- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- separating

Results for

Separating - Import export

BEKO TECHNOLOGIES GMBH

Germany

A more economic solution for an environmentally sound condensate management is the decentralised oil-water separation directly at the source. Condensate which was processed with ÖWAMAT can be directly introduced as cleaned water into the sewerage system. The devices have a national technical approval and do not require a permit according to the law on water. In addition, the ÖWAMAT oil-water separators do not create any energy costs, boast enormous filter service lives and can be retrofitted into older systems without difficulty.

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

The energy costs of a compressed-air system are decisively influenced by the pressure drop occurring during compressed-air filtration. To maintain the required operating pressure, this pressure drop needs to be compensated by correspondingly higher compressor performance. The consequence: increased energy demand, premature wear of the compressor ... and therefore higher costs. The better solution: CLEARPOINT compressed-air filters by BEKO TECHNOLOGIES.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Design & construction Our Schulz separate fixing clip assits installation and compensates for irregular bore diameter. Installation Our Schulz clamp spring washers/fixing clips for euro ball transfer units allow ball transfers units to be mounted and removed from the installation (upper) side. Our clips requires a minimum plate thickness of 3 mm to grip securely.

Request for a quote

TROTEC GMBH

Germany

WATER SEPARATOR WA 4I MULTIQUBEWater separator WA 4i for combination with MultiQube insulation layer dryers The new WA 4i is provided with an integrated micro filter system with low-maintenance magnetic lock filter compartment to take in micro filter cartridges with a threefold filter element. This makes the WA 4i a versatile integral solution with all pre-HEPA filter stages in only one device. Advantage: improved flow-optimized filter technology, quicker setup, decreased material and space requirements – no separate additional micro filter housings required. With respect to insulation drying of surfaces sized up to 40 m², no other model is quite fit to hold a candle to this separator, for despite its ultra-compact dimensions the WA 4i comes fully equipped with numerous practice-oriented detailed solutions, such as a construction yet easier to maintain, TTKwic quick couplings, cable holder, residual water drainage and much more.

Request for a quote

STOTTROP-TEXTIL GMBH & CO KG

Germany

High performance low-e fabric A2 The climatic separation of building parts or the thermal separation between the outside of buildings and the interior is usually achieved by a thick layer of insulation. GLASS REFLECT offers a different approach: the high-performance low-e coatings on the energy-saving glass fabric reflect heat radiation almost completely. Depending on requirements, the energy-saving fabric can maintain the coolness of a room while keeping heat from outside at the same time Thermographic testing according to DIN EN 13187: A black body heater at 200 °C is directed onto the center of the back of the fabric. Result: The heat radiation is reflected by more than 96% ! The robust fabric is less than 0.5 mm thick. This thin architectural fabric offers significant advantages for installation and ensures the best rolling behavior even after tens of thousands of rolling cycles.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

F.E.S. GMBH

Germany

Chain Magnetic Separator are used for the cleaning of liquids contaminated with magnetizable solid particles and foreign oils. F.E.S. separator systems can be used in full-flow or bypass cleaning applications. The separation performance varies depending on the level of contamination and the volume flow rate. Note: The separator systems can be supplied via a separate supply pump, existing system pumps (with sufficient reserve capacity within the existing system components), or a free inlet (with sufficient geodetic height difference). Advantages: No filter aids required High separation efficiency Large throughput capacity Large active separation surface due to favorable separation geometry and optimal arrangement of magnets Low wear and tear Operating Principle: The contaminated liquid is supplied to the separator through the flange (1) located at the bottom.

Request for a quote

BERNSTEIN AG

Germany

The SK safety position switch is an industry standard and can be used in virtually any application. Its versatility is improved by the variable actuator head and two actuator openings. The design safety attributes befitting to VDE 0660 T200, IEC 60947-5-1 and the test regulations GS-ET 15, the SK is particularly qualified for personal protection applications. Actuators can be repositioned by 180 degree. Two actuators openings which designs horizontal as well as vertical operation possible. This product has a high standard quality and very reliable as well as user friendly device. Additionally, had meet the requirements for its excellent quality.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Centrifugal force separator for powder recovery. Cyclone separator A cyclone is a centrifugal force separator and essentially consists of three parts: The intake cylinder, the cone and the immersion tube. In the intake cylinder, the air/particle mixture is brought into a circular path by means of tangential injection. Due to the taper of the subsequent cone, the speed of rotation increases sharply, so that the particles are pressed by centrifugal force against the outer wall and decelerated by friction, causing them to drop out of the air current and fall down. The cleaned air leaves the cone in an upward direction via the central immersion tube.

Request for a quote

STRONG MAGNETS GMBH

Germany

Magnetic separator is one of the most widely used and versatile machines in the industry. It is used to remove iron powder from the reused powder granules. Magnetic separators are widely used in resource recovery, wood industry, mining, kiln industry, chemistry, food and other workshops. The magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with particle size less than 3mm. It is also used for iron removal of coal, nonmetallic ore, building materials and other materials. The magnetic system of the magnetic separator is made of high quality ferrite material or rare earth magnets. The average magnetic induction intensity of the barrel surface is 100600 mT.

Request for a quote

GHM MESSTECHNIK GMBH

Germany

Filter inserts 250 to 600 Media temperature up to 150 C Nominal widths DN 15 to DN 80 Red brass/brass materials

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

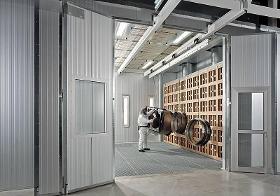

Spray walls and spray booths with dry separation via cartons. For lower utilisation times or overspray quantities RES dry spray booth For lower utilisation times or smaller overspray quantities, spray systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RES enables individual adaptation to the respective case of need. The filter system of the RES dry spray wall consists of individual square cardboard boxes. A sheet metal frame serves as a support structure for the filter box. In order to save costs, there is a possibility to vary the individual filter boxes in the spray booth, without exchanging all of the filter elements. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The basic version consists of a wall with a two-fold filter stage. Paper filter boxes form the first filter stage. A glass fibre fine filter arranged directly behind it represents the second filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The spray booth can additionally be equipped with removable or fixed side and ceiling panels. The RES dry spray booth is available in galvanised sheet metal or in stainless steel. Advantages Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. Once it is saturated, the filter box is removed from the sheet metal frame and disposed of in an environmentally-friendly manner.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via pre-filters and fine filters. Spray walls and spray booths with dry separation For lower utilisation times or overspray quantities, spraying systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RTS enables individual adaptation to the respective case of need. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The entire spray wall and the drip tray are made of galvanised sheet steel. The basic version consists of a wall with a two-fold filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The first filter stage is formed by a paper filter or a baffle plate filter, consisting of two rows of galvanised sheet metal lamellae arranged one behind the other. A glass fibre fine filter arranged directly behind it represents the second filter stage. The spray wall can additionally be equipped with removable or fixed side and ceiling panels. Each version is also available with floor suction pan, available with an integrated 2-stage filter and grating cover. Accessories In addition, the spray wall can be equipped with various accessories from the Rippert product range, such as explosion-proof lights, energy-saving flaps, turntables, etc. We recommend the installation of a supply air system for the replacement of the exhausted air. Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. For faster cleaning, baffle plate filters should by sprayed with a release agent (e.g. strippable varnish) before being put into operation. Underfloor paint mist extraction With dry separation, consisting of a support structure with attached paper filter, grating cover and a suction duct with air quantity adjustment.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Standard advantages: RTS-Rotation – low-maintenance dry spray booth Overspray dry separation demonstrates its strengths in practice above all when relatively large quantities of paint have to be processed and the overspray portion cannot be reduced any further. Spray booth with dry separation are usually equipped with disposable filters or manually regenerative filters. These cause costs for spare filters, maintenance and disposal. In addition to that, operation has to be interrupted in order to exchange the filters. The ‘RTS rotation’ system was developed by Rippert in order to reduce these costs and tooling times. Maintenance intervals and filter service lives are prolonged significantly in comparison with conventional systems due to the new brush pre-filtration. How the ‘RTS-Rotation’ system works Overspray separation in the RTS-Rotation system takes place by means of a pre-filter and a fine filter stage. The pre-filter stage is formed by vertical, slowly rotating brush rollers. The bristles present a very large total surface area and absorb the adhesive particles from the overspray. During the slow rotation, the paint particles can dry on the tips of the bristles. This results in slowly growing cakings on the bristles. Scrapers are mounted in the area behind the brush rollers that continuously remove these cakings from the bristles. The dislodged, hardened material falls into the drawers arranged under the brushes and can thus be simply disposed of. The dry paint dust may often be disposed of as ‘commercial waste’. The brushes otherwise require little maintenance and do not need to be exchanged or renewed. The fine filter stage is formed by a special fleece filter, which is arranged above the brush rollers and must be manually maintained or exchanged in the standard version. The maintenance intervals depend on the paint material used. Automatic cleaning or an external fine filter with automatic cleaning is also possible as an option. Over 10 years of operational experience shows that around 75 to 95% of the overspray is separated out by the pre-filter stage and the rest by the fine filter stage. The degree of separation depends strongly on the type of paint and the drying reactivity during the flying phase. Use of the RTS-Rotation with the following paints Before practical use, the paints are tested and approved in Rippert’s own pilot plant. Stove enamels and 100% UV paint systems cannot be used. The horizontal version Furthermore, it is possible to use the system as a horizontal underfloor extraction system. This version is used, for example, by a machine manufacturer for large parts. In addition, a drag conveyor with gulley extraction is used there in order to automatically transport the particles cleaned off the brushes out of the pit. Conclusion The RTS-Rotation system is particularly useful when relatively large quantities of paint with an unavoidable overspray portion have to be processed, as otherwise a great deal of residual waste would result using conventional technology. Compared to water-sprinkled spray walls and normal dry spray booths the amortisation period is shorter; it is frequently less than two years.

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: ASD 70-03-077 Manufacturer: GEA Westfalia Separator Description: Self-cleaning disc centrifuge Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for concentration/purification Liquid discharge: With single centripetal pump Constructional features: Standard design Design of hood and sediment collector: Sanitary design Type of drive: Flange type motor vertical

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: TKC 100-86-076 Manufacturer: GEA Westfalia Separator Description: Chamber separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for clarification Liquid discharge: With centripetal pump under pressure Constructional features: Standard design Design of hood and sediment collector: Sanitary design Type of drive: Flange type motor horizontal

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: TKC 100-06-576 Manufacturer: GEA Westfalia Separator Description: Chamber separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for clarification Liquid discharge: With centripetal pump under pressure Constructional features: Pressure tight design Design of hood and sediment collector: Sanitary design Type of drive: Flange type motor horizontal

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: TKC 100-06-076 Manufacturer: GEA Westfalia Separator Description: Chamber separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for clarification Liquid discharge: With centripetal pump under pressure Constructional features: Standard design Design of hood and sediment collector: Sanitary design Type of drive: Flange type motor horizontal

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: TDC 260-06-503 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for clarification Liquid discharge: With centripetal pump under pressure Constructional features: Pressure tight design Design of hood and sediment collector: Removable hood Type of drive: Flange type motor

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: TDC 160-16-503 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for clarification with concentrate recycle Liquid discharge: With centripetal pump under pressure Constructional features: Pressure tight design Design of hood and sediment collector: Removable hood Type of drive: Flange type motor

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: TDC 160-06-503 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for clarification Liquid discharge: With centripetal pump under pressure Constructional features: Pressure tight design Design of hood and sediment collector: Removable hood Type of drive: Flange type motor

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: TDC 130-16-503 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for clarification with concentrate recycle Liquid discharge: With centripetal pump under pressure Constructional features: Pressure tight design Design of hood and sediment collector: Removable hood Type of drive: Flange type motor

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: TDC 130-06-503 Manufacturer: GEA Westfalia Separator Description: Nozzle Separator Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list Bowl design: Bowl for clarification Liquid discharge: With centripetal pump under pressure Constructional features: Pressure tight design Design of hood and sediment collector: Removable hood Type of drive: Flange type motor

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: A 610 HGD Manufacturer: Alfa Laval Description: Disk Separators; self-cleaning Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: C 714 HGV Manufacturer: Alfa Laval Description: Disk Separators; self-cleaning Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: C 618 HGV Manufacturer: Alfa Laval Description: Disk Separators; self-cleaning Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: C 614 HGV Manufacturer: Alfa Laval Description: Disk Separators; self-cleaning Equipment: Frame, Bowl, Motor, Hood, Valves, Foundation frame, Tools, Controls, Manual and spare parts list

Request for a quoteResults for

Separating - Import exportNumber of results

774 ProductsCategory

- Knives, industrial (13)

- Oiling - machines and systems (11)

- Measurement - Equipment & Instruments (6)

- Wood veneer - machinery and equipment (3)

- Electric motors and parts (2)

- Recycling - machines and installations (2)

- Filtering equipment and supplies (1)

- Waste sorting - machines and equipment (1)

- Air treatment - equipment and systems (1)

- Magnets (1)

- Castors, swivelling (1)

- Components and parts for small household appliances (1)

- Flame retardant construction materials (1)

- Industrial equipment hire (1)

- Industrial tools (1)