- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- process plants

Results for

Process plants - Import export

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Control cabinets form the technical "central nervous system" of every production plant. They supply machine and plant components with electrical energy, protect electrical circuits, control drives and network machines with the Internet. In addition, they act as an interface for all information on the current plant and processing status and link production exactly where processes need to be accelerated and efficiency increased. Our subsidiary ATR Industrie Elektronik GmbH is your competent partner for the construction of switchgear and switch cabinets. We supply a wide range of different versions based on all current national and international standards. Switchgear is used in almost all industries, in addition to the wood-based panel and metal industry, e.g. in the automotive sector, in turbine and compressor technology, in energy supply or also in cooling and air-conditioning technology.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

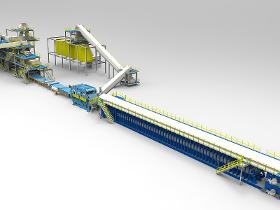

Design and production of press-systems for the rubber industry is one major core competences of Siempelkamp More than 100 years of experience in rubber press lines More than 100 years ago, we put in operation the first conveyor belt press on the market. Only 20 years later, the first large vulcanizing press with a closed frame construction went successfully in operation. Even today, our presses and systems for the rubber industry have unqiue advantages: Durability, speed, high availability and efficiency, which are the most important arguments for our customers to choose a Siempelkamp plant. Proven technology that is trusted in the rubber industry With our broad expertise in the fields of rubber processing industry, we are the world market leader for steel cord and conveyor belt presses. A large part of the conveyor belts used around the world are manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straight-running stability.

Request for a quote

IBK WIESEHAHN GMBH

Germany

Description - Suction and delivery hose for conveying hydrocarbons with an aromatic content up to 50% - Excellent for use on tank trucks, rail tanks and processing plants in the oil industry - Meets the standards EN 12115:2011 - Suitable for transferring gasoline, diesel, biodiesel blends including B100 and fuels based on ethanol Tube - NBR1, black, smooth, antistatic (R < 10^6 Ω), resistant to gasoline, oils, fats, hydrocarbon and gas Reinforcement - Plies of high strength synthetic textile - with or without Embedded steel helix wire - Built-in copper wires are available upon request Cover - NBR, black, smooth, antistatic (R < 10^6 Ω), resistant to abrasion, ozone, weather, gasoline, fatsand minerals oils, cloth finish

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Using a ContiTherm preheater upstream of the ContiRoll® press increases the production output of a wood-processing plant signicantly. It is an additional component integrated into the forming line and serves to preheat the mat before it is transferred to the ContiRoll® infeed to just below the temperature at which the glue starts to cure. A steam-air mix is conveyed through the mat. During this process, the steam condenses at the bres or particles, heating them up. The preheating temperature can be set most accurately by varying the steam content of the mix. The machine is separate into two to four sections (seen in working direction). Depending on the application these sections are designed for a unidirectional or a bidrectional steam injection or equipped with hot platens heated by thermal oil. The width of the steam boxes in an MDF-plant can be extended by additional segments to optimise steam-air conveyance.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

VENTAPP radial fans are used in wood-processing plants where air or loaded air is conveyed under increased pressure. They convey gases, bres, and particles; they are used for wetting, drying or ltering of media. In energy plants, in bre drying, for mat formers and dust extraction systems they form integral parts of Siempelkamp plants. Features Pressures beyond 20,000 Pa Temperatures up to 700 °C Impeller wheel diameters up to 3,150 mm Circumferential speed up to 200 m/s Gas-tight and pressure-resistant design ATEX Advantages High eciency Smooth operation Robust design Low caking, high wear resistance High dependability and operational safety Diverse accessories Maintenance and repair service Variants Drive type Casing positioning Size of all components Angular position Material Colour

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAYFRAN GMBH

Germany

Machine pump back stations are the ideal solution for the transport of swarf and coolant (oil or emulsion). They are easy to retrofit nearly, to all types of machine tools. Crushers must be added at those machines producing long swarf. High pressure systems can be added easily. Swarf and coolant (oil as well as emulsion) will be conveyed through pipes to a central filter or processing plant

Request for a quote

HAVER NIAGARA GMBH

Germany

Complex plant projects with multiple components and planning phases require comprehensive experience and expertise in plant integration. HAVER & BOECKER links our core screening, washing and pelletizing technologies with supplementary components of our vendors. The North American mineral processing brand W.S. Tyler is also a part of HAVER & BOECKER. Tyler technology can be implemented into your plant. HAVER & BOECKER offers the “single source” principle where a single contractor takes over full responsibility for project execution. Engineering knowledge, modern systems integration and software solutions provide the basis for successful planning and implementation. Building a plant with our customers is a mutual partnership. The processing specifications and needs of our customers, in combination with our global experience, are the keys to achieving a profi table mineral processing plant. Screening and Crushing Plants Washing Plants Pelletizing Plants Screening and Crushi

Request for a quoteResults for

Process plants - Import exportNumber of results

8 ProductsCompany type