- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- shut-off

Results for

Shut-off - Import export

HERBERHOLZ GMBH

Germany

Applications: Steel Industry / Industrial Combustion Technology / Renewable Energy Technology One-piece body, tight-closing, centric disc Design for mounting between flanges according to DIN EN 1092-1 or ASME B16.5 Face-to-face length according to DIN EN 558-1-R20. Leakage rate A according to DIN EN 12266-1. permissible operating pressure 5 bar For all gases according to DVGW worksheet G 260 Safety shut-off valve according to EN161 class A (closing time < 1s)

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Industrial Combustion Technology / Steel Industry One-piece body, tight-closing, centric valve disc With blow-out proof shaft Version for mounting between flanges according to DIN EN 1092-1 Face-to-face length according to manufacturer’s standard Leakage rate A according to DIN EN 12266-1 permissible operating pressure 2 bar For all flammable gases according to DVGW worksheet G 260, EN 437 and other neutral gases Safety shut-off valve according to EN161 class A Approval according to DIN EN IEC 61511, up to and including SIL 3

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Industrial Combustion Technology / Steel Industry One-piece body, tight-closing, centric disc Lug-type body for flanges according to DIN EN 1092-1 or ASME B16.5 Face-to-face length according to DIN EN 558-1-R20. Leakage rate A according to DIN EN 12266-1. permissible operating pressure 5 bar For all gases according to DVGW worksheet G 260 Safety shut-off valve according to EN161 class A (closing time < 1s)

Request for a quote

HERBERHOLZ GMBH

Germany

Applications:Steel Industry / Industrial Combustion Technology / Renewable Energy Technology One-piece body, tight-closing, centric disc With blow-out proof shaft Design for mounting between flanges according to DIN EN 1092-1 Face-to-face length according to DIN EN 558-1-R20 Leakage rate A according to DIN EN 12266-1 permissible operating pressure 10 bar, from DN 350 ≤ 1.5 bar For all flammable gases according to EN 437 and other neutral gases Safety shut-off valve according to EN161 class A (closing time < 1s) Approval according to DIN EN IEC 61511, up to and including SIL 3

Request for a quote

J.D. NEUHAUS GMBH & CO. KG

Germany

JDN air hoists mini Carrying capacities: 125 kg, 250 kg, 500 kg, 980 kg Air pressure: 6 bar Standard Features interesting and inexpensive alternative even to hoists with other driving media suitable for lube-free operation suitable for application in hazardous areas (Explosion protection) few components only for easiest maintenance wear resistant motor braking system light weight for easy handling also suitable for horizontal pulling extremely sensitive lever control with emergency shut-off valve, max. control length 6 m available lifting heights: 3m, 5m, 8m with chain box as standard with manual trolley as option

Request for a quote

TROTEC GMBH

Germany

Additionally, the TTK 30 E is provided with a whole variety of other features of the Comfort series. These include the laundry drying and the timer function. A child lock protects against accidental change once settings are selected. Moreover, the dehumidifier has a two-stage blower, an overfill protection with auto shut-off, as well as a level warning light when the water tank is full. Here are some practical advantages at a glance: Hygrostat controlled dehumidification Auto modes between 30 and 80% RH in 5% intervals Once the desired humidity level is reached, the compressor switches off automatically. The fan continues to run and if levels are exceeded the device is activated automatically. Color LED display of current humidity Display of relative humidity Laundry drying function Timer function with 2 air flow settings Level warning light at full water tank Overfill protection with auto shutdown

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Ultrasonic flowmeter for high temperature gas and steam As the OPTISONIC 8300 provides a large measurement range and does not require recalibration, the installation can be simplified and costs reduced. For example since the flow sensor does not need to be removed, shut off valves and a bypass are not required. Also thanks to the large measurement range, a dual range measurement setup is not required. Traditional steam measurement solutions need continuous attention and recalibration to guarantee proper operation. As the diagnostics of the OPTISONIC 8300 enables it to look after itself, it does not require any attention. Even periodically recalibration is not required since the OPTISONIC 8300 provides excellent long term stability. Periodical verification of the proper functioning of the device can easily be done using the diagnostics as required.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

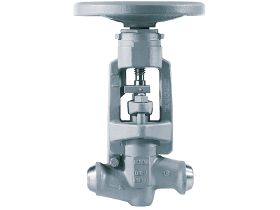

High-pressure shut-off valves type NORI500-ZXSV - PN500

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

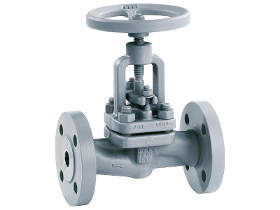

Shut-off valves type NORI320- ZXSF - PN320

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Shut-off valves type NORI160-ZXSF PN63-160

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Shut-off valves type NORI160-ZXLF PN63-160

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Shut-off valves type NORI160-ZXS - PN63-160

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Shut-off valves type NORI160-ZXL PN63-160

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Shut-off valves type NORI320- ZXLF PN320

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Shut-off valves NORI40 ZXSF

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Shut-off valves type NORI40 ZXLB PN40

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ACI INDUSTRIEARMATUREN GMBH

Germany

Shut-off valves type NORI40 ZXS - PN25/40

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Shut-off valves type NORI40 ZXL PN25/40

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Throttle Valves for In-Line Assembly DV ▪ Throttle and shut-off the flow of liquid media in both directions ▪ Designed for in-line assembly with female BSP, NPT and SAE threaded connections ▪ Graduated turning knob and coded spindle to accurately control flow ▪ Set-screw located on side of turning knob to lock valve in position ▪ Panel mounting nuts available on request ▪ Maximum working pressure: up to 350 bar / 5000 PSI Throttle Valves for Manifold Mounting DVP ▪ Throttle and shut-off the flow of liquid media in both directions ▪ Designed for manifold mounting with either 4 or 6 mounting holes ▪ Graduated turning knob and coded spindle to accurately control flow ▪ Set-screw located on side of turning knob to lock valve in position ▪ Panel mounting nuts available on request ▪ Maximum working pressure: up to 350 bar / 5000 PSI Throttle Valves for Cartridge Assembly DVE ▪ Throttle and shut-off the flow of liquid media in both directions ▪ Designed for direct installation into...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Pressure Compensated Throttle Check Valves PNDRV ▪ Throttle and shut-off the flow of liquid media in direction A-B (free flow in reverse direction) ▪ With pressure compensating feature via built-in compensating piston ▪ Designed for in-line assembly with female BSP, NPT and SAE threaded connections ▪ Graduated turning knob to accurately control flow ▪ Set-screw located on side of turning knob to lock valve in position ▪ Panel mounting nuts available on request ▪ Maximum working pressure: 210 bar / 3000 PSI

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Throttle Check Valves for In-Line Assembly DRV ▪ Throttle and shut-off the flow of liquid media in direction A-B (free flow in reverse direction) ▪ Designed for in-line assembly with female BSP, NPT and SAE threaded connections ▪ Graduated turning knob and coded spindle to accurately control flow ▪ Set-screw located on side of turning knob to lock valve in position ▪ Panel mounting nuts available on request ▪ Maximum working pressure: up to 350 bar / 5000 PSI Throttle Check Valves for Manifold Mounting DRVP ▪ Throttle and shut-off the flow of liquid media in direction A-B (free flow in reverse direction) ▪ Designed for manifold mounting with either 4 or 6 mounting holes ▪ Graduated turning knob and coded spindle to accurately control flow ▪ Set-screw located on side of turning knob to lock valve in position ▪ Panel mounting nuts available on request ▪ Maximum working pressure: up to 350 bar / 5000 PSI

Request for a quote

FILLTECH GMBH

Germany

Customer specific and automatic Filling Stations for several industries and gases. Highlights Highly specialized systems with low overall costs One stop station for all necessary handling Individual solutions on demand 24/7 Back-up support available General capacity: 1000 CO 2 cylinders/hour Filling Options Valve set (fill and relieve) Valve connection Hoses, connections, pipes Weighing Terminals Various digital terminals SysTec IT 1000 / IT 3000/ IT 8000 industrial weighing terminal Connection as second scale to other filling units Optional printer and communication interfaces Automatic tare setting Automatic shut-off at target weight

Request for a quote

TEST GMBH

Germany

One-column testing device for the motorized transmission of compressive and tensile forces of up to 1000 N. Integrated measurement and automatic shut-off for interruption upon reaching limits (force/stroke) available.

Request for a quote

TEST GMBH

Germany

Two-column testing device for the motorized transmission of compressive and tensile forces of up to 5000 N. Integrated incremental position measurement and automatic shut-off for interruption upon reaching limits (force/stroke) available.

Request for a quote

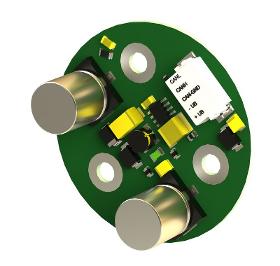

TWK-ELEKTRONIK GMBH

Germany

Recording of the angular position by means of a Hall sensor and signal processing including generation of the output signal - in addition to the angular position, a speed signal can also be output in digits / time unit - electrical connection via screw clamp (5-pin, conductor cross-section max. 0.5 mm²) or PTFE pigtail connector, 300 mm long - a CAN controller at the output enables connection to the CANopen network. According to CANopen Application Layer and Communication Profile, CiA Draft Standard 301, Version 4.1 and according to Device Profile for Encoders CiA Draft Standard Proposal 406, Version 3.0 and CANopen Layer setting Services and Protocol (LSS), CiA DSP 305. In the multiturn version, the number of revolutions is recorded in a counter. The position value is saved on shutting off the supply voltage. In voltage-free condition, the position value is recorded on movement of the shaft in a range of ≤ ± 90°.

Request for a quote

BEULCO GMBH & CO. KG

Germany

Valve tapping bridge with service shut-off and for tapping 1 "- 2". Combination rubber insert chambered with several micro-sealing lips. Seal material according to KTW / W 270. Seal the bore with the auxiliary shut-off via the side outlet and seal it after tapping until the valve bonnet is reassembled. For each dimension, a top with matching clamp. scope of application • for plastic pipe (PE or PVC) DN 50 - 200 • for sluice-free, upper tapping under pressure by means of Rehbein auxiliary valve • for water up to PN 16

Request for a quote

BEULCO GMBH & CO. KG

Germany

High-lift valve fitting with ball shut-off for tapping without the use of an auxiliary shut-off. For the entire nominal diameter range from DN 80 to DN 500, only one connection piece with patented Vario seal is required. The Vario seal is factory-mounted in the connection piece, which avoids unintentional twisting or falling out on the construction site becomes. The sealing material complies with the KTW recommendations of the UBA and the requirements acc. DVGW worksheet W 270. — for tapping 1 "-1 1/2" — with Vario seal — with ball shut-off — with Niro overdrive spindle — with plastic inner lining — Surface protection EKB Blue Outgoing versions: 1 "IG -2" IG or VLUX

Request for a quote

BEULCO GMBH & CO. KG

Germany

Flat slide with operating shut-off for water up to PN 16 (optional for gas up to PN 5) and for top tapping 1 "- 1½" under operating pressure. Thread outlet 1 "- 1½" parallel to the supply line. Connection piece with extremely low height. Outlet by means of elbow union. Front and main shut-off with externally driven, chrome-plated switching ball. Nominal diameter range DN 80 - 500 with only one connection piece with patented Vario seal. Seal material is from DVGW to KTW / W 270. Scope of application • for cast iron, steel and AZ pipes DN 80 - 500 • For sluice-free tapping under pressure without auxiliary valve • for water up to PN 16 • optional for gas up to PN 5

Request for a quoteResults for

Shut-off - Import exportNumber of results

31 Products