- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steaming

Results for

Steaming - Import export

KLÖPPER-THERM GMBH & CO. KG

Germany

The compact steam superheaters of type series PVN reach high steam temperatures even at low process pressure. Due to the compact design and control concept, they are characterised by short response times, high control precision, and high availability (existing redundancies). In many cases, our steam superheaters are designed as a "stand alone" system and provided completely assembled with all necessary safety devices and controls. The customer must only provide the process connection and the electrical connection.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

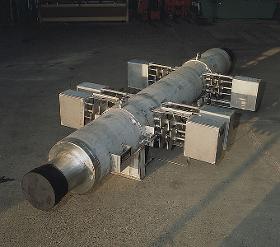

Cable Type Heaters have initially been developed and used for the safe operation in fertilizer plants. However nowadays, they cover a large range of applications due to their modular construction and minimum space requirements. They are suitable for heating up nearly all gases and liquids or superheating steam. They are mainly used in hazardous areas. Especially when processes require a combination of high power (in the MW range) high pressure and temperatures of up to 550°C cable type heaters are the means to choose.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Sunlight can also be channeled and focused to heat water, which can drive steam turbines in large-scale power plants. This Concentrated Solar Power (CSP) was once dominated by glass mirrors due to their unmatched reflectivity. Recent advances in aluminum reflectivity and brightness, partially due to our processing innovations, however, have made the material an effective substitute. Compared to glass, aluminum solar panels offer significantly lighter weight and better ratio performance versus cost.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

This inline thermocouple is especially invented for using under humid conditions. Compared with normal wire production this wire isolation is made in one work process, both conductors get moulded in Teflon at the same time. With this wire the measurement equipment is protected from capillary rising moisture through the wire. gas-, steam- and watertight Temperature range: -75°C to +250 °C, short-duration to + 300 °C Wire type: Teflon,0.38 mm, solid, Tmax: +300 °C

Request for a quote

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

The combination of a steam protector and a collecting tray is a valuable addition to any eye-level dishwasher. The steam protection strip shields the unit carcase against the steam escaping from the dishwasher when the appliance door is opened. The collecting tray fits flush with the carcase sides so that any dirt or condensation water underneath the dishwasher can be collected. Fitting is carried out without any additional tools using double-sided sticky tape.

Request for a quote

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

The combination of a steam protector and a collecting tray is a valuable addition to any eye-level dishwasher. The steam protection strip shields the unit carcase against the steam escaping from the dishwasher when the appliance door is opened. The collecting tray fits flush with the carcase sides so that any dirt or condensation water underneath the dishwasher can be collected. Fitting is carried out without any additional tools using double-sided sticky tape.

Request for a quote

KELVION HOLDING GMBH

Germany

Optimization of the global efficiency of a power plant based on the Rankine Cycle, requires the incorporation of highly specialized equipment that supports the maximization of the efficiency of the steam cycle, reducing the primary energy consumption, minimizing the environmental impact and helping to optimize the OPEX and consequently the return on the investment. The highly increasing competitiveness among the different centralized electricity generation technologies and the increasing concern on environmental issues, force all the available generation technologies to improve their efficiencies, reducing the primary energy consumption.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Ultrasonic flowmeter for high temperature gas and steam As the OPTISONIC 8300 provides a large measurement range and does not require recalibration, the installation can be simplified and costs reduced. For example since the flow sensor does not need to be removed, shut off valves and a bypass are not required. Also thanks to the large measurement range, a dual range measurement setup is not required. Traditional steam measurement solutions need continuous attention and recalibration to guarantee proper operation. As the diagnostics of the OPTISONIC 8300 enables it to look after itself, it does not require any attention. Even periodically recalibration is not required since the OPTISONIC 8300 provides excellent long term stability. Periodical verification of the proper functioning of the device can easily be done using the diagnostics as required.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

For the construction of its steam generators, Büttner uses the experience in steam boiler construction established at the end of the 19th century and combines this with modern technology, guaranteeing safe and protable facility operations Key features: Indirect steam generation with thermal oil Direct steam generation with ue gas from biomass combustion Debrators or reners, wax smelters, sifters and heating for buildings are just some of the applications for steam generators. Design, construction, assembly and inspection of steam generators in compliance with EN, ASME or GOST norms

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

Our steam generators are available on request as a ready-to-operate steam boiler plant: CERTUSS steam generator plus CERTUSS supply unit CVE. All components for the water supply and water conditioning of the CERTUSS steam generator are included in the complete steam plant. - Feed water tank - Desalination heat exchanger - Water softening equipment - Test extraction cooler - Mixing heat exchanger - Measuring equipment - Steam dryer The CVE supply unit is compatible with all the CERTUSS steam generators. In addition to the CERTUSS supply unit as a ready-to-operate boiler house installation on a basic frame, we also offer a complete container installation on request. Depending on the desired steam output a multiple steam boiler plant may be suitable for you.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

With the new EMX model range of electric steam boilers, CERTUSS offers you twice the steam output as before with a significantly smaller footprint. Electric steam generators from CERTUSS are heated by stainless steel heating rods with a large heating surface. The output of the heating elements is regulated continuously via semiconductor contactors. One energy-efficient advantage is the immediate modulating output adjustment to the actual steam demand during the operating cycle. For greater steam demand of up to 640 kg/h or fluctuating steam loads, several ELECTRO steam generators can be cascaded in series. Multiple systems like this are an especially economical solution. Our compact electric steam systems feature built-in feed water tanks and feed water pumps. They require very little space and have a short heat-up time. Steam systems are also available as a unit with water conditioning equipment installed at the factory.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

The electrical steam generators E 100 M – 120 M from CERTUSS offer you impressive output in two output capacities of 100 - 120 kW heat output. They are compact, economical and have a high output. All electrical versions do not require a permit for installation and use in Germany. Heating: Electrical heating rods Steam output 135 – 160 kg/h The sizes: E 100 and E 120 - In two output capacities of 100 - 120 kW heat output. - Fully electronic pressure and output control. - Compact stainless steel heating rod with low heating surface load, placed laterally on the pressure body for easy access. - Constant network load without consumption peaks. - Integrated multifunction display. - Multilanguage plain text indication.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

The new generation of a proven series. The CERTUSS Universal 500 - 1800 TC steam generators are characterized by the immediate modulating output adjustment and the simplified operation. TC is the abbreviation for Touch Control. CERTUSS steam generators of the Universal series with oil, natural-gas or combination combustion are manufactured in four sizes. Individually or combined they meet all requirements and dispose of lightened official installation conditions in Germany. Combustion: Oil, gas or a combination Steam output optionally 500 - 600 kg/h 700 - 850 kg/h 1,000 - 1,300 kg/h 1,500 - 1,800 kg/h

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

A multiple steam boiler plant from CERTUSS consists of several steam boilers connected in series plus the CVE supply unit. With a multiple steam boiler plant from CERTUSS you profit from a highly flexible steam supply through cascading. The CERTUSS steam generators interconnected in a steam system act respectively as the lead boiler for the base load or as the standby boiler for peak load periods. For steam outputs of up to 10,000 kg/h - High steam requirements are covered with a multiple steam boiler plant. Whether 2, 3, 4 or more combined boilers depends completely on your requirements for the steam supply. - The displays are effected on the touch screen of a selected steam generator. They can be called up at allocated workstations with all the operating functions.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

You require a mobile steam plant or you want to install a steam plant outside your plant building? Then the complete installation within a container is the ideal solution for you. The container steam plant contains all the required components – from the water treatment plant through to the steam trap. - CERTUSS steam generator - CERTUSS CVE supply unit - Feed water treatment - Steam distributor - Pressure reducer station - Clarification valve - Steam dryer - Condensate elevating system - Steam trap - Interior lighting of the container - Insulated pipe installation in the container - Emergency-off switch - Steel door or uPVC door - High-quality stainless steel wall with insulation - Outside coating as required The installation and commissioning of the container plant at the customer is on request either carried out completely or only partially (if an external installation company is used) by our customer service.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

The small steam boilers of the Junior 80 - 400 TC series are completely equipped, ready-to-operate, electronically controlled rapid steam generators with all safety devices for burner technology, pressure and temperature. With a height of only 1.5 m and 0.7 m width the Junior 80 TC steam boiler can be erected even in small spaces. Combustion: Oil or gas Steam output optionally 80 - 120 kg/h 150 - 200 kg/h 250 - 400 kg/h

Request for a quoteResults for

Steaming - Import exportNumber of results

20 ProductsCompany type

Category