- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- saw blades

Results for

Saw blades - Import export

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

The high noise level at a construction site can damage the health of construction workers and others. Residents near a building site are often suffer for weeks and months due to noise emissions. Since in most cases it is not possible to protect the whole work area of the building site against noise emissions, it must be attempted to make the individual construction machines and devices less noisy. For equipping circular building site saws, AVOLA has developed a special blade-type HM/A/SG = carbide tipping/wolf tooth/silenced. This saw blade has eight serpentine laser incisions in the master blade 8 that reduce drumming of the master blade. At the same time, these laser incisions are distributed in such a way that the master blade still retains the pretension that is needed for the stability of the saw blade when idling and cutting.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

AVOLA Circular saw blade HM/A/PH for cutting polystyrene and wood Special benefits of our patented development: One saw blade for two materials For polystyrene (Styrodur and styrofoam) and wood No jamming and sticking, because the newly developed openings in the master blade ensure sufficient air cooling Even without blade replacement More safety and occupational protection Faster, more effective and environmentally friendly operation

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

As a market leader for circular building site saws and with more than 80 years of experience, we know what is important. With this knowledge, we work continually to keep products up to date, thereby offering the highest-quality, most durable and safest machines.Changes in the machinery directive For improved safety, we have developed a safety hood that has proven to significantly reduce occupational accidents as part of the revision of standard EN 1870-19 prior to the amendment of the Machinery Directive 2006/42/EC. This was awarded the EURO Test Prize of the EU Builder's Trade Associations. Since the new machinery directive went into effect in 2010, all new circular building site saws have been equipped with the newly improved safety hood and other essential safety components and have been delivered exclusively in this version.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Avola building site table saw ZBV 500 S with height and tilt adjustment and safety guard. The new ZBV 500-S is a height and tilt adjustable building site circular saw with a 500 mm saw blade. The ZBV 500-S also enables bevel cuts with a high cutting height on the construction site. Above all, the increasingly used insulating material can be optimally processed in connection with the AVOLA special circular saw blade HM / A / PH (see above).

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Avola GAMA 65 V revolving cross cut / rip cut saw Equipment / scope of supply- Cutting heights 90° / 245 mm - 45° / 164 mm - 30° / 113 mm - Machine table with lateral movement approx. 400 mm with pneumatic brake system - Machine hood with lateral PVC protective curtains - pneumatic clamping cylinder left - right - pneumatic cross-cutting operation using two-hand control - electrical saw blade inclination 90 – 30° - Revolving table 0 - 270° - Laser light for cross-cutting - Saw bla de height adjustment via mechanical stop system with scale - TCT saw blade 650 mm, dust extraction spigots 160 / 125 mm - Drive motor 12 kW – direct motor speed 1/min – 3,000 - Saw blade speed 1/min – 3,000

Request for a quote

ARNTZ GMBH + CO. KG

Germany

The universal band saw blade for all construction and insulation materials of small and large dimensions running on brick band saw machines. The new variable tooth pitch ensures notably low-vibration and quiet sawing processes and assures supreme quietness. The results are clean and smooth cuts of the best quality. Thanks to its long blade life and increased durability, our further developed, precision-ground tooth geometry is particularly convincing in hard building materials: • particularly low vibration and quiet • long blade life in especially precise and smooth cuts The specialist for: • Pore or lightweight concrete • Perforated brick • Porous bricks ("Poroton") • Insulation material

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Stainless steel • Heat resistant steels • Cold and hot working steels • Hardened steel up to 1900 N/mm2 • Nickel based alloys • Aluminium-silicon alloys • Copper-nickel alloys • Titanium and titanium alloys • Exotic, hard to cut alloys

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Induction hardened piston rods • Steels hardened up to 62 HRC • Hard chromium plated materials • Manganiferrous alloyed steels

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Aluminium alloys • Aluminium bronzes • Copper alloys • Sand cast aluminium and cast magnesium • Graphite

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Stainless steel • All-purpose use for steels and non-ferrous metals • Tensile strengths of up to 1400 N/mm2 • Thick walled structurals

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Pure aluminium and aluminium alloys • Solid material and structurals

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Small workshop bandsaws • Common steel qualities and non ferrous metals • Cross sections over approx. 100 mm (4”)

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Large cross-section steel beams • Structurals with residual stress

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Pure aluminium and aluminium alloys • Solid material and structurals • Materials with residual stress and a tendency to become pinched

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Common steel qualities and non ferrous metals • Short-chipping materials • Small structurals with thin walls • Narrow cross sections up to approx. 100 mm (4”) • Contour cutting operations

Request for a quote

ARNTZ GMBH + CO. KG

Germany

For sawing processes using minimal lubrication. Powerful at high cutting speeds and feeds. Engineered for : • Steel beams, profiles and tubes • Mixed cross-sections

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Steel beams, profiles and tubes • Mixed cross-sections

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Structurals with light or medium walls • Short chipping materials • Sheet metal on vertical band saw machines

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • All-purpose use for construction steel, low-alloy steel, cast iron, aluminium, copper and bronze • Solid material in medium and large dimensions

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • hard and tough materials up to 1700 N/mm2 tensile strength • Stainless steel • heat resistant duplex steel • nickel based alloys • aluminium alloys • titanium bades alloys

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Steels of the highest tensile strength • Long chipping materials • Stainless steel • Titanium based alloys • Nickel based alloys • Special bronzes

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Titanium alloys • Metals with high residual stress • Stainless steels • Special alloys • Abrasive non-ferrous metals and graphite

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

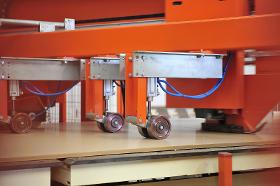

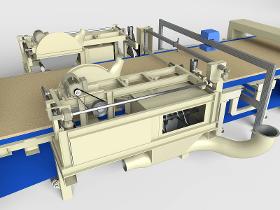

The boards are cut o the endless mat in the saw section. The process becomes a discontinuous one that is characterised by cycle times from this point on. The saw section includes the board edge-trimming and saw units. The board is cut by saws that are positioned at right angles to the endless board and that cut straight proportionally to the feed of the press. It is possible to change the tools without interruption to the production process depending on the number of individual units. longitudinal edge trimming device 2 edge-trimming units – no production possible while tools are being changed 2 edge-trimming units with the option for retrotting additional units 4 edge-trimming units for interruption-free changing of the saw blades Bevelling of the endless board after trimming Multi-diagonalsaw Up to two saw beams each with two units, i.e. four saws maximum Number of saws depending on the feed and desired board length

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The mat trimming saw cuts the precompressed mat precisely to the width required. Two motor-adjustable saws, one each on either side of the belt, cut the bre mat to the dened width. The trimming waste is disintegrated and may be recycled to the production process. Features, function Modular design Motor-adjusted saw blades incl. distance measurement Max. trimming waste of 420 mm on either side Max. mat height ex prepress 360 mm Integrated hogger including extraction stub to remove the trimming waste Extraction stub at the saw blade

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The trimming saw is installed downstream of the last surface-layer mat former, cutting the strand mat precisely to the required width. Two motor-adjustable saws, one each located on either side of the belt, cut the strand mat to the dened width. The trimming waste is discharged through a hopper and recycled to the mat former bins. Features Motor-adjusted saw blades incl. distance measurement Movable mat edge retainers to ensure high-quality cuts Lateral pressure rollers ex saw compact and smoothen the mat edge Movable extraction system adjustable to mat thickness Advantages Recipe-related adjustment of all adjustable axes Eective strand extraction

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp's continuous saws are a tried-and-tested solution for plants with highest outputs. The saw throughput does not depend on the number of cuts and is therefore superior to other cutting solutions, particularly for large master boards. Continuous saws also permit in-line quality grading. This means that the combined sanding and saw line is able to deliver sorted stacks of nished boards from the master boards in a single stage of work. This allows investment and operating costs to be minimised. The cut-to-size saws may be combined in-line with a sanding machine or set up separately just as a cutting system Features and functions Continuous saws for longitudinal and horizontal cuts Scoring unit and main saw blade for top-quality edges Reliable guiding of the board using chains and/or rollers to ensure accurate cutting Trimming of the edges directly by the tool, no additional conveyors and follow-up work required

Request for a quote

C. AUGUST HÜCHELBACH GMBH & CO. KG

Germany

Our high-grade friction saw blades, MALTESERKREUZ BRAND, are used among other things for cutting profiles, thin-walled tubes, gratings etc.. It is characterised by its high abrasion resistance and a long life-time. Basic version in material 80 CrV 2 (material-no. 1.2235) chrom-vanadium-steel, plain hardened, hollow or surface ground, tensioned and straightened. Tooth geometry: Tooth Trennjäger; pointed toothing Standard Dimension: 400 x 3,0 mm 240 teeth 450 x 3,0 mm 240 teeth 520 x 3,0 mm 300 teeth 520 x 4,0 mm 300 teeth 550 x 4,0 mm 300 teeth 600 x 4,0 mm 300 teeth 700 x 5,0 mm 300 teeth 1000 x 8,0 mm 350 teeth

Request for a quote

C. AUGUST HÜCHELBACH GMBH & CO. KG

Germany

Our Circular Saw Blades, MALTESERKREUZ Brand, are manufactured from high-grade raw materials. Modern equipment operated by highly skilled staff guarantee high-quality products, which made us so successful locally and worldwide. Important tooth shapes: DIN : KV = Shape A DIN : NV = Shape B DIN : NV 5° = Shape C DIN : AV = Shape D DIN : KV 5° = Shape E Sizes from Ø 400 mm – Ø 1500 mm Smaller or bigger sizes and extra requirements are available on request.

Request for a quote

CARL RÖNTGEN GMBH

Germany

Our narrow bandsaw blades are produced in coils and ready for use. Here, we use the most common tooth form in the wood industry NV. We sell the narrow bandsaw blades as: toothed, toothed and set, toothed, set and sharpened. We offer the following pitches: 6 mm, 7 mm, 8 mm, 9 mm, 10 mm, 12 mm Below you can find the standard and semi-standard production program. (We can also produce other sizes. In this case, please contact us directly.) Standard (mm) Semistandard (mm) 10 x 0,6 10 x 0,4 | 10 x 0,5 10 x 0,6 12 x 0,4 | 12 x 0,5 15 x 0,6 15 x 0,4 | 15 x 0,5 | 15 x 0,7 20 x 0,7 20 x 0,4 | 20 x 0,5 | 20 x 0,6 25 x 0,7 25 x 0,4 | 25 x 0,5 | 25 x 0,6 | 25 x 0,8 30 x 0,7 30 x 0,6 | 30 x 0,8 35 x 0,8 – 40 x 0,8 –

Request for a quoteResults for

Saw blades - Import exportNumber of results

32 ProductsCompany type