- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- silicon ores

Results for

Silicon ores - Import export

J.D. GECK GMBH

Germany

Use our industrial manufacturing expertise for your products too ,Manufacture of silicone or aluminium moulds ,Gas internal pressure procedure (GIP) Processing of sheet plastic (cutting, milling, bending) More information available at https//www.geck.de

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

unprecedented opportunities thanks to newest 3D-print technology: whether ultra-stable up to 103°C/217,4°F heat-resistant plastic parts or elastical silicone up to 65 shore – we can meet your very special needs on a wide range – with a print resolution of up to 15 μm! Realizing ideas quickly: we print your prototypes, devices, models, sales samples, artworks or even final products made of plastics or silicone. For your individual 3d-print, we need your data-model in STEP- or STL-format. We are looking forward to your inquiries!

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

We seal your housings, control cabinets or lighting units, apply adhesives or cast electronic components. In addition to the proven, high-performance 2-component PUR seals (FIPFG), we cover other important areas of application for our customers by applying homogeneous 1-component seals. For example, if your application requires higher temperature and/or chemical resistance or may be less compressible than a foamed seal. Our one-component, elastic solutions are also used for electrically conductive seals. We dose silicones, polyurethanes or MS polymers in liquid, unreacted form directly onto your component. True to contour on the smallest geometries, extremely adhesive and durable. Perfect sealing – sealing, gluing, casting directly on the component. Absolutely true to the contour and directly onto your component. We enable our customers to do this in series thanks to state-of-the-art dosing systems.

Request for a quote

FRIEDR. FREEK GMBH

Germany

We can offer flexible heating elements manufactured from three different insulation materials: silicone, polyimide (Kapton) or polyester. Each of these materials possess different properties which make them suitable for diverse applications. Silicone heaters can also be produced in very large sizes, whereas polyimide is significantly thinner and polyester unbeatable in price when it comes to high quantities. All three of them are bespoke products made according to your needs, so within the bounds of what is technically feasible you as the customer can determine almost every feature of your heater. This can include; voltage, wattage, dimensions, shape, sensors, leads, plus much more. Due to their low thermal mass flexible polymer insulated heaters distinguish themselves by a very short response time and excellent controllability.

Request for a quote

FRIEDR. FREEK GMBH

Germany

In general, a Kapton film heater is always more expensive than a silicone heater or polyester heater. Where chemical resistance or the weight of the flexible heating element plays an important role, however, Kapton heaters are the ideal solution. The resistance of Kapton Polyimide to fungi, bacteria, ozone, weather, ageing and most chemicals, acids and solvents is very good, so that heating elements made of Polyimide (Kapton) are an ideal solution for many critical applications. Kapton foil heaters are also silicone-free and are characterised by an even heat distribution. The dielectric strength of a Polyimide film is very high and so the flexible Kapton (Polyimide) heater can be very thin. Due to the small thickness, the heat transfer to the component is improved and higher surface loads are possible. Typical applications for Kapton film heaters are: Laboratory technology, aircraft electronics, printers, diagnostic instruments, vacuum chambers, medical equipment and many more.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KROHNE MESSTECHNIK GMBH

Germany

Cable RTD sensor for plug-in The cable RTD sensors of the TRA-W series are constructed differently and adapted to typical operating conditions. The most important differentiating factor of the cable assemblies is their process connection, the operating temperature range and the insulation material of the connecting cable. Process connection: insertion, fittings: M8, 1/8", 1/4" and 1/2" Execution: insertion variant Temperatur range: -50 … +200°C Material: 1.4404 / AISI 316 L Sheath - Ø: 3, 6 and 8 mm Cable material: PVC, Silicon or Teflon IP protection class: 54

Request for a quote

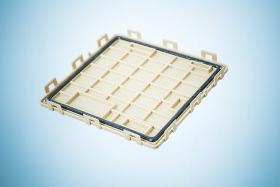

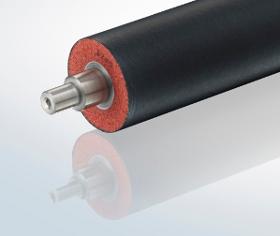

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

KB RollerTech processes seamless metal belts (stainless steel and nickel). Compared to coated plastic belts, metal belts offer the following advantages: very high thermal conductivity very high physical stability Today, KB RollerTech processes metal belts with the following properties: Properties Nickel belts Stainless steel belts Length < 350 mm < 400 mm Diameter 15 - 50 mm 10 - 100 mm Wall thickness 30 - 500 µm 35 - 100 µm Geometry straight straight and concave Remarks 100 mm diameter only possible with seam Concerning the coatings the following combinations are possible: Nickel belts Stainless steel belts PFA sleeves PFA spray coatings or PFA sleeves Silicone and PFA sleeves Silione and PFA spray coatings or PFA sleeve

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

The requirements: homogenous and fine-pored cell structure tight tolerances of silicone foam density defined concave or convex surface shape non-stick top coatings (e.g. PFA sleeves) minimal odor through reduction of volatiles (VOC)

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our all-ceramic bearings are characterised by their high corrosion resistance to seawater and various chemicals. They are therefore used, for example, in the chemical industry, in the food and beverage industry, in shipping and in chlorine systems. We can manufacture our full ceramic ball bearings with rings and balls made of zirconium oxide (ZrO2) or silicon nitride (Si3N4), depending on the application. They are available with full balls or with cages made of PEEK or PTFE. The runout accuracies common with precision steel bearings cannot be achieved with all-ceramic bearings, so speed values have to be reduced. Ceramic materials are harder than steel, but also more brittle. Silicon nitride in particular has a low elongation at break and tends to break under tensile stress without prior plastic deformation. We take this into account when selecting the optimum bearing solution for your specific requirements.

Request for a quote

HYDROSTAR MESSTECHNIK GMBH

Germany

Air exchange in sealed housings? No Problem! Our pressure equalisation elements (formerly Gothe & Co. GmbH) have proven themselves reliably worldwide. High temperatures and adverse environmental influences provide continuous pressure fluctuations in sealed housings – protect your sensitive electronics and improve the lifetime of electronic devices with our pressure equalisation elements. Reliable reduction of condensate formation Protection of harmful fluids and particles Special Features Flat construction Easy installation (from inside or outside) 100% Salt retention capacity Very robust Diverse versions Air passage of up to 400 ml/min Technical Data Mounting body/cap brass (optional nickel-plated, chrome-plated or stainless steel) Membrane ePTFE (oleophobic) O-Ring NBR (optional EPDM, FKM or silicone) Water ingress pressure > 0,6 bar Protection class DIN EN 60529 IP66, IP68 (installed) Acceptable temperatures - 40 °C … + 80 °C (150°C temporary)

Request for a quoteResults for

Silicon ores - Import exportNumber of results

11 Products