- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- positioning systems

Results for

Positioning systems - Import export

LENORD, BAUER & CO. GMBH

Germany

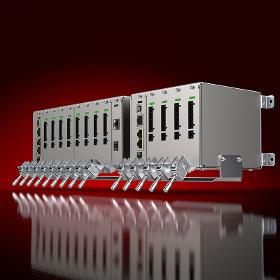

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Intelligent connection box in modular design • Two housing variants with 4/9 slots available • Module combination for control of up to 17 axes • Conveniently configurable via SeGMoSupport Tool

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Fast and controlled format changes thanks to the intuitive SeGMoAssist digital position display from Lenord+Bauer, that's now possible even in plants without fully automated adjustment. • For guided format adjustment • Display of nominal and actual position to facilitate manual adjustment processes • Bright graphical display • Presentation of customerspecific pictograms • Optional for rotatory and linear position measurement • Insensitive to EMC interference • Ready for use immediately after power on due to absolute multiturn position detection • Maintenancefree

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

The fully ULcertified positioning system from Lenord+Bauer consists of three individual elements that can be flexibly combined as required positioning drives by the name of SeGMo, the decentralised SeGMoBox control unit for flexible fieldbus integration and the associated hybrid cable solution, including connectors, that is suitable for use with drag chains. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. Lenord+Bauer also offers these for standalone use. With nominal torques of up to 15 Nm, they cover the capacity range typical for secondary axes. Integrate the drives directly into your control system with the function blocks. Alternatively, you can automate up to 17 secondary axes using the decentral SeGMoBox. The box handles the power management for the connected drives and concentrates the interaction with the system control.

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

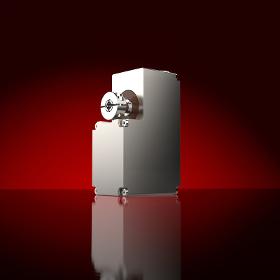

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive with through hollow shaft • Batteryfree multiturn absolute encoder • Aluminium housing • Optionally with cULus component recognition

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Interface for controlling up to 5 positioning drives • Integrated power management • Straightforward commissioning of the SeGMoPositioning • Depending on the design either with cULus component recognition or cULus listing • Support Tool for advanced commissioning and configuration

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Fast and controlled format changes thanks to the intuitive SeGMoAssist compact nominal value display from Lenord+Bauer, that's now possible even in plants without fully automated adjustment. • Display supports the operator, e.g. during format or tool changes • Bright graphical display • Presentation of customerspecific pictograms • Insensitive to EMC interference • Maintenancefree

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Conventional thermometers measure the temperature by means of length or volume change of a material, and are only suitable as display instrument. Temperature sensors from Lenord+Bauer use resistance thermometers that feature an almost temperaturelinear r

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive for installation situations with little space • Monitoring of important system parameters ensures reliable operation (overload protection) • Ready for use immediately after power on due to absolute multiturn position detection • Maintenancefree due to sealedforlife lubrication • Optionally with cULus component recognition

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive suitable for a wide range of applications in various industrial areas • Batteryfree multiturn absolute encoder • High dynamics • Optional use with the SeGMoBox or as a standalone device • Optionally with cULus component recognition

Request for a quote

ROLLON GMBH

Germany

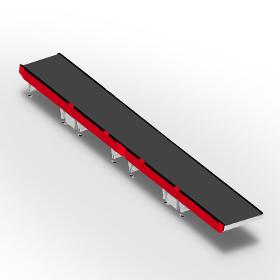

Versatile transfer system for metal sheet handling, designed as the main element in a series of presses which eventually combine with load/unload systems. The system features high positioning precision with heavy duty cycles and high dynamics, and is also available for very extended lengths. It manages cantilever loads to keep one side of the series free for operations. The system is driven by a belt with Ω transmission. The Z axes can be placed at different distances, according to the loads. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

BURRE HYDRAULIK GMBH

Germany

Piston rod with ceramic coating With integrated position measuring system Application: floodgate and bridge lifting technology

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The versatility and and capability of LAWECO products is most notably shown in coil processing systems. In the infeed and outfeed areas, coil lifting carriages primarily handle the coil. In conjunction with various rack systems even complete solutions can be realised. In the stack areas, stationary and movable scissor lift platforms provide the required handling. Here, it is also our goal to respond to the wishes and requirements of our customers and to provide individual solutions. Load bearing capacity up to 150 t Movable or stationary With simple, tandem or double scissor With materials handling technology or special constructions Mechanical coupling facility With powerful switching hydraulics or control valve technology With weighing device With positioning system

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Stainless steel system for cleanroom production with 400 W laser system Positioning the laser head using a 3-axis servo system Stainless steel lifting door with inspection window.

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Stainless steel system for cleanroom production with 400 W laser system Positioning the laser head using a 3-axis servo system Stainless steel lifting door with inspection window

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinder MZR-1008 is designed as a discharge cylinder of direct support systems on mobile devices, such as Cranes have been constructed. The integrated position measuring system enables the exact position of the support cylinder to be detected. This is hydraulically fixed in connection with the piped double check valve. The cylinder connection is via plain bearing bushes. There are connecting bores for pipe fittings according to BSPP ISO1179-2 in the valve block. Hub and piston rod overhang are variably selectable. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the data sheet for...

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The inclinometer measures the inclination in the gravitational field by means of MEMS sensors (Micro-Electro-Mechanical-System) with subsequent digitisation and linearisation via controllers. It has a stable aluminium housing (optionally stainless steel) and is highly-resistant to vibration and shock. Casting measures in the housing lead to the achievement of protection class IP 69K. The NBT has a redundant MEMS sensor system, which is used to make a plausibility check inside the inclinometer. Only one position datum is output; the plausibility of this is checked using the second system's position datum. Is the deviation of the two systems higher than a certain value, the sensor will enter the failsafe state.

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V6LS from the FD series impresses with its slim design and an expanded degree of freedom, which enables a constant torch orientation when immersing in tight work spaces. Compared to the V6S, the V6LS has an extended arm, which is why the range is increased again. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2006 mm Max. payload: 6kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6000 W Weight: 316 kg

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OTC DAIHEN EUROPE GMBH

Germany

With repetition accuracy of up to ± 0.07 mm, the new high accuracy robot can succeed in even the most demanding of tasks. The deviation from circular diameters of ≤ 10 mm is max. 0.09 mm - half as much as with commercial robots. • Position Accuracy: Highest precision regardless of robot position. • Precision machining: The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The main technical specifications at a glance: Number of axes: 6 Working Range (P-Point): R 1664 mm Max. payload capacity: 20 kg Positional repeatability: +/- 0,08mm Drive System: AC Servo Motor Drive Power: 7900 W Weight: 355 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4S from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1435 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 3550 W Weight: 189 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot V20S from the FD series is the optimal robot for medium-heavy loads. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P point): R 1710 mm Max. payload: 20kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 6600 W. Weight: 321 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V210 is extremely efficient when handling heavy weights (up to 210kg). Like all robots in the FD series, the FD-V210 also has collision protection through improved fault detection / elimination. Thanks to the easily accessible cable routing, the V210 is very easy to maintain. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. The most important technical data at a glance: Number of axes: 6 Max. payload capacity: 210 kg Working Range (P point): R 2674 mm Positional repeatability: +/- 0.15 mm Drive system: AC servo motor Drive power: 18000 W

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V50 has the highest efficiency when handling medium loads (up to 50 kg). Like all robots in the FD series, the FD-V50 also has collision protection through improved fault detection / elimination. Comparatively minimal footprint with a maximum working area. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. On request also with the improved protection class IP67. The most important technical data at a glance: Number of axes: 6 Max. payload capacity: 50 kg Working Range (P-point): R 2050 mm Positional repeatability: +/- 0.07 mm Drive system: AC servo motor Drive power: 14750 W Weight: 640 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-H5 (H) is a compact, high-speed handling robot for small loads. A larger free space in the area of the joint creates a large arm space. Like all robots in the FD series, the H5 model also has collision protection through improved fault detection / elimination. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. The most important technical data: Number of axes: 6 Working range (P-Point): R 866 mm Max. payload capacity: 5 kg Positional repeatability: +/- 0.05 mm Drive System: AC Servo Motor Drive Power: 1440 W

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The FD-V166 is extremely efficient when handling heavy weights (up to 166kg). Like all robots in the FD series, the FD-V166 also has collision protection through improved fault detection / elimination. Thanks to the easily accessible cable routing, the V166 is very easy to maintain. In addition, the integrated hose package guarantees optimal protection against getting caught during the robot operation. The most important technical data at a glance: Number of axes: 6 Max. payload capacity: 166 kg Working Range (P point): R 2654 mm Positional repeatability: +/- 0.1 mm Drive system: AC servo motor Drive power: 18000 W

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With a capacity of up to 2500 pieces of baggage per hour, strength and resilience are fundamental. The Motion06 Vertical Sorting Unit Belt Conveyor is used for the distribution and merging of baggage and general cargo between two or three levels. The belt conveyor incorporated into the Vertical Sorting Unit is height adjusting using a top of the line lifting system with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. It is also possible to use it in flight baggage systems with a container system. The belt conveyor is replaced by an appropriate conveyor element for this purpose. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Motion06 Manual Sorting Belt Conveyor is used in those places where bulky luggage is collected centrally from the various luggage lines and prepared for inspection. As a special solution, it can be adjusted to a huge range of conditions, such as conveyor height, positioning of the control system, belt lengths, conveying direction or conveying speed. The heart of the sorting belt is formed by two plastic link conveyors, which are characterised by a very smooth and wearresistant surface and have a far longer life span than roller tables that have been used in the past. The individual pieces of luggage are transported to a certain position by the electronic link conveyor and then manually pushed off in the direction of the conveyor. This procedure makes the work of airport personnel considerably easier.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Compact, flexible, fixmounted or extendible, and perfectly maintainable. The Motion06 CheckIn, with the CheckIn Premium, is the highest standard of design and functionality. The CheckIn Easy, based loosely on the motto, “less is more”, completes the CheckIn department at the airport base. The whole family of CheckIn is characterised by optimal operability by the operator and optimal accessibility for the passenger. The CheckIn is the passenger’s point of contact with the entire flight baggage system. Whether it be the fixmounted or the extendible version, simple and fast accessibility for maintenance and cleaning work is guaranteed with both. Depending on the feed rate, you can choose from onebelt, twobelt and threebelt systems. The position of the weighing machine also depends on the customer‘s requirements.

Request for a quoteResults for

Positioning systems - Import exportNumber of results

28 ProductsCompany type

Category

- Driveshafts and micro-motors - electric (9)

- Welding robots (4)

- Automation - systems and equipment (3)

- Conveyor systems (3)

- Laser - cutting and welding machines (2)

- Industrial robots (2)

- Measurement - Equipment & Instruments (1)

- Internal transport systems (1)

- Water purification - systems and equipment (1)