- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- surface coating

Results for

Surface coating - Import export

SCHULZ STANZTECHNIK GMBH

Germany

Stamped parts / contract manufacture Your products delivered punctually As a flexible stamping business, Schulz Stanztechnik manufactures various stamped and stamped bent parts for the most diverse areas of application from conveyance technology components, the automotive industry to mechanical components such as washers and angle connectors or entire assemblies. We place particular emphasis on high-quality and punctual manufacture and delivery of the ordered products and services. We are also in a position to meet special requests of our customers at short notice. Alongside the actual stamping process, Schulz Stanztechnik carries out numerous additional tasks, such as the creation of threads, use of installation parts or the installation of several components to the stamped parts. These activities can be carried out during stamping as well as in a separate work process.

Request for a quote

J.D. GECK GMBH

Germany

Use our industrial manufacturing expertise for your products too Electroplated surface finishing The maximum goods window for galvanising, chromeplating and nickelplating is L / W / D 2800x450x1000 mm. Chrome and nickel plating Galvanising (galvanising without passivation; blue galvanising with variable layer thickness and blue passivation; thicklayer passivation with nanosealing) Electrostatic powder coating Maximum load per hook 30 kg workpieces up to 60 kg Maximum workpiece size L / W / H = 3000/800 /1700 mm More information available at https//www.geck.de

Request for a quote![Powerflex [p1] Und [p2]](/filestore/vig280/opt/product/3b/be/secutex_Lifitng_Powerflex-coating-P1_001_70d8714e.jpg)

SPANSET SECUTEX GMBH

Germany

This very compact thin layer surrounds the lifting strap either on a single side or completely. It is extremely wearresistant and ideal for very rough surfaces. The Powerflex coating provides additional protection to the textile against dirt and the penetration of foreign particles.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Material Schulz Stanztechnik manufacturers these axial ball bearings using the materials suited to the specific application. For the housing, steel, brass or stainless steel are used; for rings, steel or stainless steel which is always hardened. The balls are made of chrome or stainless steel, which is also always hardened. All material combinations – depending on their conditions of use – are possible for the assembly of the individual parts. Various surface coats for the individual parts can be supplied as well as finished bearings: brass which is uncoated or nickel plated; steel and stainless steel which is uncoated, zinc plated or nickel plated. All bearings are available lubricated or unlubricated. Structure DLG100 axial ball bearings consist of sheet metal housing, two hardened rings as well as hardened precision balls. Due to their structure, we refer to them as an encapsulated, full ball design.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

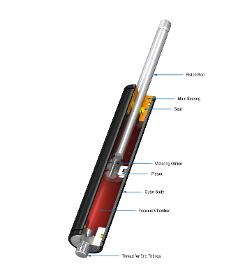

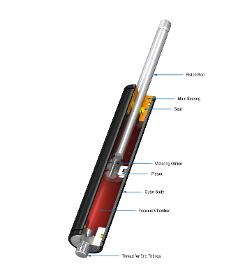

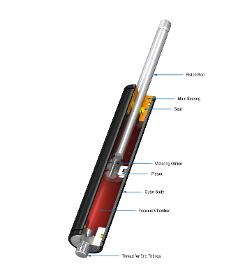

Adjustable Compression Force max. 1,800 N Stroke 50 mm High quality and long service life: The HB model of hydraulic damper can also be used as single or double acting brake. Its coated body in a slim gas spring design and the piston rods with wear-resistant surface coating are features of high quality and long service life. The maintenance free, ready-to-install and closed systems provide a constant feed rate and are adjustable, and the control segment on the piston makes adjustment at the end position child’s play. Thanks to many add-on components the assembly is easy to mount, so that the damper can be universally deployed for damping back and forth swinging masses, such as in power or free conveyors.

Request for a quote

DRESSLER GROUP

Germany

DG Mixing process which under the application of high speeds injects enough energy into a powder quantity to create a stable compound from different types of powders and grain particles. Used, for example, for coating surfaces of one type of particle with other particles.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We offer a wide range of high quality spring contacts or battery charging contacts. In our online catalog you will find over 300 standard spring contacts and connectors, which you can request directly from us with just a few clicks. https://katalog.nh-technology.de/ Completely custom designs or changes to specific specifications can also be made by us, including current rating, spring force, and plating. Our experienced team of engineers will help them design custom solutions that are perfectly tailored to your requirements. In doing so, we offer a variety of options, including different materials, surface coatings and connector configurations.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Four new models for even more flexibility The product family of aluminium Solid Clamp tube connectors has a new addition: size 30 base clamps, sleeve clamps and hinge clamps are now also available for delivery with integrated ball joint. A sleeve clamp with double ball also adds to the range. The ball joints are designed for loads of up to 40 Nm (static). Connected applications can be pivoted freely by 60° and rotated freely by 360°. This way, the new tube connectors with ball joint provide a significantly higher degree of freedom for construction than conventional hinged connectors. An appropriate surface coating on the ball joint makes for a high-strength clamping connection. The clamps feature a universal connecting plate for flexible integration. Features: can be combined with size 30 tube connectors the clamps feature a universal connecting plate (KGFS 30, KGM 30, KGGPZ 30) for flexible integration high-strength clamping thanks to special finishes

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Adjustable Compression Force max. 800 N Stroke 25 mm High quality and long service life: The HB model of hydraulic damper can also be used as single or double acting brake. Its coated body in a slim gas spring design and the piston rods with wear-resistant surface coating are features of high quality and long service life. The maintenance free, ready-to-install and closed systems provide a constant feed rate and are adjustable, and the control segment on the piston makes adjustment at the end position child’s play. Thanks to many add-on components the assembly is easy to mount, so that the damper can be universally deployed for damping back and forth swinging masses, such as in power or free conveyors.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Adjustable Compression Force max. 180 N Stroke 10 mm High quality and long service life: The HB model of hydraulic damper can also be used as single or double acting brake. Its coated body in a slim gas spring design and the piston rods with wear-resistant surface coating are features of high quality and long service life. The maintenance free, ready-to-install and closed systems provide a constant feed rate and are adjustable, and the control segment on the piston makes adjustment at the end position child’s play. Thanks to many add-on components the assembly is easy to mount, so that the damper can be universally deployed for damping back and forth swinging masses, such as in power or free conveyors.

Request for a quote

VOM HOFE KALTSTAUCHDRAHT GMBH

Germany

One of our specialities is the "phosphated and hot-coated" surface for the best possible cold forming. With this surface coating, our customers achieve above-average results in terms of mouldability and tool life.

Request for a quote

KAMAT GMBH & CO. KG

Germany

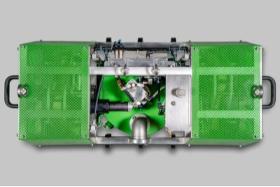

We have specially developed the KAMAT Gekko 350 in order to clean large steel surfaces, for example ships, or large tanks, rapidly and without building scaffolding. Key technical advantages of the high-pressure surface cleaner are the thought-out combination of natural magnets and chain drive, as well as controllable high-pressure nozzles. The complete high-pressure system is remotely controlled conveniently and safely.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The classic application of industrial robots. The application of wet paint is one of the classic uses of industrial robots. As a specialist for surface coating systems, Rippert naturally offers the full range of solutions in the Ex and non-Ex area. Robots and application technology are integrated into the overall system in relation to the specific customer and his application. Modern software concepts ensure economically optimum operation.

Request for a quote

STRONG MAGNETS GMBH

Germany

The corrosion resistance of Neodymium magnet is considered poor, surface coating is highly recommended for Neodymium magnets. With the expansion of elevators, wind turbines and permanent motors application, the users need higher requirement on corrosion resistance of Neodymium magnet, as the glue cohesiveness of unplated magnet is much better than plated magnets, also unplated products are better in the security. Now, more and more customers tend to use unplated magnets, upon this condition we have developed ultralow weight loss magnets after the continuous innovation and study. Normally, the weight loss test is over 150mg/cm² in the industry of Neodymium magnet, this will be different for magnets produced from different material formulation and manufacturing process. A lot of our new magnets can reach to 1mg/cm², (Testing condition HAST standard for 168hrs), due to its very low weight loss, the corrosion resistance is excellent

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Solutions for the transport and handling of parts. The question of how surface coating plants can be optimally integrated into a production environment arises with ever increasing frequency. Rippert offers its customer an ‘everything from one source solution’ here. The company’s own engineers develop coordinated solutions for the transport and handling of parts together with the customer. Simulation is thereby often the right tool for recognising the full potential of these possibilities. From frying pans to heavy workpieces from the wind power sector, Rippert has already ‘taken it all in hand’. We work on concepts in which industrial robots substitute or supplement the classic conveying equipment in coating plants. For handling tasks we often see the necessity for systems that work adaptively; this means that, for example, image processing systems must recognise the accurate position of parts in two and even three-dimensions so that a robot can pick up inaccurately positioned parts.

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

The requirements: long life good thermal capacity of silicones non-stick top coatings precise tolerances for runout, diameter and coating thicknesses without surface grinding

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

Mass coating of small parts using the hot drum process Coating with the Rotamat is the economical solution for the surface finishing of mass-produced small parts made of elastomers, metal or wood - for example, O-rings, handles, springs or screws. Even geometrically complicated or particularly sensitive parts leave the machine perfectly coated and dry. The coating process is fully automatic, so that the time-consuming insertion or suspension of the parts on racks - which is necessary with conventional automatic coating machines - is no longer necessary. The Rotamat is suitable for a wide variety of coating agents. Typical applications are: — Decorative coating — Bonded coating — Adhesive coating — Anti-corrosion coating — Insulation coating

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SANHA GMBH & CO. KG

Germany

SANHA®-Heat Distribution cabinet, surface-mounted, galvanically zinc-coated steel sheet, painted white (RAL 9010), with removable door and locking bolt, installation depth 125 mm.

Request for a quote

W&K METALLVERARBEITUNG GMBH

Germany

In addition to laser cutting, edging and welding, we at W & K Metallverarbeitung also offer various services in the field of post-processing and surface treatment either internally or through reliable external partners. We execute all requirements according to your required factory standard. Would you like a final assembly of your products? This is also possible with us. For coating and surface treatment, we work together with high-performance partners. • Powder coating (maximum component size 1.6 x 3.0 x 8.0m (W / H / L)) Galvanized galvanizing (blue, yellow or black chromating, max. Length of the component 3,000 mm) • Hot dip galvanizing (spin-galvanizing, high-temperature galvanizing, maximum component length 9,000 mm) • KTL coating • rays Which surface do you want? We are happy to help!

Request for a quoteResults for

Surface coating - Import exportNumber of results

20 ProductsCompany type

Category

- Steels and metals - surface treatment and coating (2)

- Surface treatment - machinery and equipment (1)

- Bearings, ball (1)

- Connectors, electronic (1)

- Heating, domestic - installations and equipment (1)

- High-pressure cleaning machines (1)

- Industrial sprayers for surface treatment (1)

- Laser - cutting and welding machines (1)

- Magnets (1)

- Plastic material processing (1)

- Stamping - steels and metals (1)

- Stapling and nailing - machinery and equipment (1)

- Steel & Metals (1)

- Straps, woven - industrial (1)