- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- product and process control

Results for

Product and process control - Import export

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Ventapp dampers are used for controlling hot, ue and process gases in various industrial branches often in connection with VENTAPP industrial fans.Process optimisation and consistency, increased energy eciency - VENTAPP oers a wide range of high-quality industrial dampers and air intakecontrollers designed even for the most extreme boundary conditions. Ampleaccessories like monitoring equipment, special switches, add-on sets and closing devices ensure adequate adjustment to the production process. FeaturesSingle or multi-vane control dampers for controlling stable processes Safety dampers with self-triggering counterweights to respond toemergencies and ensure safe maintenanceControl and non-return valves with heatable seal air to prevent overpressure and corrosionAir intake controls for energy ecient blower controlAdvantagesCustomer-specic manufactureRobust designHigh ependability and operational safety Diverse accessoriesMaintenance and repair servicesquare up to 3,000 x 8,000 mm

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

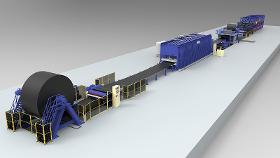

One of Siempelkamp’s core competences is the design and manufacture of presses for the rubber industry. With our expertise in this eld we are the world’s number one in steel-cord and conveyor-belt presses with many of the conveyor belts used around the world being manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straightrunning stability. Siempelkamp's excellent manufacturing and high-quality plants are eld proven. Services Single-source supplier Uniform pre-tensioning of the individual steel cables Best pressure distribution in our vulcanising presses Cable clamping and tensioning device with a heavy clamp Compactor lorry with pre-press Pull-roll stand Reeling elements Advantages Excellent thickness tolerances due to multi-cylinder press without requiring press bolsters Safe vulcanizing process for various belt widths by controllable pressure distribution Transparent and controllable production process

Request for a quote

HAVER NIAGARA GMBH

Germany

The Haver R-Class is a reject screening machine. It has been developed in a compact design and especially for fully automatic screening, upgrading well-known Big Bag and silo systems. The use of HAVER R-CLASS guarantees that no reject or agglomerates will get into the final product at the packing process. The control sieve (round-shaped element) is available for every application, i.e. in different sizes and with small mesh sizes. Based on the very small dimensions of the screening machine, it is possible to expand existing plants without any problems. Even in case of a large feed quantity and small mesh widths a constant material flow is guaranteed. The range is up to 1000 kg/h feed rate. The Challenge Do you have rejects and agglomerates in your final product? Especially in the food and pharmaceutical industry this could lead to significant complications. By using the Haver R-Class it is possible to solve the problem without affecting the performance of the plant. The...

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC milling, can process a variety of materials,like Aluminum, Brass, copper,steel, Beonze, Steel Stainless .... Working length range:X:1-1066mm, Y:1-600mm,Z:1-600mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Product and process control - Import exportNumber of results

4 ProductsCompany type