- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- shaft couplings

Results for

Shaft couplings - Import export

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

TOK Coupling System * Elements available in different torsional stiffnesses * Suited for highest speeds * Adaptation to DIN or SAE flanges or according to specification * Self-centering, backlash-free and maintenance-free * Optional reduction of the torsional stiffness through the use of two elements * Compensation of axial, radial and angular misalignments * Light-weight construction through the use of high-strength aluminium * Variable mounting lengths through telescopic intermediate shafts, freely pluggable * For use up to TKN depending on the application

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

Highly torsionally flexible coupling ARCUSAFLEX-VSK for drive shafts * Linear torsional deflection characteristic * Elements available in different torsional stiffnesses * Enhanced damping capacity through frictional damping * Maintenance-free coupling bearings * Radial bearing close to the cardan joint * A variety of designs for different cardan shaft configurations * Many types with SAE connection dimensions or as specified * Compact construction, the highly flexible element being protected by the housing * Fail-safe device visible from the outside for ease of inspection

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

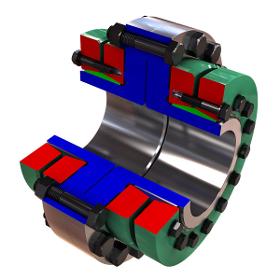

MULTI CROSS RILLO couplings are highly torsionally flexible tyre couplings with progressive torsional deflection haracteristic. The salient feature of the MULTI CROSS RILLO shaft couplings is that the coupling hubs are supplied with commercially available taper bushes for nominal torques of up to 11500 Nm. This allows easy and time saving mounting of the coupling hubs on the shaft. Special tools are not required. The most important attributes and advantages of the highly flexible MULTI CROSS RILLO couplings: High torsional flexibility with progressive torsional deflection characteristic High compensating capability for axial, radial and angular misalignments Easy and time saving mounting of the coupling hubs thanks to the use of taper bushes Radial change of the rubber element without axial movement of the coupled machines Backlash-free torque transmission even in case of alternating directions of rotation High torsional vibration and shock load damping capability Noise level...

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

REIBO couplings are torsionally flexible pin-type couplings which compensate for radial, axial and angular shaft displacements. REIBO couplings are designed for positive (fail safe) torque transmission and for absorbing vibrations and torque surges. Salient features of the torsionally flexible REIBO couplings: Compensation of axial, radial and angular misalignments Shock load and vibration absorbing capability Fail safe operation Available in 18 sizes: from 150 Nm - 350 000 Nm Ease of assembly and ease of alignment Plug-in mounting facility No maintenance required sAvailable in different types or as special designs We are glad to see that you are interested in our product line and are happy to answer all questions! Please use our contact form or call us: +49 234 959160. For additional information regarding designs, sizes or technical details please make use of our download opportunities below. Product details General technical description The two coupling hubs are of identical...

Request for a quote

TAS SCHÄFER GMBH

Germany

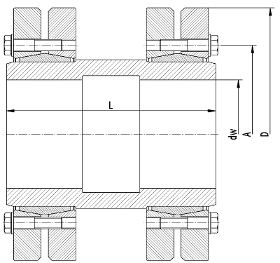

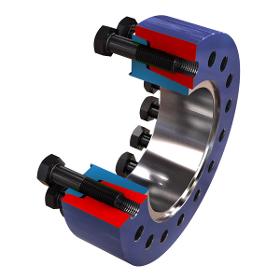

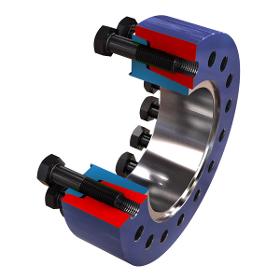

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. The external clamping system does not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean....

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a hydraulic lange coupling (hereinafter called FKH) is the safe connection of two shafts. For example, between a drive shaft and a transmission shaft. The FKH produces a rigid and backlash-free connection between the shafts. This connection is mainly used to transmit torque, but can also absorb bending moments. The FKH is located in the power low. It is installed by sliding the FKH onto the shaft and the subsequent tightening of the hydraulic system. By using conical surfaces the inner diameter reduces and the radial pressure is built up. After clamping the FKH will be locked mechanically and the hydraulic pressure will be removed. Due to this simple approach, the FKH is suitable for repetitive clamping operations. Advantages of the FKH: • high transmittable torque and bending moments (high friction) • application-speciic design/customization • easy mounting and adjustment because of clearance it • relatively low pressure (closed system) • very rapid...

Request for a quote

TAS SCHÄFER GMBH

Germany

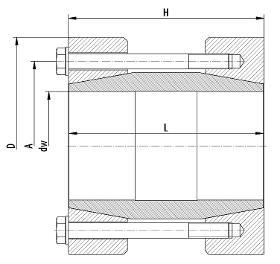

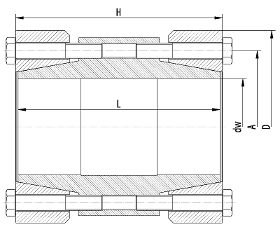

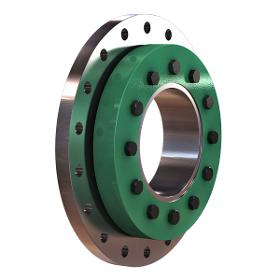

The main function of the rigid flange coupling (FK) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used shrink discs generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. The shrink discs do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the shrink disc. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces between the shaft extensions and flangehubs, as well as the contact surfaces of the flanges, must be free of grease,...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid flange coupling (FK) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used shrink discs generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. The shrink discs do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the shrink disc. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces between the shaft extensions and flangehubs, as well as the contact surfaces of the flanges, must be free of grease,...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid flange coupling (FK) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used shrink discs generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. The shrink discs do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the shrink disc. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces between the shaft extensions and flangehubs, as well as the contact surfaces of the flanges, must be free of grease,...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid flange coupling (FK) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used shrink discs generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. The shrink discs do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the shrink disc. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces between the shaft extensions and flangehubs, as well as the contact surfaces of the flanges, must be free of grease,...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid flange coupling (FK) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used shrink discs generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. The shrink discs do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the shrink disc. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces between the shaft extensions and flangehubs, as well as the contact surfaces of the flanges, must be free of grease,...

Request for a quote

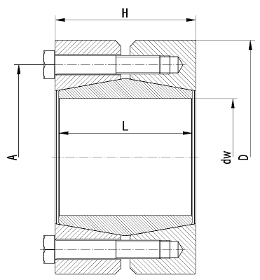

TAS SCHÄFER GMBH

Germany

Use full screen mode The main function of the rigid flange coupling (FKE) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used pressure ring generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. It can also be transmitted axial forces and bending moments. The shrink connection do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the pressure ring. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. The clamping is done manually by means of screwing tools. Optionally with a hydraulic clamping tool. To achieve proper...

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Please note that this product is an accessory. In the "Products" section you will find the corresponding encoders that you can order for your selected article. The linear movement of a 2000 mm long, flexible high strength steel measuring cable is converted into a rotational movement by a measuring drum. The measuring drum, which has a circumference of 102.4 mm, is coupled to the shaft of the encoder. A change of displacement in the measuring cable then corresponds to a change in angle on the shaft of the angle encoder. The restoring force of a spiral spring holds the measuring cable tight and prevents errors due to slackness. The cable is wound with adjacent turns in a reproducible manner on the drum due to the movement of the drum on a spindle.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAYFRAN GMBH

Germany

The solution for 1 - 3 machine tools. Dual shaft crusher, built into machine pump back systems, that has been developed for hard and brittle materials. Suitable for small amounts that are fed continuously. Compact design with oversized bearings, shafts and couplings.

Request for a quoteResults for

Shaft couplings - Import exportNumber of results

19 ProductsCompany type

Category