- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing

Results for

Processing - Import export

BLUESENS GAS SENSOR GMBH

Germany

Monitoring of oxygen concentrations in bioprocesses in real time offers the possibility to learn about the actual metabolic state of the culture and use the information for process optimization. Values like OUR, OTR, RQ or even feeding strategies are essential for process control and optmization. BCP-O2 oxygen analyzers in the simple PA housing have a space saving design and are suitable for small scale stuides (e.g experiments in shake flasks) up to industrial scale processes. Due to the integrated automated temperature and pressure compensation gas cooling, specific valves or pipes are unnecessary. Gas concentrations can be measured directly in the process without expentiture.

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

Conveyor rollers made off — Plastic (with steel balls or stainless steel balls) — Steel, galvanized (with steel balls) Roller diameter: 48 mm For axis diameter: 6 mm, 8 mm

Request for a quote

ACTIVE ANTS

Germany

Returned items are inspected, restored to their original condition and re-stocked. Our returns process meets the strict guidelines of platforms like Zalando and Amazon. If you also sell through these platforms, this is extremely convenient.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts of electric bicycle stand, mainly machine by CNC milling machine, then process natural anodize.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Anodized aluminum is a process that enhances the durability and resistance of aluminum by creating a protective oxide layer on its surface. This layer not only prevents corrosion and wear but also allows for custom surface coloration. Here are some key points about blue anodized aluminum: Color Options: Aluminum can accept a wide spectrum of anodized colors, including blue. Other available colors include pink, black, silver, gold, green, orange, red, and purple.Anodization serves multiple purposes: Corrosion Resistance: The protective oxide layer acts as a barrier against corrosion. Aesthetics: Anodized aluminum looks sleek and reflective due to the uniform oxide layer. Scratch Resistance: The tough anodic finish increases scratch resistance. Other Qualities: Anodization also affects wear resistance, heat dissipation, and adhesion. blue anodized aluminum combines aesthetics with functionality, making it a popular choice for various applications.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories used for the machine,made by aluminum, then doing black anodizing.Exquisite appearance and precision tolerance control.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC milling, can process a variety of materials,like Aluminum, Brass, copper,steel, Beonze, Steel Stainless .... Working length range:X:1-1066mm, Y:1-600mm,Z:1-600mm

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used for industrial camera accessories。

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is the accessoris used for sensor, after machining, and then process black anodize.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

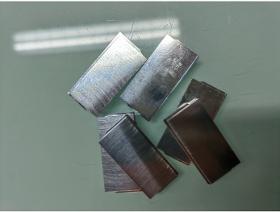

High precision machinery parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used for printer accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accssories use for machines.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

High polish stainless steel flanges are not just functional components in piping systems; they also offer a visually appealing finish that is smooth and reflective. This high polish, often achieved through a process called electropolishing, provides several benefits: Electropolishing Process. Electropolishing is an electrochemical process that removes a thin layer of material from the stainless steel surface, resulting in a smooth and mirror-like finish. This process can also improve the corrosion resistance of the stainless steel by removing surface imperfections where corrosive agents could potentially take hold. Advantages of High Polish Finish Improved Corrosion Resistance: The smoother surface reduces the number of crevices where corrosion could start, thus enhancing the flange’s longevity. Easy Cleaning: High polish surfaces are easier to clean and sanitize, which is particularly beneficial in industries like food processing and pharmaceuticals.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

Our fields of expertise are in areas where processes are influenced by temperature changes. We act as a reliable partner always there where electric heating technology, integrated with functional process control, requires high operational safety.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

Typical Fields of Application are in the chemical, petrochemical, railroad and shipbuilding industries, in the machine and industrial equipment construction. CSN® circulation heaters are manufactured in close coordination with our customers from a few watts to the megawatt range, a division in individual circuits is made according to customer’s requirements. Equipment for installation in hazardous areas we produce in protection class „Ex d“, „Ex de“, „Ex e“. On request, CSN® circulation heaters are supplied with optimized process controls. Please contact us to talk about the most appropriate control system. Schniewindt is certified by the Lloyd’s Register to produce equipment according to the Pressure Vessel Directive 2014/68/EU and a certificate from TÜV (Technical Monitoring Agency) certifies that we meet the prerequisites for welding procedures according to AD 2000 Merkblatt HP 0 / DIN EN 7293.

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

BEKOSPLIT splitting plants clean emulsified condensates which occur as a result of unfavourable initial conditions or of certain lubricant/compressor combinations. In addition to compressed-air condensate, other oil-containing industrial wastewaters can also be processed. Water-insoluble organic substances and a large variety of solid contaminations are removed from the water. Any heavy metals, dirt and paint particles contained in the water are reliably adsorbed

Request for a quote

W. MÜLLER GMBH

Germany

Space-saving in a vertical (e.g. for retrofitting) but also in a horizontal version, our extruders are available in many variations for your specific needs. For applications with larger throughputs, we have high-quality extruders with heat-separated feed zone cooling, which deliver a high-quality melt for the further process. We also offer coordinated screw designs for special materials such as PVC, PA, EVOH, E-PET or adhesive layers.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHNIEWINDT GMBH & CO. KG

Germany

For all CSN® heaters and heating systems we manufacture perfectly matching process controllers. Please contact us to talk about the appropriate control options. CSN® standard contactor controls consist of Enclosure Main switch Load protection Control protection Step protection Indicator light In economical heating systems the load is controlled by thyristors, thus ensuring an accurately dosed power supply. CSN® thyristor controls consist of Enclosure Main switch Semiconductor fuses Contactor Solidstate relays in 3phase economy circuit or Thyristor Control switch Control protection PID controller Indicator light Of course, we also manufacture process controls according to your individual requirements! Further information about our CSN® Controls

Request for a quote

J.D. GECK GMBH

Germany

Our competences ,Flexible and toolbased sheet metal processing ,2D laser cutting, punched and folded parts. ,Bent wire parts madetomeasure ,Manual and automated welding. We would be happy to manufacture your preliminary products. More information available at https//www.geck.de

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Stamped parts / contract manufacture Your products delivered punctually As a flexible stamping business, Schulz Stanztechnik manufactures various stamped and stamped bent parts for the most diverse areas of application from conveyance technology components, the automotive industry to mechanical components such as washers and angle connectors or entire assemblies. We place particular emphasis on high-quality and punctual manufacture and delivery of the ordered products and services. We are also in a position to meet special requests of our customers at short notice. Alongside the actual stamping process, Schulz Stanztechnik carries out numerous additional tasks, such as the creation of threads, use of installation parts or the installation of several components to the stamped parts. These activities can be carried out during stamping as well as in a separate work process.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

In the FIPFG process, a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. Highly elastic, dimensionally accurate and cost-effective seals that are perfectly connected to the workpiece: KOPP has been offering this to you for more than 15 years in the form of FIPFG sealing systems. In the FIPFG process (formed-in-place-foam-gasket), a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. The possibilities of the technology are as diverse as our customers' requirements for the seals themselves. This makes on-site technical advice essential. Thanks to our experience and technical expertise, we always find the perfect solution with our customers. Through our own toolmaking and construction and application consulting, we can produce quickly, flexibly and cost-effectively.

Request for a quote

SCHELLEN & FLACK GMBH

Germany

Applications of structural steel hollow sections include hoists, frame structures, and beams and columns. With structural steel hollow sections, you can significantly reduce the weight of your steel structures and achieve savings in material and manufacturing costs – without limiting freedom in design.

Request for a quote

SCHELLEN & FLACK GMBH

Germany

Stainless steel tubes have become an indispensable part of everyday life. We hold onto them on the bus or use them as railings in houses. In the furniture industry, stainless steel tubes are used as wardrobe rods and as components for furniture. In their largest form, they serve as pipelines for oil and gas.

Request for a quote

SCHELLEN & FLACK GMBH

Germany

Whether chassis applications with high dynamic stress and safety-relevant functions or lightweight solutions for the highest crash requirements. Our claim is to find the technically and economically best solution for your individual requirements

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Most modern equipped, we meet your demands on highest level! For the mechanical processing, we use modern manufacturing technologies which ensure tailor-made optimized solution on a constantly high quality level. Whether individual parts or small and medium-scale productions, whether small components or XXL parts, we remain at your service. For the customer's data transfer, our modern 2D & 3D CAD systems are available. ■ CNC turning: up to 3000 mm / Ø420 mm (118"/Ø16") ■ CNC milling: up to 7000/2500/1500 mm (275"/98"/59"), part weight up to 10 T (2204 lbs) ■ 5-axis treatment up to Ø 1000 mm (39"), part weight up to 1,2 T (2645 lbs)

Request for a quote

BARTSCHER GMBH

Germany

Simply practical – 6 programs to choose from to allow times to be down to the second. An acoustic signal indicates the end of the grilling time.

Request for a quote

GSW SCHWABE AG

Germany

GSW FeederStraighteners, series VRMA are just as simply operated as our Straighteners of the RMA series. With servo drive and length measuring system they offer the additional functionality of material feeding (positioning) over just straightening. Their most common application is cuttolength and spacesaving coil feeding. The already revolutionary alligatorhead can be extended with hydraulic opening for full piloting when feeding into stamping presses with progressive dies. For especially heavygauge materials or high demands in flatness, our VRMZ series FeederStraighteners are the correct answer. They process crosssections as large as 2000 x 5,0 mm. up to 2000 mm material width and 16 mm thickness max crosssection approx.. 2000 x 5 mm or 650 x 10 mm max net output approx. 50 – 150 m/min max cycles with piloting approx.. 40 – 100 SPM

Request for a quote

BARTSCHER GMBH

Germany

Induction cooker with 3 hobs for individual use. Depending on the type of food preparation, 3400 Watt can be distributed over 3 or 2 hobs.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

X2000NC for producing door strikers Modular tool set on an X2000NC line for the production of door strikers from 8 mm wire. Striker sprinter tool, 3 stations, 2 m back wall, feeding of coil material via NC roller infeed, cycle output: approx. 60 pcs/min, ready-to-use, weight approx. 10 t Door striker production With these specifications, our X2000NC is the world’s fastest system for the production of door strikers for the automotive industry. With tool changes, different striker shapes can be achieved, as well as processing details such as upsetting or tapering at wire ends. Our one-of-a-kind production model enables cycle times of more than 60 pcs/minute. For this reason, we’d prefer not to share the technical details of our strategy online. If you’re interested, please arrange a meeting with a member of our field sales team. Incidentally, we also build assembly systems for coupling door strikers to striker plates.

Request for a quoteResults for

Processing - Import exportNumber of results

92 ProductsCompany type

Category

- Plastic material processing (14)

- Food Processing (7)

- Carbon and graphite - electrical components (5)

- Pipes and tubes, cast iron (4)

- Forming - steels and metals (3)

- Milling - machine tools (3)

- Processing and recycling of waste (2)

- Sensors (2)

- Bending - steels and metals (2)

- Bicycle accessories (2)

- Forming, rubber - machinery (2)

- Monitoring and control equipment (2)

- Milling - steels and metals (1)

- Measurement and control instruments (1)

- Steels and metals - machining (1)

- Steels and metals - welding and brazing (1)

- Bending machine tools (1)

- Measurement - Equipment & Instruments (1)

- Metal industrial presses (1)

- Warehouse logistics (1)