- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rolling

Results for

Rolling - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

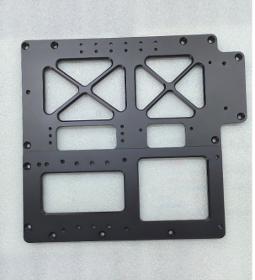

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

The economic adjustment to small batch sizes, we meet with our turned parts for the direct assembly in plastics and die-cast products. Any thread forms such as, thread-tapping (DIN7500), thread cutting (DIN 7513-7516) or KTG for direct screw in plastics are realized cost-effectively. Advantage is the elimination of high tooling costs, since no counter-thread in the workpiece (eg threaded inserts, nuts, etc.) is required because the direct assembly takes place directly into the workpiece. Only a given tube is required in order to screw it directly. Our turned parts replace previously cold formed parts used (so-called multi-station presses) which require high output volumes in order to achieve a reasonable price parts.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

The market for an ever-increasing array of consumer electronics parts is made possible by continuing innovation in integrated circuitry, new software applications and the exceptional properties of industrial aluminum, such as its light weight, high formability, superior heat dissipation, electrical conductivity, high corrosion resistance and attractive surface properties. Whether it is smartphones, tablets, laptops or flat screen TVs, aluminum is an integral component in the design, development and production of the latest personal devices and in-home entertainment systems. Novelis is leading the way in producing customized, premium flat-rolled aluminum for many consumer electronics parts and products, including aluminum enclosures and aluminum cases. Our aluminum products, developed according to customer specifications, are supplied in coil or sheet form, then slit or cut to length by third-party distributors or customers themselves.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis has created the first flat-rolled, aluminium-intensive electric vehicle battery enclosure designed for mass production vehicles. Learn more by downloading the product fact sheet. By utilizing Novelis’ highly-formable alloys, the battery enclosure provides automakers the ability to achieve deep drawn, complex shapes tailored to specific vehicle design requirements. The lightweight, high-strength material can help extend range, allowing vehicles to go 6-10 percent further on a single charge. With safety as a top priority, Novelis conducted extensive testing simulations to ensure its innovative, high-strength materials will protect batteries from road debris and vehicle crashes.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis products are renowned for their use in building and construction, but our aluminum also can help ensure the efficiency of buildings and maintain the comfort of those inside. Novelis aluminum is flexible but strong, stylish but practical – characteristics that make it ideal for construction of roller shutters, sunbreakers and windows. Exposed to the harshest conditions, our pre-painted rolled aluminum can withstand mother nature’s worst yet retain its ease of use and like-new aesthetics for years to come. Novelis SP80 is the name of a particularly abrasion-resistant paint system for roller shutter slats based on polyamide-treated premium polyurethane.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Our pre-painted products are specially made for the requirements of aluminum shutters, sunbreakers and windows, protecting not just exteriors, but interiors as well. At Novelis, we collaborate with our clients to bring their visions to life, enhanced by aluminum’s practical benefits from aesthetics to cost-effectiveness that the material provides in these building and construction applications. Outside, rolling aluminum shutters, sunbreakers and windows provide a barrier to weather. In oceanfront and surrounding areas, they can also serve as protection from high winds and storms that can break windows and damage property. In many cases, the protection these aluminum window shutters afford can reduce insurance premiums in such storm-prone zones. Inside, these structures can provide privacy, sound insulation and light-level control, making for a better interior environment, whether the building is commercial or residential.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis specialty aluminum offers a range of possibilities for interior and decorative designs. The light weight and flexibility make it ideal for use in aluminum ceiling panels. Smooth or perforated, Novelis pre-painted products can be used for aluminum ceiling panels, grid ceilings, long panel cassettes, lamp grid elements, substructure partitions, aluminum decorative panels and support rails. The aluminum also can be combined with other materials to achieve excellent acoustic absorbance. With the modular production of aluminum ceiling tiles, if there’s ever any damage, only that area requires replacement, making maintenance simple and more cost-effective. With the versatility of aluminum, interior spaces can be as visually impressive as the exterior. Novelis pre-painted and anodized aluminum can make rooms better from the top down, providing options to enhance ceilings in a room, as well as the furniture to fill it.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

In the aerospace industry we specialize in the production of rolled aluminum plate and sheet materials for fuselage and wing structure components according to standard or customized specifications. The aerospace industry is building new aircraft to accommodate a growing number of air passengers and to replace older, less efficient planes with newer, more fuel-efficient models. Aluminum offers a high strength-to-weight ratio, energy efficiency, and high tolerance to extreme temperatures- making it an ideal material for the manufacturing of aircraft. It can also be recycled repeatedly, making it a good choice as manufacturers pursue sustainability initiatives. We have introduced new low-density alloys that represent an innovative step forward for aluminum in aerospace. Weight-savings from these new alloys translate into fuel efficiency and lower operating costs for the airline industry.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis is the global leader in rolled aluminum products and aluminum beverage can recycling. Our technical competence and innovation have made us a development partner chosen by leading companies from the automotive, building, printing and packaging industries, among others. With its customer orientation and strong industrial performance, Novelis plays a crucial part in shaping products for the future. The aluminium content means that there is only slight thermal length variation, just like with metal tubes. In addition, the tubes become completely oxygen-impermeable, which is indispensable when connecting radiators, for example. Using state-of-art production facilities and experienced specialists, Novelis ensures top quality in the manufacture of its products – across the entire production process, from casting and processing the ingots via hot and cold rolling, to packaging.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

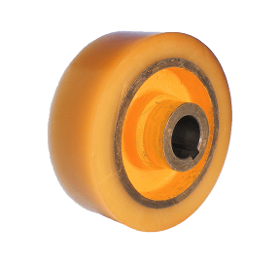

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design in smooth or grooved form and the most suitable degree of hardness must be determined by the customer. Weinig rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core mounting holes are designed as a keyway or with three side holes.The Weinig rollers are mainly coated with the elastomer Vulkollan® patented by Bayer. We would be happy to advise you by telephone or at your location regarding high-quality and cost-effective design of pressure and feed rollers.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Harbs rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. We would be pleased to advise you on which harbs rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Gubisch rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core receiving hole is designed with a feather keyway. We would be pleased to advise you on which gubisch rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

GSW SCHWABE AG

Germany

Roll Feeds with servo drive They revolutionized the advancement of strip material in the early 1980’s. However, Air Feeds became far from obsolete over 90 different GSWModels show that even today demands for costs, material geometry or composition as well as mounting situations more than justify this technology.

Request for a quote

GSW SCHWABE AG

Germany

High feeding accuracy, quick cycles and simple operation Servo feeding in compact design with maintenancefree AC servo motor Fits just about any press +/ 0,025 mm feeding accuracy through incremental servo encoder Lightweight rollers with special hard chrome layer Mechanical pilot release Sturdy steel plate bolton design Height adjustment via threaded spindle Catenary rolls and edge guides at machine entrance Stock guides at exit Highperformance control with good functionality; with remote control for setup on 3,5 m cablel 24 V DC proximity switch adjustable piloting lever to be mounted to press pneumatic pilot release

Request for a quote

GSW SCHWABE AG

Germany

With threephase servo drive sized according to job requirements Machine body in sturdy clean steel plate design Rollers made of highquality 63 RW tool steel, hardened and polished Pneumatic pilot release with parallel lift of upper roller, guided on gear rack Entry catenary rolls Manual edge guides Simple programming of even complex feeding cycles, Display in cleartext Manual functions for setup such as creep speed, jog mode, single feedtolength Simple memory and recall of job programs for quick changeover Mounting bracket with height adjustment via spindle or hydraulic handpump (optional motorized) Hard chromed or polyurethane coated rollers (optional with Topochrome coating for highgrip feeding) Measuring wheel system for highest feeding accuracy Stroke limitation for faster piloting Fine adjustment of upper roller and strip guiding device for thin stocks (starting at 0,1 mm thickness) Central edgeguides with hand wheel

Request for a quote

GSW SCHWABE AG

Germany

GSW Roll Feeds Precise and fast positioning with lasting performance. Built with the attributes of parallel adjustment of the top roll, highprecision roll guiding and mechanical stroke limitation for fastest cycles. In combination with most modern motion control systems our Roll Feeds feature a highly reliable production support with dynamic feeding performance of max 30 m/s² acceleration. For smaller crosssections we offer the HSseries Roll Feed model This dynamic and costeffective solution makes the upgrade from gripper feeds to the much more flexible roll feed technology affordable. from coil up to 2000 mm material width and up to 8 mm thickness max crosssection approx. 2000 x 5 mm Vmax approx. 80 200 m/min max cycles with pilot release approx. 100 220 SPM from plate or bar up to 20 mm material thickness

Request for a quote

F.E.S. GMBH

Germany

Automatic Precoat Filter are used for the cleaning of contaminated cutting fluids in metal processing and rolling mill applications. Clean cutting fluids lead to longer tool life, improved surface quality of workpieces or rolled goods, and efficient heat dissipation at the processing or forming point. Advantages: Fully automatic operation Excellent filtration results Compact size Low maintenance requirements Full-flow filtration Dry cake discharge with minimal carryover of cutting fluid No fleece consumption Maximum lifespan of cutting fluid Operating Principle: The cleaned cutting fluid is supplied to the filter system pump (1) from the clean tank (2) of the processing machine. The contaminated cutting fluid is introduced into the dirt tank (3) of the cake filtration system through inlet channels or lifting stations. The internal processing of the system consists of four steps: “Cake Formation,” “Filtration,” “Regeneration,” and “Sludge Treatment.”

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ROLKO KOHLGRÜBER GMBH

Germany

We offer high-quality design wheels for sports and children's wheelchairs and other rehabilitation devices for the best driving comfort, combined with an attractive design. In our range you will find modern steering wheels with light aluminum rims or ultra-light carbon rims as well as vulcanised solid rubber tires or shiny polyurethane tyres. We also have skate wheels in various sizes and designs, with integrated LEDs if required. In addition to our standard range, we also manufacture customer-specific wheels with our many years of know-how in the industry, not only according to the wishes of our customers, but also according to the latest European norms and quality standards. Do you have any questions about our products or would you like to request an offer? Just contact us. We have the right wheel for almost every application!

Request for a quote

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

synthetic filter media progressive construction of filter layer thermally bonded individual pads or filter rolls available small installation depth low acquisition costs

Request for a quote

BAUER GMBH

Germany

-sturdy steel construction -ideally situated loading centre of gravity -can be emptied at any height by cable -operated from the driver‘s seat -body wall with reinforced edging -sturdy frame with fork sleeves -can be secured to prevent slipping and unintentional emptying -wheels can be fitted later -Surface spray painted or hot-dip galvanized -Volume (approx. in m³): 0,15 / 0,30 / 0,60 / 0,90 / 1,20 / 1,70 / 2,10 -Load capacity: 750 - 1500 kg Accessories: -2 swivel + 2 fixed polyamide castors Ø 180 mm, one swivel castor with brake construction height 220 mm -galvanized lid, can be opened from both sides -welding, oil- and watertight -trailer coupling and towing bar

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

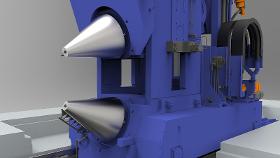

With the ring rolling mill Siempelkamp completes its range of products for the manufacture of rings. From forging the pre-forms to manufacturing the ring blanks to ring rolling, we supply everything from a single source. Siempelkamp’s ring rolling mill manufactures seamless rings made of steel and special materials such as nickel-base, titanium, or aluminium alloys using maximum radial and axial pressing forces. The radial pressing force is hydraulically generated and applied to the part via a mandrel roll. Radial rolling is carried out by reducing the roll gap between the driven external roller and the mandrel roll. The axial pressing force is also hydraulically generated and applied to the part via the upper axial roller. Axial rolling is carried out by means of the vertical forward feed of the upper axial roller. A centring device provides for the correct position of the ring during the rolling process.

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Application areas for straightening presses include the sheet metal processing industry. Here, this type of press is used for the straightening of semi-nished products, such as the levelling of uneven sheet metal and slab surfaces, which are used in subsequent processes. In addition to high straightening accuracy, Siempelkamp straightening presses provide a broad straightening spectrum and high exibility in the further processing of sheet metal. For materials with a tensile strength of 1,300 N/mm2, sheet metal with a thickness of approx. 300 mm can be processed To do so, the presses are equipped with one or several straightening rams which can be operated together or individually. The pressing force needed for straightening is applied across the entire press width. Sheet metal can be straightened by cold or warm forming with sheet temperatures of up to 600°C.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

As the leading provider of metal forming presses we are setting the standard worldwide. Our expertise in plant engineering and process technology is unique. This is because the individual performance features from the design to the startup of the equipment create a coherent and complete solution from a single source. Our hydraulic presses for metal forming are at home in cold and hot forming. From turbine disks for aircraft to pipeline pipes in the oil and gas industry to longitudinal beams in trucks: In our key industries of automotive, energy, rail and aerospace, we offer the right solution for every product. We supply not only the press, but also the associated process technology. Our range of services includes forging, thick sheet metal forming, raw forming, sheet metal forming and ring rolling. Our special systems for metal forming offer the perfect balance between the use of standard components and a custom-made design.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Roller transports, if required with workpiece transposition from one to two lanes, accumulation and disc roller conveyors or bar transport units complement our portfolio of continuous conveyor systems. VEN TRANS system techniques enable tailor-made workpiece conveying and handling concepts. We create Our solutions take into account

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you idler pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you drive pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Carrying rollers made of steel and HDPE Carrying rollers suitable in both heavy and light application conditions bulk goods and unit load rollers also available for delivery with cogs and conical rollers delivery of small quantities possible

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

close tolerances and longitudinally welded carrying roller tubes made of S235JR steel in accordance with DIN 2458; deep drawn steel bearing retainers with calibrated bearing seats pressed in from the side and circularly welded, material thickness min. s = 2.00 mm; RAL 3000 red powder coated sheath, coating thickness min. 60 U; 20 mm Ø round steel in accordance with ISO h9; single row radial steel ball bearings in accordance with DIN625 type 6204 with suitable grease filling and cover plates on both sides made of sheet steel C3 bearing clearance. The calculated service life of the ball bearings, assuming belt speed 2m/sec. delivery capacity 200 t/he bulk weight 0.75 t/m³ temperature range 0° C 50° C is 30,000 hours. Steel circlip in accordance with DIN 471 Sealing using double labyrinth seal, incl. suitable grease filling, galvanized, sheet steel sealing cap and plastic rain cap

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The carrying frame prevents belt misalignment and guarantees protection of the belt edges. As the carrying frames only function efficiently when the drum casing is clean, they are equipped and delivered with dirt repellent 60° shore soft rubber. Our carrying frames can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quoteResults for

Rolling - Import exportNumber of results

70 ProductsCompany type

Category

- Steel, special (26)

- Rolling machines (7)

- Aluminium sheets and bands (4)

- Forming - steels and metals (3)

- Measurement - Equipment & Instruments (3)

- Metal straightening machines (3)

- Shutters (2)

- Components and parts for small household appliances (2)

- Industrial equipment hire (2)

- Industrial tools (2)

- Import-export - paper and cardboard (1)

- Containers, metal (1)

- Rolling mills - ferrous metals (1)

- Filtering equipment and supplies (1)

- Paper & Cardboard - Finished Products (1)