- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- production line

Results for

Production line - Import export

XIMEA GMBH

Germany

We design for performance! When it comes to custom engineering we work with you as a team in close collaboration. That is before, during, and after the job is done. If you aim to develop your project further we are always eager to assist you with a creative, rapid, and highly efficient OEM-design. Starting from scratch or using any existing XIMEA product as a seed, we provide services all the way up to full custom developments and manufacturing.

Request for a quote

BERNSTEIN AG

Germany

Whether on the conveyor belt or on the machine – when maximum safety is required, BERNSTEIN rope pull switches provide a proven and reliable technical solution.The switches can be deployed flexibly, are easy to install and convenient to handle.And most importantly: they offer maximum safety when it is needed. The SR series of safety rope pull switching devices are designed and approved in accordance with the standards IEC 947-5-5, DIN EN 60947-5-5 and ISO 13850. On actuation or in the event of cable breakage, the emergency stop switching device locks automatically and can only be reset to its initial setting by using the resetting device on the switch. • Protection class IP67 • Stable and durable plastic housing (PA 6 GV) • Can be deployed at temperatures between –25 °C and +70 °C • Flexible handling with three M20 x 1.5 cable entries • Easy installation due to the maximum connection space • Up to four positively driven NC contacts

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

The casting lines comprise formulation, preparation, mixing, metering and casting of the parts. Also included is a pre-heating zone for the parts resp. molds prior to the casting devices as well as gelling and curing ovens systems. Fully automatic flow of the parts/workpieces through the entire process, from pre-heating to curing.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

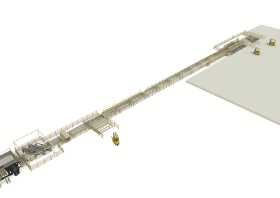

MDF forming lines consist of machines for forming and monitoring the bre mat. Additional devices for quality monitoring complete the function. The plant modules can be adjusted to the respective requirements thus preparing the mat optimally for its compaction in a ContiRoll®. The equipment is designed to produce board thicknesses between 1.5 and 40 mm without any problem. The forming belt conveyor is a modular design as well tuned to plant output and feasible board formats. Features Forming belt with pneumatic tensioning station as well as electric drive station and integrated automatic reject m Integrated belt scale for controlling the mat former output to ensure consistent product quality Mat moisture meter Automatic edge trimming system ex prepress Monitoring equipment to prevent steel belt damage peak detectors metal detector

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The cooling and stacking line, which is downstream of the ContiRoll®, is the rst part of the nishing line. This is where the continuous process becomes a discontinuous one and the boards are cut from the endless mat. The cooling and stacking line is the rst section of an intralogistical concept that Siempelkamp develops with the customer: We work with the plant owner to dene the best master-board formats that will allow the later end-product formats to be made without ocuts. We develop all downstream processes for the master board and product on the basis of optimum material ows in constant dialogue with the customer. To this end, Siempelkamp sets up a team of experts that will act as the reliable partner throughout the process – from the intralogistical concept, technical implementation, assembly and commissioning/start-up to ongoing support Features and functions Saw section Rejects area Cooling section High-stack forming

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Production line - Import exportNumber of results

5 ProductsCompany type