- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- or bearings

Results for

Or bearings - Import export

ROLLON GMBH

Germany

1, 2 and 3 Cartesian axis linear modules with rack and pinion drive guarantee precise manipulation of loads from 10 up to 2000 kg with fast and silent functioning. Our main application fields are: robotics, palletization, production line, logistics and manufacturing machines with Cartesian axis movements. Our products stand out for their: easy and quick assembly; high quality and competitive performances; reduced and simplified maintenance; wide range of integrated solutions; possibility of customised solutions; constant technical support and CAD drawings available. Strong points include: hardened sloping tooth racks (ground on request); payloads from 10 to 2000 Kg; up to 12-m beams (longer lengths can be obtained with jointed versions), high level torsional rigidity, precise shape; precise machining of all profiles (on request: repeatability up to +/-0.05mm); hardened and ground steel guide rails, for rollers and ball slides with cage; easy installation of pre-assembled systems...

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

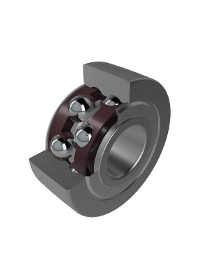

Material Schulz Stanztechnik manufacturers these axial ball bearings using the materials suited to the specific application. For the housing, steel, brass or stainless steel are used; for rings, steel or stainless steel which is always hardened. The balls are made of chrome or stainless steel, which is also always hardened. All material combinations – depending on their conditions of use – are possible for the assembly of the individual parts. Various surface coats for the individual parts can be supplied as well as finished bearings: brass which is uncoated or nickel plated; steel and stainless steel which is uncoated, zinc plated or nickel plated. All bearings are available lubricated or unlubricated. Structure DLG100 axial ball bearings consist of sheet metal housing, two hardened rings as well as hardened precision balls. Due to their structure, we refer to them as an encapsulated, full ball design.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our KIS track rollers are available as self-retaining, single or double row ball bearings with particularly strong outer rings. In addition to high radial forces, they also absorb axial forces in both directions. Track rollers are characterised by their robust construction featuring particularly thick-walled outer rings with a crowned outer surface (alternatively with a cylindrical outer surface or outer profile). They are designed to carry high radial loads and also tolerate axial loads that can arise due to minor misalignments, skewing or short-term start-up shocks. The assembly is constructed with a fixed inner ring mounted on axles. In this case, the track rollers are not installed in a housing bore, but are supported on a flat raceway (mating track). To ensure a reliable seal, the track rollers are fitted with a lip seal or cover discs on both sides. This prevents the ingress of dirt, dust and other contaminants while maintaining lubrication inside the bearing.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our all-ceramic bearings are characterised by their high corrosion resistance to seawater and various chemicals. They are therefore used, for example, in the chemical industry, in the food and beverage industry, in shipping and in chlorine systems. We can manufacture our full ceramic ball bearings with rings and balls made of zirconium oxide (ZrO2) or silicon nitride (Si3N4), depending on the application. They are available with full balls or with cages made of PEEK or PTFE. The runout accuracies common with precision steel bearings cannot be achieved with all-ceramic bearings, so speed values have to be reduced. Ceramic materials are harder than steel, but also more brittle. Silicon nitride in particular has a low elongation at break and tends to break under tensile stress without prior plastic deformation. We take this into account when selecting the optimum bearing solution for your specific requirements.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

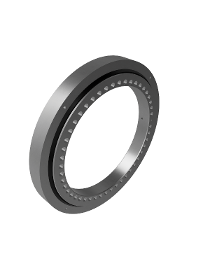

Designed to efficiently support axial and radial forces and tilting moment loads, crossed roller bearings are suitable for applications subject to high loads and speeds. Due to the special crosswise arrangement of the cylindrical rollers in crossed roller bearings, designs with two bearing positions can often be reduced to one. Due to their high rigidity and running accuracy, they offer enormous precision and are used, for example, in robotics, medical technology and lathes. Depending on the application requirements, we at KIS manufacture cross rollers in different configurations. We are happy to advise you on the optimum solution for your application.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our KIS hybrid bearings combine the best of two worlds - the robustness of classic rolling bearings (or stainless steel bearings) and the efficiency of state-of-the-art materials. With an optimised combination of high-quality steel rings and precise ceramic balls, our hybrid bearings offer outstanding strength and durability. Rolling elements made of ceramic offer a current-insulating property. These hybrid bearings have the same dimensions as comparable all-steel bearings and can significantly improve the reliability and robustness of machinery and equipment. In particular, they show their advantages in applications where the bearings are confronted with contamination from abrasive particles, insufficient lubrication, vibrations or current passage. At KIS, we optimise our materials for hybrid bearings to ensure flawless performance in applications under critical conditions at all times.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our KIS slewing rings offer precise rotation technology to reliably connect two or more parts in your application. They are available in a wide variety of designs. As high load-bearing machine elements, they can safely absorb radial, axial and tilting moment loads with one bearing point and thus significantly reduce the effort required for the design of the adjacent construction. Sealed and lubricated, our slewing rings offer long-term performance even under demanding operating conditions. They are used in the fields of mechanical engineering, automation and robotics, among others. We are happy to work with you to develop the right slewing ring for your specific application requirements.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

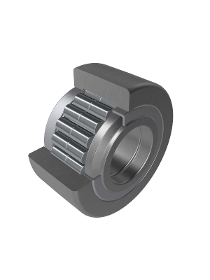

Similar in design to yoke type track rollers with axial guidance, our KIS cam rollers are based on needle roller or cylindrical roller bearings. Instead of an inner ring, they are equipped with a solid bolt. This serves as an inner ring replacement and is provided with a fastening thread. They are ideal for applications that require high rigidity, load carrying capacity and guiding accuracy. Our stud type track rollers are used, for example, in conveyor technology, machine tools and medical technology. Depending on the application requirements, the KIS range offers a wide variety of designs. We are happy to advise you on the right solution for your application!

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our yoke type track rollers are available as single or double row needle roller or cylindrical roller bearings. Depending on the application requirements, the KIS range offers different ready-to-fit variants. Equipped with particularly thick-walled outer rings, our yoke type track rollers can support high radial loads and tolerate axial loads from minor misalignments, skewed running or short-term start-up shocks. Yoke type track rollers are mounted on axles and supported on a flat raceway (mating track). To meet specific requirements, we offer a wide range of different variants. Together with you, we develop the customised KIS solution carefully considering the use of cages, rib rings, seals and the profile of the outer ring running surface.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our self-aligning ball bearings are characterised by their high load capacity and long service life. The KIS range includes both open and sealed self-aligning ball bearings, depending on the requirement. They are particularly suitable for applications with high demands on load performance and wear protection and are used, for example, in industrial machinery, wind turbines and conveyor technology. With low maintenance requirements, they offer long-lasting wear protection. Two rows of balls, two deep raceways in the inner ring and a hollow ball raceway in the outer ring combined for both rows characterise the design of self-aligning ball bearings. Due to the spherical raceway in the outer ring, self-aligning ball bearings are insensitive to misalignments of the shaft to the housing, compensating for static and dynamic angular errors within certain angular limits in a rotating shaft system. We are happy to develop the ideal KIS solution for your application requirements!

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

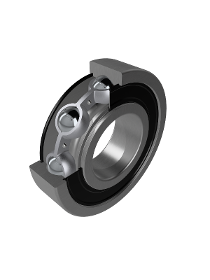

KIS deep groove ball bearings are characterised by their high load carrying capacity and speed stability. Depending on the requirements of your application, they are available in different variants and in both radial and axial design. Our single row deep groove ball bearings are available in open and sealed designs. Open bearings are maintenance-free, while sealed bearings offer better corrosion protection. Single row deep groove ball bearings can support both radial and axial forces. Our double row deep groove ball bearings feature a higher radial load carrying capacity. They are used when the radial load carrying capacity of single row deep groove ball bearings is not sufficient. Axial deep groove ball bearings are suitable for supporting particularly high axial loads. They are available in both single and double direction. Single direction thrust ball bearings can only support axial forces, while double direction thrust ball bearings can support both radial and axial forces.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

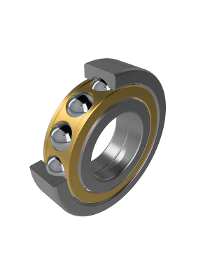

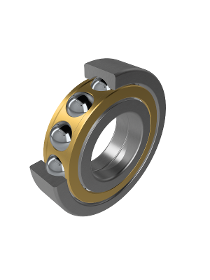

We design our angular contact ball bearings especially for bearing arrangements that have to support combined loads such as radial and axial forces acting simultaneously. As the name suggests, in angular contact ball bearings the forces are transmitted from one raceway to the other at a specific contact angle, oblique to the radial plane. As the nominal pressure angle increases, so does the axial load carrying capacity. Our KIS range includes single-row angular contact ball bearings as well as bearings arranged in pairs. Depending on the application requirement, which for example has a small installation space and requires a rigid bearing arrangement, a double-row design may also be suitable. We are happy to work with you to find the perfect KIS solution for your application.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Are you operating an application requiring a bearing arrangement with high load carrying capacity with low-noise operation? Our durable four-point bearings are the perfect solution for this scenario and can support high axial loads as well as radial forces (relatively lower) in both directions. Four-point bearings are similar in structure to double-row angular contact ball bearings, but are much narrower in the axial direction due to a single raceway. The circular arc-shaped raceways in the inner and outer ring have opposite centres of curvature so that the balls contact the races at four points under radial load. If there is a predominantly radial load, four-point bearings should be avoided due to the higher friction in four-point contact. In assembly, one of the two races, often the inner race, is split to insert the balls. Since four-point contact bearings are often installed radially exposed, the outer rings can optionally be equipped with retaining grooves to prevent rotation.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

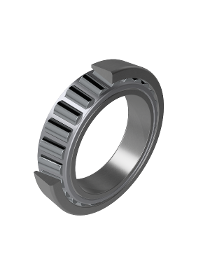

We manufacture our KIS tapered roller bearings in both single and double row designs. Since they can support both axial and radial forces, they can also withstand high loads. Due to their high precision they are suitable for shafts that are to be guided axially precisely (locating bearings) or if the bearing Tapered roller bearings are easy to adjust and disassemble, making them easy to mount and maintain. Tapered roller bearings are the perfect choice for applications where high loads or high precision are required. Our KIS tapered roller bearings are used in a wide range of applications, such as motors, compressors, construction machinery, machine tools and gearboxes. We will be happy to advise you on possible variants with different properties.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

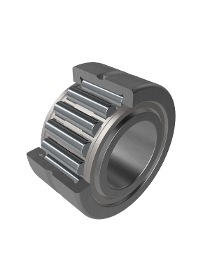

KIS needle roller bearings are ideal for applications that require space-saving rolling bearings with high load carrying capacity. We offer needle roller bearings in both radial and axial designs as well as in combined designs. In bearing technology, cylindrical rolling elements are referred to as needles if the rolling element diameter is ≦ 6 mm and the ratio of rolling element diameter to rolling element length gives a value Dw/lw < 1:3. Radial needle roller bearings are intended exclusively for use as non-locating bearings. The given axial displacement path for bearings with an inner ring allows axial movements between the shaft and the housing. If necessary, wider inner rings are available to allow larger axial displacement paths. Our combined needle bearings are characterised by particularly high precision and efficiency. By integrating both bearings into one unit, combined needle roller bearings are often easier to press in and easier to handle than individual solutions.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

With decades of experience, we manufacture spherical roller bearings at KIS that can support large radial and axial forces in both directions. The perfect solution for applications that have to withstand massive loads. Due to the design of two rows of pendulum-shaped rollers in a common, hollow-ball raceway in the outer ring, our spherical roller bearings can support large radial and also axial forces. This makes them perfect for applications that have to withstand high loads and shocks and compensate for shaft bending or misalignment. In addition to conventional spherical roller bearings (which have no seal and have either a tapered or cylindrical bore), there are also application-specific variants developed for special requirements (e.g. sealed spherical roller bearings or bearings with optimised load ratings). Spherical roller bearings offer high performance and efficiency and are available in a wide range of sizes and designs.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

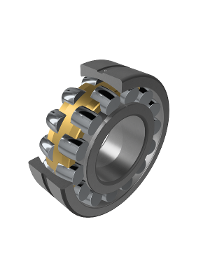

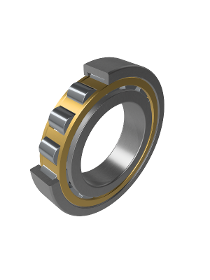

We offer our KIS cylindrical roller bearings in various designs and sizes. In addition to the number of roller rows and the design of the cage, the flanges on the inner and outer rings are also considered. Due to their low friction and high rigidity, our cylindrical roller bearings are the perfect, durable solution for applications with high radial loads. They can also compensate for axial displacements (e.g. due to thermal expansion) and are available in sealed designs. Sealed cylindrical roller bearings are protected from dirt, water and dust. The seal prevents the ingress of contaminants and keeps the lubricant in the bearing. Together with you, we will be happy to develop a customised KIS solution for your requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TOK EUROPE GMBH

Germany

Using the D-series as a foundation, the K-series was developed as a more precision focused version of the D-series. The K-series offers closer tolerances and better accuracy. The outer races can be custom designed for your application. The assembly can include timing pulleys, sprockets, and gears that may be required in sophisticated appliances such as copy machines, printers, and vending machines.

Request for a quote

TOK EUROPE GMBH

Germany

Special bearings for ・ Chemical resistance ・ Heat resistance ・ Corrosion resistance ・ Anti-static

Request for a quote

TOK EUROPE GMBH

Germany

Load capacity of up to 80 kg possible Allowable rotation speed 300+ rpm

Request for a quote

TOK EUROPE GMBH

Germany

Load capacity of up to 80 kg possible

Request for a quote

TOK EUROPE GMBH

Germany

Load capacity of up to 60 kg possible

Request for a quote

TOK EUROPE GMBH

Germany

Plastic ball bearing featuring a polyacetal (POM) outer race, and steel inner race. Its main applications are: office furniture, furniture, vending machines, and refrigerators. There are 3 different types of D-Series Bearings, each serving a different use of application: Hole, Screw, and Riveting bearings. In addition, there are 6 different types of outer housing shapes, which can be seen below. Dimensions range from φ9 to φ48, and load capacity ranges from 2kgf (4.40 lb) to 20kgf (44.0lb).

Request for a quoteResults for

Or bearings - Import exportNumber of results

24 ProductsCompany type