- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- push push

Results for

Push push - Import export

N&H TECHNOLOGY GMBH

Germany

Our range of vandal resistant pushbuttons is very wide to offer you the best possible choice. With our handy configurator you can quickly and easily put together the perfect pushbutton for your needs and request it directly. New: an individual engraving of the push-button cover is possible for push-buttons of the S1AGQ series with mounting diameters of 16mm, 19mm and 22mm. In addition to the individual configuration of our three basic series, we also offer you the option of manufacturing completely customized pushbuttons in individual colors, engravings and adapted technical specifications. Simply send us your desired requirements by e-mail. Our engineers will configure your suitable pushbutton and send you an offer. If you have any questions, we will of course be happy to answer them and provide you with comprehensive advice on selecting the right pushbutton for your application.

Request for a quote

IGUS® GMBH

Germany

EasyChains® are available in two versions. In the "E" version the cable is simply laid from the outside, and in the "Z" version from the inside. The shortened installation time is one of the main features of the Easy Chain® chains. Their elastic and rugged material igumid NB offers even more reasons for application: Optimum elasticity, UL94-V2 Classification and excellent suitability for clean rooms. Their one-piece design makes EasyChain® especially attractive in price. Due to the lower rigidity of the material, the EasyChain® is not suitable for applications with very high load. New: Now as ESD option Easy Chain® as ESD Overview for easy chain® advantages Further information Series E03 Inner height hi: 5 mm Inner widths Bi: 5 - 10 mm bending radii R: 10 - 28 mm Pitch: 10 mm E-Chain®, to be filled in the outer radius Series E04 Inner height hi: 7 mm Inner width Bi: 7 mm Bending radii R: 15 - 48 mm Pitch: 16.7 mm E-Chain®, to be filled in the outer radius Series E045 Inner height hi: 9.4 mm Inner width Bi: 16 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the outer radius Series E045.2 Innerheight hi: 9,4 mm inner width Bi: 7+7 mm | 9+9 mm Bending radii R: 18 - 38 mm Pitch; 13 mm E-Chain®, to be filled in the outer radius Series E045.3 Inner height hi: 9,4 mm Inner width Bi: 9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the outer radius Series E06 Inner height hi: 10,5 mm Inner widths Bi: 10 - 16 mm bending radii R: 18 - 38 mm Pitch: 20 mm E-Chain®, to be filled in the outer radius Series E065 Inner height hi: 11,3 mm Inner width Bi: 16 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E065.2 Inner height hi: 11,3 mm Inner width Bi: 9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E065.3 Inner height hi: 11,3 mm Inner width Bi: 9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E065.4 Inner height hi: 11,3 mm Inner width Bi: 9+9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E08 Inner height hi: 14,6 mm Inner widths Bi: 10 - 50 mm bending radii R: 28 - 48 mm Pitch: 20 mm E-Chain®, to be filled in the outer radius Series E14 Inner height hi: 19 mm Inner widths Bi: 15 - 50 mm bending radii R: 28 - 125 mm Pitch: 30,5 mm E-Chain®, to be filled in the outer radius Series E200 Inner height hi: 24.3 mm Inner width Bi: 57 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the outer radius Series E200.2 Inner height hi: 24.3 mm Inner widths Bi: 37+37/50+50 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the outer radius Series E16 Inner height hi: 32 mm Inner widths Bi: 23 - 100 mm bending radii R: 60 - 100 mm Pitch: 30,5 mm E-Chain®, to be filled in the outer radius Series E26 Inner height hi: 36.5 mm Inner width Bi: 75 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the outer radius Series E26.2 Inner height hi: 37.1 mm Inner width Bi: 48+48 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the outer radius Series E26.3 Inner height hi: 37.1 mm Inner width Bi: 47+48+47 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the outer radius Series E300 Inner height hi: 48,5 mm Inner width Bi: 75 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the outer radius Series E300.2 Inner height hi: 48.5 mm Inner width Bi: 48+48 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the outer radius Series E300.3 Inner height hi: 48.5 mm Inner width Bi: 47+46+47 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the outer radius Series Z045 Inner height hi: 9.4 mm Inner width Bi: 16 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the inner radius Series Z045.2 Inner height hi: 9,4 mm Inner width Bi: 7+7 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the inner radius Series Z06 Inner height hi: 10,5 mm Inner widths Bi: 10 - 16 mm bending radii R: 18 - 38 mm Pitch: 20 mm E-Chain®, to be filled in the inner radius Series Z065.3 Inner height hi: 11.3 mm Inner widths Bi: 9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the inner radius Series Z08 Inner height hi: 14,7 mm Inner widths Bi: 10 - 50 mm bending radii R: 28 - 48 mm Pitch: 20 mm E-Chain®, to be filled in the inner radius Series Z14 Inner height hi: 19 mm Inner widths Bi: 15 - 50 mm bending radii R: 28 - 125 mm Pitch: 30,5 mm E-Chain®, to be filled in the inner radius Series Z200 Inner height hi: 24.3 mm Inner width Bi: 57 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the inner radius Series Z200.2 Inner height hi: 24.3 mm Inner widths Bi: 37+37/50+50 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the inner radius Series Z16 Inner height hi: 32 mm Inner widths Bi: 23 - 100 mm bending radii R: 40 - 125 mm Pitch: 30,5 mm E-Chain®, to be filled in the inner radius Series Z26 Inner height hi: 36.5 mm Inner width Bi: 75 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the inner radius Series Z26.2 Inner height hi: 37.1 mm Inner width Bi: 48+48 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the inner radius Series Z26.3 Inner height hi: 37.1 mm Inner width Bi: 47+48+47 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the inner radius Series Z300 Inner height hi: 48,5 mm Inner width Bi: 75 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the inner radius Series Z300.2 Inner height hi: 48.5 mm Inner width Bi: 48+48 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the inner radius Series Z300.3 Inner height hi: 48.5 mm Inner width Bi: 47+46+47 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the inner radius Certificate IPA: standard material ISO Class 2 according to ISO 14644-1, v = 1 m/s UL94-V2 classification Rotary movement possible Easy Chain® with special material igumid ESD as electrically conductive ESD/TEX option available on request EasyChains® are available in two versions. In the "E" version the cable is simply laid from the outside, and in the "Z" version from the inside. The shortened installation time is one of the main features of the Easy Chain® chains. Their elastic and rugged material igumid NB offers even more reasons for application: Optimum elasticity, UL94-V2 Classification and excellent suitability for clean rooms. Their one-piece design makes EasyChain® especially attractive in price. Due to the lower rigidity of the material, the EasyChain® is not suitable for applications with very high load. New: Now as ESD option Easy Chain® as ESD Overview for easy chain® advantages Further information Series E03 Inner height hi: 5 mm Inner widths Bi: 5 - 10 mm bending radii R: 10 - 28 mm Pitch: 10 mm E-Chain®, to be filled in the outer radius Series E04 Inner height hi: 7 mm Inner width Bi: 7 mm Bending radii R: 15 - 48 mm Pitch: 16.7 mm E-Chain®, to be filled in the outer radius Series E045 Inner height hi: 9.4 mm Inner width Bi: 16 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the outer radius Series E045.2 Innerheight hi: 9,4 mm inner width Bi: 7+7 mm | 9+9 mm Bending radii R: 18 - 38 mm Pitch; 13 mm E-Chain®, to be filled in the outer radius Series E045.3 Inner height hi: 9,4 mm Inner width Bi: 9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the outer radius Series E06 Inner height hi: 10,5 mm Inner widths Bi: 10 - 16 mm bending radii R: 18 - 38 mm Pitch: 20 mm E-Chain®, to be filled in the outer radius Series E065 Inner height hi: 11,3 mm Inner width Bi: 16 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E065.2 Inner height hi: 11,3 mm Inner width Bi: 9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E065.3 Inner height hi: 11,3 mm Inner width Bi: 9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E065.4 Inner height hi: 11,3 mm Inner width Bi: 9+9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the outer radius Series E08 Inner height hi: 14,6 mm Inner widths Bi: 10 - 50 mm bending radii R: 28 - 48 mm Pitch: 20 mm E-Chain®, to be filled in the outer radius Series E14 Inner height hi: 19 mm Inner widths Bi: 15 - 50 mm bending radii R: 28 - 125 mm Pitch: 30,5 mm E-Chain®, to be filled in the outer radius Series E200 Inner height hi: 24.3 mm Inner width Bi: 57 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the outer radius Series E200.2 Inner height hi: 24.3 mm Inner widths Bi: 37+37/50+50 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the outer radius Series E16 Inner height hi: 32 mm Inner widths Bi: 23 - 100 mm bending radii R: 60 - 100 mm Pitch: 30,5 mm E-Chain®, to be filled in the outer radius Series E26 Inner height hi: 36.5 mm Inner width Bi: 75 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the outer radius Series E26.2 Inner height hi: 37.1 mm Inner width Bi: 48+48 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the outer radius Series E26.3 Inner height hi: 37.1 mm Inner width Bi: 47+48+47 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the outer radius Series E300 Inner height hi: 48,5 mm Inner width Bi: 75 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the outer radius Series E300.2 Inner height hi: 48.5 mm Inner width Bi: 48+48 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the outer radius Series E300.3 Inner height hi: 48.5 mm Inner width Bi: 47+46+47 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the outer radius Series Z045 Inner height hi: 9.4 mm Inner width Bi: 16 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the inner radius Series Z045.2 Inner height hi: 9,4 mm Inner width Bi: 7+7 mm Bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, to be filled in the inner radius Series Z06 Inner height hi: 10,5 mm Inner widths Bi: 10 - 16 mm bending radii R: 18 - 38 mm Pitch: 20 mm E-Chain®, to be filled in the inner radius Series Z065.3 Inner height hi: 11.3 mm Inner widths Bi: 9+9+9 mm Bending radii R: 18 - 38 mm Pitch: 15 mm E-Chain®, to be filled in the inner radius Series Z08 Inner height hi: 14,7 mm Inner widths Bi: 10 - 50 mm bending radii R: 28 - 48 mm Pitch: 20 mm E-Chain®, to be filled in the inner radius Series Z14 Inner height hi: 19 mm Inner widths Bi: 15 - 50 mm bending radii R: 28 - 125 mm Pitch: 30,5 mm E-Chain®, to be filled in the inner radius Series Z200 Inner height hi: 24.3 mm Inner width Bi: 57 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the inner radius Series Z200.2 Inner height hi: 24.3 mm Inner widths Bi: 37+37/50+50 mm Bending radii R: 55 - 200 mm Pitch: 46 mm E-Chain®, to be filled in the inner radius Series Z16 Inner height hi: 32 mm Inner widths Bi: 23 - 100 mm bending radii R: 40 - 125 mm Pitch: 30,5 mm E-Chain®, to be filled in the inner radius Series Z26 Inner height hi: 36.5 mm Inner width Bi: 75 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the inner radius Series Z26.2 Inner height hi: 37.1 mm Inner width Bi: 48+48 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the inner radius Series Z26.3 Inner height hi: 37.1 mm Inner width Bi: 47+48+47 mm Bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, to be filled in the inner radius Series Z300 Inner height hi: 48,5 mm Inner width Bi: 75 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the inner radius Series Z300.2 Inner height hi: 48.5 mm Inner width Bi: 48+48 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the inner radius Series Z300.3 Inner height hi: 48.5 mm Inner width Bi: 47+46+47 mm Bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, to be filled in the inner radius E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining, separating and filling of the Easy Chain®. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. Easy Chain® Easy Chain: "E" and "Z" makes it "Easy" Easily fillable from the inside (Z version) and outside (E version) Quicker filling, access to cables without opening or closing of the lids Can be put together or taken apart at "any point" Cost-effective, one-piece chain Dirt-proof outer contour Mounting brackets with integrated strain relief available Limited torsional movement possible Available with interior separation (many types) Flammability class UL94-V2 Suitable for clean room applications Typical industrial sectors and applications General machinery Clean room application Electronic equipment Office furniture Vending machines Packaging machines Certificate IPA: standard material ISO Class 2 according to ISO 14644-1, v = 1 m/s UL94-V2 classification Rotary movement possible Easy Chain® with special material igumid ESD as electrically conductive ESD/TEX option available on request

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

Due to their porous structure, VYON® and GURON® are ideal for sound insulation, as they enable sound attenuation of up to 30 dBA. Silencer Noise is dangerous to health. That is why noise reduction is an important task in the area of occupational safety. Due to their porous structure, VYON® and GURON® are ideal for sound insulation, as they enable sound attenuation of up to 30 dBA. In addition, VYON® silencers are also suitable for ventilation and filtration. Connection size: 10 mm (push-in silencer) Ø mm: 15.5 +- 0.5 mm Length of sintered body with collar: 31 +-1.5 mm Total length including thread: 57.5 +3 mm

Request for a quote

JUNIE - JUL. NIEDERDRENK GMBH & CO. KG

Germany

2960 pressure cylinder, ø19 mm, 30 mm length, 12 mm hub, keyed different, cylindre brass nickel plated, fixing plate and body metall nickel plated, 2 keys, 1 rose brass nickel plated

Request for a quote

JUNIE - JUL. NIEDERDRENK GMBH & CO. KG

Germany

2960 pressure cylinder, ø19 mm, 23,5 mm length, 12 mm hub, keyed different, cylindre brass nickel plated, fixing plate and body metall nickel plated, 2 keys, 1 rose brass nickel plated

Request for a quote

JUNIE - JUL. NIEDERDRENK GMBH & CO. KG

Germany

8574 FURORE pressure cylinders with mouting plated, ø22 mm, 13 mm hub, metal nickel plated, for door thickness up to 26 mm, without cylinder core, accessory: 1 rose nickel plated and 1 brass sleeve

Request for a quote

JUNIE - JUL. NIEDERDRENK GMBH & CO. KG

Germany

Plus Soft-Close / Push-Open Adapter, colour grey, 37 mm row of hole

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The innovative LAWECO CHAIN-LINE lifting platform technology unites all advantages of belts and spindles. Mechanically driven by a push-chain, this technology achieves maximum performances without the use of hydraulic oil. Due to a particularly harmonious motion sequence and the excellent load change behaviour in each lift position, the CHAIN-LINE is the preferred solution for designers who place an extremely high value on efficiency and precision for their area of responsibility. Unsurpassed precision LAWECO push-chain lifting platforms convince with a load behaviour and maximum positioning precision which were almost unachievable in the past. Unrestricted availability Almost maintenance free, the robust and low failure construction permits fast component replacement. Safety for the environment and employees The intelligent design does without hydraulic oil. Optional contact rails and bellows increase safety.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

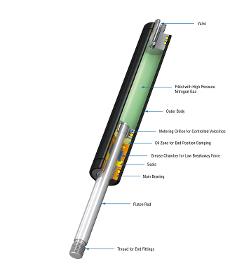

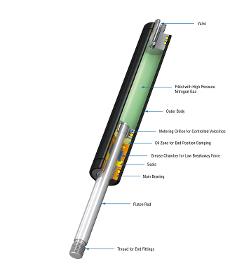

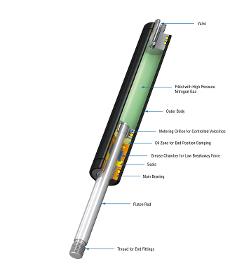

Valve Technology Force range max. 5,000 N Stroke - mm Cover two differing force ranges: Tandem push type gas springs by ACE are maintenance-free and ready-to-install with two pressure tubes with different extension forces and progression curves. With this type of gas spring you cover the different force ranges between the start and end of an application. These force ranges are adjusted and compliment each other, designed individually for the relevant application by the free of charge ACE calculation service, then are specifically manufactured adjusted precisely to the required dynamics of the application. The customer specific systems, for which there are many fitting parts, are specifically suitable for heavy loads with large opening angle and can also be delivered in stainless steel versions.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Valve Technology, Stainless Steel Force range max. 180 N Stroke 20 mm Protection against corrosion and superior optics for even more sophisticated requirements: Based on ACE's industrial gas push type springs GS-8 to 40 made of steel, these models combine all advantages of stainless steel: they look great and are rust free. They are filled with food-grade oil as standard, which conforms to the requirements of FDA 21 CFR 178.3570. These ACE gas push type springs do not only look good, they also are available in various stroke lengths and possible extension forces. A comprehensive range of accessories in stainless steel guarantees easy assembly and a broad range of uses.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Valve Technology, Stainless Steel Force range max. 100 N Stroke 20 mm Protection against corrosion and superior optics for even more sophisticated requirements: Based on ACE's industrial gas push type springs GS-8 to 40 made of steel, these models combine all advantages of stainless steel: they look great and are rust free. They are filled with food-grade oil as standard, which conforms to the requirements of FDA 21 CFR 178.3570. These ACE gas push type springs do not only look good, they also are available in various stroke lengths and possible extension forces. A comprehensive range of accessories in stainless steel guarantees easy assembly and a broad range of uses.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Valve Technology, Stainless Steel Force range max. 100 N Stroke 20 mm Protection against corrosion and superior optics for even more sophisticated requirements: Based on ACE's industrial gas push type springs GS-8 to 40 made of steel, these models combine all advantages of stainless steel: they look great and are rust free. They are filled with food-grade oil as standard, which conforms to the requirements of FDA 21 CFR 178.3570. These ACE gas push type springs do not only look good, they also are available in various stroke lengths and possible extension forces. A comprehensive range of accessories in stainless steel guarantees easy assembly and a broad range of uses.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

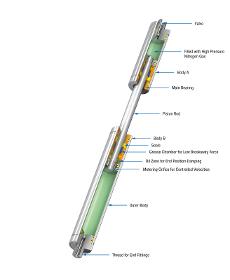

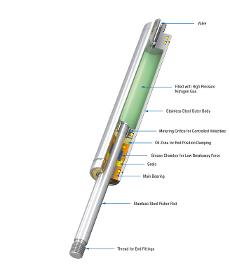

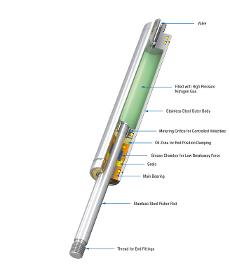

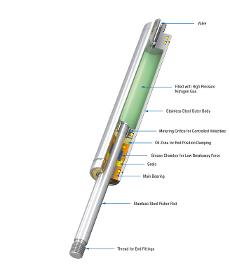

Valve Technology Force range max. 180 N Stroke 20 mm Universal and tailor made: ACE industrial gas push type springs of the NEWTONLINE family offer perfect support of muscle power with forces from 10 to 13,000 N with body diameter of 8 to 70 mm. With their high quality features the NEWTONLINE gas springs form the industry standard. These durable and sealed systems are ready for installation, maintenance-free and filled with pressurised nitrogen gas. They are supplied filled according to individual customer pressure requirements and maybe adjusted later by use of the inbuilt valve. The free of charge ACE calculation service designs the gas springs with mounting points specifically for the particular application. A variety of additional components makes assembly even easier and allows universal application of the gas springs.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Valve Technology Force range max. 100 N Stroke 20 mm Universal and tailor made: ACE industrial gas push type springs of the NEWTONLINE family offer perfect support of muscle power with forces from 10 to 13,000 N with body diameter of 8 to 70 mm. With their high quality features the NEWTONLINE gas springs form the industry standard. These durable and sealed systems are ready for installation, maintenance-free and filled with pressurised nitrogen gas. They are supplied filled according to individual customer pressure requirements and maybe adjusted later by use of the inbuilt valve. The free of charge ACE calculation service designs the gas springs with mounting points specifically for the particular application. A variety of additional components makes assembly even easier and allows universal application of the gas springs.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Valve Technology Force range max. 100 N Stroke 20 mm Universal and tailor made: ACE industrial gas push type springs of the NEWTONLINE family offer perfect support of muscle power with forces from 10 to 13,000 N with body diameter of 8 to 70 mm. With their high quality features the NEWTONLINE gas springs form the industry standard. These durable and sealed systems are ready for installation, maintenance-free and filled with pressurised nitrogen gas. They are supplied filled according to individual customer pressure requirements and maybe adjusted later by use of the inbuilt valve. The free of charge ACE calculation service designs the gas springs with mounting points specifically for the particular application. A variety of additional components makes assembly even easier and allows universal application of the gas springs.

Request for a quote

JUNIE - JUL. NIEDERDRENK GMBH & CO. KG

Germany

Star Track Push-Open Hinge, protruiding cranking 0 mm, drilling distance 45 mm, without spring, material: steel nickel plated

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• Containing pressing pliers and the most popular insulated end-sleeves • For establishing solderless, electrical connections according to DIN • Handle strip pushed in flush • Sortimo L-BOXX Mini, plastic system case made of shock and impact proof ABS-plastic for more mobility

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®) Working Temperature -40° C ... +106° C / -40° F ... +223° F Valve Design Poppet Valve Connection Push Disconnection Actuate Push Sleeve Connect Under Pressure Male Tip/Female Body Application Construction Machinery, Industrial Hydraulic ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Plating and Thick-Film-Passivation (Chrome III) Standard Seal Material(s) Special compound Working Temperature -35° C ... +130° C / -31° F ... +266° F Valve Design Flat Face Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Rescue and Tensioning Hydraulics ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Plating and Thick-Film-Passivation (Chrome III) Standard Seal Material(s) Special compound Working Temperature -35° C ... +130° C / -31° F ... +266° F Valve Design Flat Face Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Rescue and Tensioning Hydraulics ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®), PTFE Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Flat Face Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Agricultural and Forestry Machinery ISO Interchange ISO 5676

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®) Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Poppet Valve Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Industrial Hydraulic ISO Interchange ISO 7241-1, Series B

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®) Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Poppet Valve Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Agricultural and Forestry Machinery ISO Interchange ISO 7241-1, Series A

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Plating and Thick-Film-Passivation (Chrome III) Standard Seal Material(s) NBR (Buna-N®), PTFE Working Temperature -30° C ... +100° C / -22° F ... +212° F Valve Design Poppet Valve Connection Push Disconnection Pull Connect Under Pressure not allowed Application Agricultural and Forestry Machinery ISO Interchange ISO 7241-1 Series A, Size 12,5

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel, Zinc-Plating and Thick-Film-Passivation (Chrome III) Standard Seal Material(s) NBR (Buna-N®), PTFE Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Poppet Valve Connection Push (When mounting the Sleeve in Bulkhead), Push and actuate Push-Pull Sleeve Disconnection Pull (When mounting the Sleeve in Bulkhead), Actuate Push-Pull Sleeve Connect Under Pressure Male Tip Series HU up to the max. Working Pressure allowed Application Agricultural and Forestry Machinery ISO Interchange ISO 7241-1 A and ISO 5675 (for selected sizes)

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel, Zinc-Plating and Thick-Film-Passivation (Chrome III) Standard Seal Material(s) NBR (Buna-N®), PTFE Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Poppet Valve Connection Push (When mounting the Sleeve in Bulkhead), Push and actuate Push-Pull Sleeve Disconnection Pull (When mounting the Sleeve in Bulkhead), Actuate Push-Pull Sleeve Connect Under Pressure not allowed (Male Tip Series HU up to the max. Working Pressure allowed) Application Agricultural and Forestry Machinery ISO Interchange ISO 7241-1 A and ISO 5675 (for selected sizes)

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®), PTFE, PU Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Flat Face Connection Push Disconnection Actuate Push Sleeve Connect Under Pressure Male Tip Series FU up to the max. Working Pressure allowed Application Construction Machinery, Industrial Hydraulic ISO Interchange ISO 16028

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Brass Surface Finishing - Standard Seal Material(s) FKM (Viton®) Working Temperature -25° C ... +200° C / -13° F ... +392° F Valve Design Poppet Valve Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Industrial Hydraulic ISO Interchange ISO 7241-1, Series B

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®), PTFE, PU Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Flat Face Connection Push Disconnection Actuate Push Sleeve Connect Under Pressure not allowed (Male Tip Series FU up to the max. Working Pressure allowed) Application Construction Machinery, Industrial Hydraulic ISO Interchange ISO 16028

Request for a quoteResults for

Push push - Import exportNumber of results

42 Products