- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- shaft mounting

Results for

Shaft mounting - Import export

HERBERHOLZ GMBH

Germany

Applications: Industrial Combustion Technology / Steel Industry One-piece body, tight-closing, centric valve disc With blow-out proof shaft Version for mounting between flanges according to DIN EN 1092-1 Face-to-face length according to manufacturer’s standard Leakage rate A according to DIN EN 12266-1 permissible operating pressure 2 bar For all flammable gases according to DVGW worksheet G 260, EN 437 and other neutral gases Safety shut-off valve according to EN161 class A Approval according to DIN EN IEC 61511, up to and including SIL 3

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Steel Industry / Industrial Combustion Technology / Renewable Energy Technology One-piece body, tight-closing, centric disc With blow-out proof shaft Design for mounting between flanges according to DIN EN 1092-1 Face-to-face length according to DIN EN 558-1-R20 Leakage rate A according to DIN EN 12266-1 permissible operating pressure 10 bar, from DN 350 ≤ 1.5 bar For all flammable gases according to EN 437 and other neutral gases Approval according to DIN EN IEC 61511, up to and including SIL 3

Request for a quote

HERBERHOLZ GMBH

Germany

Applications:Steel Industry / Industrial Combustion Technology / Renewable Energy Technology One-piece body, tight-closing, centric disc With blow-out proof shaft Design for mounting between flanges according to DIN EN 1092-1 Face-to-face length according to DIN EN 558-1-R20 Leakage rate A according to DIN EN 12266-1 permissible operating pressure 10 bar, from DN 350 ≤ 1.5 bar For all flammable gases according to EN 437 and other neutral gases Safety shut-off valve according to EN161 class A (closing time < 1s) Approval according to DIN EN IEC 61511, up to and including SIL 3

Request for a quote

IGUS® GMBH

Germany

iglidur® flange bearing d1 [mm]: With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. When to use iglidur® flange bearings? When you want a screw flanged bearing When a clip bearing solution is not satisfactory as a sheet metal feedthrough When there is a housing with very rough tolerances When the tight fit of a press-fit bearing is not sufficient as an axial securing When not to use them? When an additional angle compensation is required igubal® flange bearing When a screw connection is not possible iglidur® clip bearing When a large guide length is necessary iglidur® G General features With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. The design enables high loads with minimum demand on the precision of the housing. iglidur® maintenance-free flange bearings are available in four materials - iglidur® G, iglidur® J, iglidur® X and iglidur® A180. Thus, with this design, a very wide range of applications - from the universal bearing through the highest wear resistance or temperature resistance (up to +250°C) up to FDA-compliant bearing solutions - can be covered. Installation Dependent on the stressing capacities, various mounting types are used. For low radial loads, it is enough to mount the iglidur® flange bearing with just two screws on a surface. For higher radial loads, it is advisable to support the iglidur® flange bearing in a bore on the reinforced side in the load direction. Large tolerances are permitted for this bore, as it is only to additionally support the iglidur® flange bearing. In order to support still higher radial loads, the iglidur® flange bearing can be press-fitted with the longer side in an H tolerance bore. The additional screw connection secures the firm seating of the bearing in the housing. For the mounting of the iglidur® maintenance-free flange bearing, no special tools or devices are necessary. The alignment of the bearing in multiple mounted shafts is easily possible at the installation. Available materials: iglidur® G, iglidur® A180, iglidur® J and iglidur® X The mounting of the iglidur® flange bearing: Simple and safe iglidur® flange bearing d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

Thrust bearing / Spherical axial bearings from igus d1 [mm]: Mechanical properties The self-aligning spherical igubal ® thrust bearings are very easy-to-mount units, which help to compensate for errors and prevent misalignments. The thrust bearing housing pad is made of the impact-resistant, stiff, thermoplastic composite material igumid G. The standard thrust bearing washer is made of iglidur® W300. This combination provides particularly good gliding and wear properties in relative movements. Loads The load carrying capacity of the spherical igubal® thrust bearing is very high in normal ambient temperature. In particular cases the load carrying capacity of the axial bearings should be checked in a practical trial with high constant loads and at higher temperatures. Coefficients of surface friction and speeds Taking the radial loads into account, maximum surface speeds up to 0.5 m/s rotating can be attained. Installation The axial bearing pad is mounted flush and secured. The spherical washer glides loosely in the pad and is held by the shouldered shaft mounted on it. Delivery program As standard, the spherical igubal® axial bearings are supplied in sizes of 5 to 20 mm. For other dimensions, please contact us. Special features Simple assembly Compensation of misalignments Compensation of edge loads Very good gliding and wear properties, low installation space When to use it? When you want to save weight When freedom from corrosion is required When a bearing with good friction coefficients is sought When not to use? When very heavy loads act When constant temperatures of more than +80℃ occur When high rotary speeds must be implemented. Thrust bearing / Spherical axial bearings from igus d1 [mm]:

Request for a quote

IGUS® GMBH

Germany

igubal® rod end bearing, female thread With female thread in metric and inch dimensions igubal® rod end bearing, female thread igubal® rod end bearing, male thread With male thread in metric and inch dimensions igubal® rod end bearing, male thread igubal® rod end bearing CL For simplified mounting, with inner and outer threads in metric dimensions igubal® rod end bearing CL igubal® rod End Bearing CL DT For simplified installation, detectable with female thread in metric dimensions igubal® rod End Bearing CL DT igubal® fitting screw, mm Fitting screw with circlip igubal® fitting screw, mm When to use it? When you want to save weight When rotating, oscillating and linear movements should be implemented When high-frequency oscillations/vibrations predominate When a low-noise operation is desired When an electrically insulating part is required When freedom from corrosion is desired For combinations with pneumatic cylinders and gas struts When chemical resistance is required When high stiffening is required When not to use? When you have temperatures above +80°C (then HT options) When rotation speeds in excess of 0.5 m/s should be implemented When very high tensile and lateral loads prevail When applications should be implemented with hydraulic cylinder When dimensions over 30 mm are needed igubal® rod end bearing, female thread With female thread in metric and inch dimensions igubal® rod end bearing, female thread igubal® rod end bearing, male thread With male thread in metric and inch dimensions igubal® rod end bearing, male thread igubal® rod end bearing CL For simplified mounting, with inner and outer threads in metric dimensions igubal® rod end bearing CL igubal® rod End Bearing CL DT For simplified installation, detectable with female thread in metric dimensions igubal® rod End Bearing CL DT igubal® fitting screw, mm Fitting screw with circlip igubal® fitting screw, mm Special properties of the igubal® rod end bearings Maintenance-free, self lubricating High stiffening Very high fatigue strength in varying loads Compensation for alignment errors Compensation of edge loads Insensitive to dirt, dust and lint balls Resistant to corrosion and chemicals High dampening qualities Suitable for rotary, oscillating and linear movements Very low weight Dimensional series K and E, dimensions according to DIN ISO 12240 Version with metal sleeve in the spherical ball for enhanced torque Tolerances igubal rod end bearings can be used, according to the application, with different tolerances. They are designed with a large clearance in the standard product, which enables a secure operation even under high peripheral speeds. The bore of the inner ring has a tolerance according to E10. The shafts should have a tolerance between h6 and h9. Please contact us in case you require lower or more bearing tolerances. Loads igubal® rod end bearings take high forces in normal ambient temperatures, have excellent dampening properties and weigh only a fifth of the conventional metallic bearing housing. In particular cases the load carrying capacity of the rod end bearings should be checked in a practical trial especially with high constant loads and at higher temperatures. Coefficients of surface friction and speeds Rotary motions of the mounted shaft take place directly in the bearing ball made of iglidur® W300. The advantage of this plastic/steel plain bearing is that high speeds can be achieved in dry operation. Taking the radial loads into account, maximum surface speeds up to 0.5 m/s rotating can be attained. The maintenance-free igubal® rod end bearings casually permit linear and oscillating movements of the shaft. Delivery program igubal® rod end bearings are available in the dimensional series K and E for shaft diameters of 2 to 30 mm in all dimensions according to DIN ISO 12240, and of course respectively in the Form A - with male thread and Form B - with female thread The dimensional series K and partly E are moreover available in inch dimensions and – as special version – with a stainless steel sleeve in the spherical ball. Thereby an essentially higher tightening torque is possible than with the plastic spherical ball. Please ask us for other sizes. igubal® rod end bearings - Applications igubal® rod end bearings - Applications Temperatures Dimensional series K in A+B variants for temperatures upt to +200°C (HAT material).

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

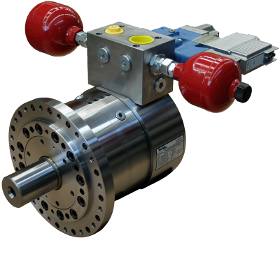

Thanks to a wide range of accessories, Hense operators can be individually configured for a wide variety of applications and optimally matched to the function of the overall system. To ensure perfect and safe operation, we are on hand to help you select and optimally coordinate all components.Servo valves, proportional valves and switching valves with different nominal sizes Pulsation damper for smoothing vibrations and uneven flow rates Subplates for positioning valves and pulsation accumulators close to the motor High-resolution rotation angle sensors that are coupled directly to the swivel motor shaft by means of a torsionally rigid coupling Pressure sensors Torque measuring shafts or reference torque measuring disks Clamping sets, shrink disks or profiled hubs for torque transmission Torsionally rigid couplings for reliable torque transmission with simultaneous shaft displacement Angled flanges for mounting the swivel motors parallel to the axis

Request for a quote

RUHRGETRIEBE KG

Germany

Single-stage gear with ingoing and outgoing shaft Gear Type: SN17B Mounting: Gear Foot Ausgangswelle: solid shaft Additional Data: — Ball bearings for ingoing and outgoing shaft — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

RUHRGETRIEBE KG

Germany

Single-stage gear drive with hollow shaft Gear Type: SN10FH Motor Type: Three-Phase Mounting: Flange Shaft design: Hollow Shaft Additional Data: — Ball bearings for motor and gear — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

RUHRGETRIEBE KG

Germany

Single-stage gear with ingoing and outgoing shaft Gear Type: SN17A Mounting: Gear Foot Ausgangswelle: solid shaft Additional Data: — Ball bearings for ingoing and outgoing shaft — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Immersion Pumps are plain centrifugal pumps with the impeller fitted on the driving shaft extension. They are mounted on top of the container, the pump extension being immersed in the coolant. The maximum coolant level must stay a few mm/inches below the mounting flange. The STA serie offers a (SAE) flange with pressure gauge connection port. The flange can be rotated for either horizontal or vertical pipe connections. Volumetric delivery: up to 5000 l/min Delivery head: up to 120 m Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Immersion Pumps are plain centrifugal pumps with the impeller fitted on the driving shaft extension. They are mounted on top of the container, the pump extension being immersed in the coolant. The dimensions are based on standard specification EN 12157. The maximum coolant level must stay a few mm/inches below the mounting flange. Volumetric delivery: up to 500 l/min Delivery head: up to 13 m Please contact us for delivery quantity

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The potentiometer grinding track is embedded in a blue plastic housing and is picked up by precious metal grinders. The back of the housing is sealed dust-tight with a cover. The stainless steel drive shaft is mounted in bushings. Up to 3 potentiometer levels can be lined up one behind the other with a common wiper shaft. The levels can be adjusted against each other. Delivery is possible with or without mechanical stops. The PP 27 potentiometers are used as setpoint adjusters and as actual value and reference potentiometers in control and measuring circuits.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The angle transducers have a magnetic scanning according to the HALL principle. Due to the robust design, critical and interference-free applications in harsh environments can be realized. They have a robust housing (wall thickness > 5 mm) made of aluminium or stainless steel, shaft and ball bearing made of stainless steel, shaft with flattening, rotor with shaft and permanent magnet mounted in prechamber, sensor circuit consisting of ASIC with Hall elements and interface electronics housed in closed main chamber. Two models are available: For low and high temperature applications. The model for low-temperature use is equipped with a special grease for bearings and shaft seal. Seals and shaft seal are made of PTFE. Cable gland with clamping jaw pressure screw and silicone seal. The high temperature model is without shaft seal. Under the rear cover, there is a signal path switch (CW/CCW). On the side there is a preset button (4 mA) placed under a screw plug.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The angle transducers have a magnetic scanning according to the HALL principle. Due to the robust design, critical and interference-free applications in harsh environments can be realized. They have a robust housing (wall thickness > 5 mm) made of aluminium or stainless steel, shaft and ball bearing made of stainless steel, shaft with flattening, rotor with shaft and permanent magnet mounted in prechamber, sensor circuit consisting of ASIC with Hall elements and interface electronics housed in closed main chamber. Two models are available: For low and high temperature applications. The model for low-temperature use is equipped with a special grease for bearings and shaft seal. Seals and shaft seal are made of PTFE. Cable gland with clamping jaw pressure screw and silicone seal. The model for high temperature use is without shaft seal. Under the rear cover there is a signal changeover switch (CW/CCW). On the side there is a preset button (4 mA) placed under a screw plug.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Robust aluminium or stainless steel housing (wall thicknesses up to 5 mm) - stainless steel shaft and ball bearing - ball bearing with Simmer ring, rotor with shaft and permanent magnet mounted in pre-chamber - sensor circuit consisting of ASIC with Hall elements and interface electronics in enclosed main chamber - housing protection type IP 69K additionally cast - electrical connection via cable (open cable ends).

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Robust aluminium or stainless steel housing (wall thicknesses up to 5 mm) - stainless steel shaft and ball bearing - ball bearing with Simmer ring, rotor with shaft and permanent magnet mounted in pre-chamber - sensor circuit consisting of ASIC with Hall elements and interface electronics in enclosed main chamber - housing protection type IP 69K additionally cast - electrical connection via cable (open cable ends).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CINCHSEAL EUROPE GMBH

Germany

The newly developed CinchSeal®series is applicable for machines in food production, screw conveyors and other bulk material handling equipment, in the pharmaceutical industry as well as in the chemical industry. It is made of 316 stainless steel or other material according to customer requirements. standard features ✔ lower maintenance due to unique self-adjusting design ✔ prevent leaks and material loss and protect gearboxes, bearings and shafts from damage ✔ mounting pattern suitable for standard bearings ✔ handles dry powders, pastes, slurries, and liquids ✔ USDA- and FDA-certified sealing products for use in meat, poultry, and dairy applications ✔ needs 30% less energy than packing seals ✔ temperature ranges -40 °C to 220 °C ✔ designed to accommodate longitudinal expansion and axial runout of the shaft ✔ pressurization with sealing air, 0.3 to 0.6 bar above the pressure of the operating vessel

Request for a quoteResults for

Shaft mounting - Import exportNumber of results

19 Products