these tools have been achieved through innovative detail solutions: For example, our high-pressure guns are equipped with a special swivel handle that transmits any torque to the wrist. In addition, the hose connection can be swivelled in all directions, allowing optimum hose routing for all working situations. Our range of high pressure guns is complemented by various versions of foot valves, rotating gun lances, rotating nozzles and other accessories for a wide variety of applications, such as pipe cleaning.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Impregnation systems to close micropores in metal castings as well as in copper, aluminium or magnesium alloy castings. The parts to be impregnated are fixed in baskets. The latter are transported by a special crane system as well as with reservoir roller conveyors. Excess material is removed by centrifuging of the baskets. The impregnating agent remaining in the pores in fluid form is hardened by heating in a hot water bath. The process sequence runs fully automatically under a microprocessor control.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Sustainability is very important to us, so we buy back existing plants, upgrade and adapt them to customer needs Siempelkamp machines and plants go through a sustainable life cycle We buy back machines and entire plants that were in operation and adapt them to the individual needs of our customers. We modernize used plants and upgrade them to current industry-standards with increased performance. Siempelkamp offers you a wide range of pre-owned machines and plants When purchasing a plant that has been in operation, professional and cost-effective implementation of all measures - from dismantling to commissioning - are decisive processes for project success. We offer you second-hand plants for the production of particleboard, MDF and OSB with continuous press systems from well-known brands such as Siempelkamp, Küster, Bison, and Metso.

Request for a quote

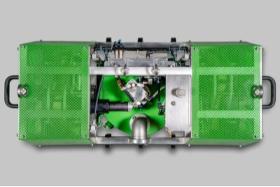

WALTHER TROWAL GMBH&CO.KG

Germany

THE EFFICIENT SOLUTION FOR SMALL PRODUCTION SERIESAre you looking for a solution that is a more economical choice than a larger Trowal system? Then look no further than our E5 mini barrel. It is perfect for deburring and abrasion, above all on small workpieces from the optical and fine mechanics industries. The double-conically shaped rotating barrel body generates an intense rotation to achieve the perfect abrasion result. SOPHISTICATED TECHNOLOGY The mini barrel stands on a steel sheet construction with four pedestals. The barrel bodies are secured to a drive roller and support roller with locking rings. The barrel body is made from polyurethane and the quick-action cap is waterproof. SPECIAL EQUIPMENT It is also possible to attach two additional barrel bodies if necessary. These are driven via a roller system that is fully variable thanks to a three-phase motor. The cover can also be ordered with safety switches.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

Mass coating of small parts using the hot drum process Coating with the Rotamat is the economical solution for the surface finishing of mass-produced small parts made of elastomers, metal or wood - for example, O-rings, handles, springs or screws. Even geometrically complicated or particularly sensitive parts leave the machine perfectly coated and dry. The coating process is fully automatic, so that the time-consuming insertion or suspension of the parts on racks - which is necessary with conventional automatic coating machines - is no longer necessary. The Rotamat is suitable for a wide variety of coating agents. Typical applications are: — Decorative coating — Bonded coating — Adhesive coating — Anti-corrosion coating — Insulation coating

Request for a quote

W&K METALLVERARBEITUNG GMBH

Germany

In addition to laser cutting, edging and welding, we at W & K Metallverarbeitung also offer various services in the field of post-processing and surface treatment either internally or through reliable external partners. We execute all requirements according to your required factory standard. Would you like a final assembly of your products? This is also possible with us. For coating and surface treatment, we work together with high-performance partners. • Powder coating (maximum component size 1.6 x 3.0 x 8.0m (W / H / L)) Galvanized galvanizing (blue, yellow or black chromating, max. Length of the component 3,000 mm) • Hot dip galvanizing (spin-galvanizing, high-temperature galvanizing, maximum component length 9,000 mm) • KTL coating • rays Which surface do you want? We are happy to help!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

Our model "Super-Glasmatic" is particularly characterized by a compact, Compact design, simple operation, low material consumption, optimum use of space, highly effective dedusting, rational workmanship, environmentally friendly operation without dust pollution and adjustable material consumption. Housing with 2 mm steel plate, with complete blasting agent recovery, with drain cup for quickest change of blasting agent, with interior lighting of the blasting chamber, with brush slots at the front, approx. 600 mm long for optimum processing of the glass objects, with 3 brush slots on the side and at the top for problem-free penetration of the parts to be irradiated, With sliding blades at the sides for dust-tight closing of the booth during the blasting process, with standard beam head and spray gun with hand lever, with all necessary compressed air and blasting hoses, with large plexiglass door (750 x 400 mm) for optimum visibility Filter system (residual emission <5 mg / m³).

Request for a quoteResults for

Surface treatment - Import exportNumber of results

19 ProductsCompany type

Category

- Surface treatment - machinery and equipment (3)

- Steels and metals - surface treatment and coating (2)

- Industrial sprayers for surface treatment (2)

- Sandblasting equipment (2)

- Mechanical surface treatment - machinery (1)

- Cleaning and maintenance - equipment and supplies (1)

- Alarms - security devices (1)

- Automobiles (1)

- Construction - Machines & Equipment (1)

- Couplings, mechanical (1)

- High-pressure cleaning machines (1)

- Internal transport systems (1)

- Precision measuring instruments (1)

- Radiators, engine (1)

- Tanks, metal (1)