- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- position controller

Results for

Position controller - Import export

IGUS® GMBH

Germany

dryve motor control - Connect, select, control... Precise positioning, endless movements, continuous end-to-end movements - simply defined with the new control for drylin® E linear systems from igus®. - No software or app installation necessary - Quick commissioning - Compatible with numerous industrial controls (e.g. Siemens S7 / Beckhoff) - For stepper motors - Cost-effective

Request for a quote

IGUS® GMBH

Germany

dryve motor control - Connect, select, control... Precise positioning, endless movements, continuous end-to-end movements - simply defined with the new control for drylin® E linear systems from igus®. - No software or app installation necessary - Quick commissioning - Compatible with numerous industrial controls (e.g. Siemens S7 / Beckhoff) - For stepper motors - Cost-effective

Request for a quote

IGUS® GMBH

Germany

dryve motor control system - select, click, control... Travel distances, positions, speeds, operating times - easily defined with the new igus® web-based control system for drylin® E linear systems. - No software or app installation necessary, fast commissioning - Control possible via smartphone (browser), tablet or laptop - Simple and intuitive user interface, control system set up in just a few minutes - Compatible with numerous industrial controllers (e.g. Siemens S7/Beckhoff) - For DC, EC and stepper motors - Cost-effective

Request for a quote

GSW SCHWABE AG

Germany

shock dampening for low operating noise levels absolutely sturdy and warpresistant body design with heavy doublepost guides to smoothly cut even toughest materials with adjustable blade clearance for a most precise cut at any thickness very precise blades made of special steel high operating safety through material guide at entrance and protective cover springactuated hold down clamp (from 250 mm stock width) top/bottom dead center control to monitor blade position counter control mounting bracket hydraulic power units in different sizes electrical control

Request for a quote

GSW SCHWABE AG

Germany

Shock dampening for low operating noise levels Sturdy, warpresistant design with heavy doublepost guides With adjustable blade clearance for a most precise cut at any thickness Very precise blades made of special steel High operating safety through material guide at entrance and protective cover Springactuated hold down clamp (from 250 mm stock width) Top/bottom dead center control to monitor blade position Counter control Mounting bracket

Request for a quote

GSW SCHWABE AG

Germany

Shock dampening for low operating noise levels Sturdy, warpresistant design with heavy doublepost guides With adjustable blade clearance for a most precise cut at any thickness Very precise blades made of special steel High operating safety through material guide at entrance and protective cover Springactuated hold down clamp (from 250 mm stock width) Top/bottom dead center control to monitor blade position Counter control Mounting bracket

Request for a quote

GSW SCHWABE AG

Germany

With 2,5 degree cutting angle for clean, burrfree edges With adjustable blade clearance for a most precise cut at any thickness Very precise blades made of special steel High operating safety through material guide at entrance and protective cover Springactuated hold down clamp (from 250 mm stock width) Top/bottom dead center control to monitor blade position Counter control

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

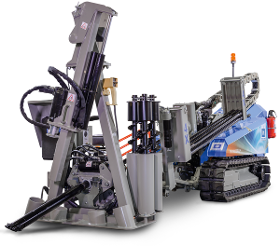

Kubota diesel engine with 28 kW driving power Control station with easy to survey control panel Multifunctional joystick Hydraulic anchor bore unit swivels in three positions Remote control Drill rod magazine with 32 drill rods for 48 m bores Stabiliser blade, rubberised steel track undercarriage

Request for a quote

GSW SCHWABE AG

Germany

shock dampening for low operating noise levels thanks to a heavy overall frame and the sturdy, warpresistant design with heavy doublepost guides even toughest materials can be cut smoothly with adjustable blade clearance for a most precise cut at any thickness very precise blades made of special steel high operating safety through material guide at entrance and protective cover springactuated hold down clamp (from 250 mm stock width) top/bottom dead center control to monitor blade position counter control mounting bracket hydraulic power units in different sizes electrical control

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

REVOLVING CROSS CUT SAW WITH NC PROGRAMMING SYSTEM GAMA 65 K3 Fully automatic circular saw for positioning and controlling via touchscreen with length measuring system EXENSO COMFORT (Pusher system) Application Length stop system (pusher operation), revolving table and sawblade inclination via servo - motor for positioning ( cross cut, mitre cut or compound mitre cut) of heavy workpieces, i.e. carpenter industry, gluelam industry, log house industry, wooden frame work, solid wood, etc. Technical Equipment : - Motor rating 8,1 kW / 400 Vac-50Hz, star / delta start, direct driven - Motor speed 3.000 rpm - Electrical sawblade inclination 90-30° via servo motor - Laser light for cross cutting - Sawblade height at 90° / 245 mm – 45° / 164 mm – 30° / 113 mm - TCT – sawblade 650 x 30 x T 54 - Dust extraction spigot 125 / 80 mm - Revolving table 20° - 160° - Horizontal material clamping system, right - left - pneumatische Kappvorrichtung über ZweihandSteuerung/vollautomatisch

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

LATERALLY MOVABLE UNDERTABLE CROSS-CUT SAW / RIP CUT SAW FULLY AUTOMATIC CIRCULAR SAW FOR POSITIONING AND CONTROLLING VIA TOUCHSCREEN WITH LENGTH MEASURING SYSTEM EXENSO COMFORT (PUSHER SYSTEM) Application : Length stop system (pusher operation), revolving table with lateral movement and sawblade inclination via servo - motor for positioning (rip cut, cross cut, mitre cut or compound mitre cut) of heavy workpieces, i.e. carpenter industry, gluelam industry, log house industry, wooden frame work, solid wood, etc. Equipment / scope of supply : - Motor rating 12 kW / 400 Vac-50Hz, star / delta start, direct driven - Motor speed 3.000 rpm - lateral movement of machine table 400 mm with pneumatic brake system - Electrical sawblade inclination 90-30° via servo motor - Laser light for cross cutting - Cutting height at 90° / 245 mm – 45° / 164 mm – 30° / 113 mm - TCT - sawblade 650 x 30 x T 54

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The STAUFF Press Assembly Machine SPR-PRC-POC allows the pressure/position-controlled pre-assembly and final assembly of cutting rings from the Extra-Light Series (LL), the Light Series (L) and the Heavy Series (S) according to ISO 8434-1 / DIN 2353 on tube ends with outer diameters between 4 mm and 42 mm. The machine is designed as a robust table-top device for continuous operation in the workshop. It is used in connection with hardened and wear-resistant assembly studs FI-FMK and support plates FI-GP which are specially designed for the machine-assisted assembly. The combined pressure/position-control of the device allows wear on the assembly tools to be detected in time before it can have a negative influence on the assembly result. Maximum service life of the tools is achieved through careful handling of the components and practical operation of the assembly machine. Other factors are proper storage (protected against contamination and corrosion), regular cleaning and...

Request for a quote

TOK EUROPE GMBH

Germany

SR2 provides controlled motion to adjust the height at any position. Through its inverse interrupting mechanism, this breakthrough technique conducts driving from the input shaft to the output shaft and locks the input in place even if the drive is stopped. Thanks to this new mechanism, you can easily lift heavy objects and lock them precisely into position. This new control motion is perfect for applications such as adjustable tables, handicap sinks, and more. [Benefits] ・ No power supply ・ Easy operation ・ Ready to install ・ Competitive price

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Excellent board qualities are only achieved when the endless particle mat is degassed and compacted before being transferred to the ContiRoll®. This is realised by the Siempelkamp prepress for particleboard production. Features, function An air evacuation zone, the angles and levels of which are adjustable. High-pressure zone incl. hydraulic position control Two circulating belts Belt cleaning systems incl. extraction system installed along all the belts Advantages Eective prevention of soiling or material jams No belt indents in the board surfaces Variants, options Endless air evacuation belt

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

A homogeneous compaction of the formed mat is indispensable because this is the only way to realise high production speeds and smooth mat transfer to the ContiRoll®. Adequate compaction is provided by the prepress suitable for the production of MDF from 1 to 42 mm. Features, function Two air evacuation zones, the angles and levels of which are adjustable 1.1. zone 1 with a long degassing section incl. a dust extraction system (optional) 1.2. zone 2, medium-pressure zone and degassing via pressure rollers High-pressure zone incl. pressure rollers and hydraulic position control Three circulating belts 1.1. upper air evacuation belt for the degassing zone incl. motorised belt tracking 1.2. perforated press belt (top strand) for the medium- and high pressure zones 1.3. press belt (lower strand) to relieve the circulating forming belt Belt cleaning systems incl

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The core-layer mat former (pocket orienter) deals with the material ow from the metering bin infeed, the bin discharge front up to the orienter underneath. We use the FinFormer, which orients the strands crosswise to production direction. Distribution rollers form parts of the FinFormer, orienting the core-layer strands homogeneously in longitudinal and crosswise directions onto the forming belt underneath. The FinFormer is suitable for all strand geometries. Depending on the requirements one or two mat formers are used. Features Position-controlled, swivelling twin screw conveyor Bin metering belt, incl. weight-per-unit-area control Discharge front rollers, extremely wear-resistant FinFormer including distributing rollers and pocket orienter rollers underneath Level and angle adjustment of the orienter head Advantages Most homogeneous density distribution inside the bin crosswise to production direction Careful strand treatment

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The surface-layer mat former (disc orienter) deals with the material ow from the metering bin infeed, the bin discharge front up to the orienter underneath. We usually employ a disc orienter to create surface layers as it enables high orienting degrees. These, in turn, are important to meet the relevant standard requirements for MOR and MOE in the boards’ main axes. Features Position-controlled, swivelling twin screw conveyor Bin metering belt, incl. weight-per-unit-area control Discharge front rollers, extremely wear-resistant DiscFormer incl. disc rollers Level and angle adjustment of the orienter head Advantages Most homogeneous density distribution inside the bin Orienter head adjustment enabling low dropping levels and perfect orienting of the strands in production direction Positioning of extremely large strands on the outer faces Careful strand treatment Simple, self-cleaning system

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

A press for all processes Beside the pressing systems for industrial production, Siempelkamp manufactures laboratory press systems – both “try-out” presses for laboratoryscale tests with a starting pressing force of 150 t as well as presses for “fullscale testing”. The laboratory press systems are designed for maximum exibility. With it, all processes of composite production can be investigated. For example, it can be investigated whether press technology is an economic alternative for “autoclave” processes. All processes SMC with glass ber or carbon ber RTM PCM Organo-sheet consolidation Thermoplast forming Hybrid forming Integrated molding and joining of hybrid materials All control methods Force control with position monitoring Position control with force monitoring Each process step can be individually dened and programmed: All relevant process data are recorded and displayed.

Request for a quote

FRIWO GERÄTEBAU GMBH

Germany

•Supply voltage: 14V - 65V •Phase current: 300A •Motor types: PMSM •Control algorithm: Field oriented control with flux weakening •Functions: Automatic teach-in, four ride modes, reverse gear, boost, display control, smartphone app •Position feedback: Hall sensor •Analog inputs: 2 •Digital inputs: 2 •Communication: CAN, Smartphone Connectivity •Diagnostic interface: USB, CAN •Diameter: 155mm •Height: 45 mm •Weight: 970 g

Request for a quote

MINEON HANDEL GMBH

Germany

Zinc Alloy Hinge,Size:38*40mm and 57.1*50.8mm available,with different standard Torque 1.4/1.8/2.3/3.4N.m.Technical requirements:After 20,000 times lifespan,the torque attenuation deviation is ± 20%

Request for a quote

MINEON HANDEL GMBH

Germany

Black POM Hinge,Size:43*36mm and 63.5*57.5mm available,Torque strength canbe adjusted by screwdriver.Easy Installation,ROHS compliance.

Request for a quote

MINEON HANDEL GMBH

Germany

Aluminum Alloy Hinge, POM shaft,Size:65*55mm,Torque strength canbe adjusted by screwdriver,Easy Installation,ROHS compliance.

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

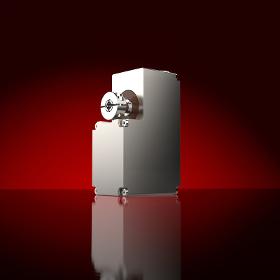

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive with through hollow shaft • Batteryfree multiturn absolute encoder • Aluminium housing • Optionally with cULus component recognition

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive suitable for a wide range of applications in various industrial areas • Batteryfree multiturn absolute encoder • High dynamics • Optional use with the SeGMoBox or as a standalone device • Optionally with cULus component recognition

Request for a quote

LENORD, BAUER & CO. GMBH

Germany

Automate your feed axes using the SeGMo positioning system from Lenord+Bauer! A simple integration into your plant control system enables you to boost system efficiency in format changes and save time and money. The SeGMo drives are complete mechatronic systems with a batteryless multiturn absolute rotary encoder, gear and motor as well as integrated power and control electronics. • Positioning drive for installation situations with little space • Monitoring of important system parameters ensures reliable operation (overload protection) • Ready for use immediately after power on due to absolute multiturn position detection • Maintenancefree due to sealedforlife lubrication • Optionally with cULus component recognition

Request for a quote

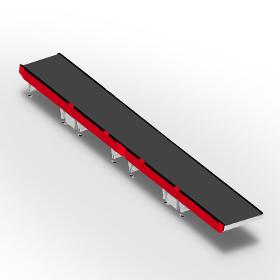

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Motion06 Manual Sorting Belt Conveyor is used in those places where bulky luggage is collected centrally from the various luggage lines and prepared for inspection. As a special solution, it can be adjusted to a huge range of conditions, such as conveyor height, positioning of the control system, belt lengths, conveying direction or conveying speed. The heart of the sorting belt is formed by two plastic link conveyors, which are characterised by a very smooth and wearresistant surface and have a far longer life span than roller tables that have been used in the past. The individual pieces of luggage are transported to a certain position by the electronic link conveyor and then manually pushed off in the direction of the conveyor. This procedure makes the work of airport personnel considerably easier.

Request for a quoteResults for

Position controller - Import exportNumber of results

27 ProductsCompany type

Category

- Metal straightening machines (5)

- Wood veneer - machinery and equipment (5)

- Driveshafts and micro-motors - electric (3)

- Hinges (3)

- Robotics (3)

- Sawing machine tools (1)

- Conveyor systems (1)

- Electrical & Electronic Components (1)

- Mechanical clutches (1)

- Metal industrial presses (1)

- Woodworking - machinery and equipment (1)