- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- nickel ores

Results for

Nickel ores - Import export

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting*for rods up to 16 mm Ø*nickel plated brass screws*location hole 10 mm Ø

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting*for rods up to 16 mm Ø*nickel plated brass screws*location hole 10 mm Ø

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting*for rods up to 16 mm Ø*nickel plated brass screws

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting*cork lined jaws*capacity 0 – 80 mm*rod Ø 10 mm

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Material Schulz Stanztechnik manufacturers these axial ball bearings using the materials suited to the specific application. For the housing, steel, brass or stainless steel are used; for rings, steel or stainless steel which is always hardened. The balls are made of chrome or stainless steel, which is also always hardened. All material combinations – depending on their conditions of use – are possible for the assembly of the individual parts. Various surface coats for the individual parts can be supplied as well as finished bearings: brass which is uncoated or nickel plated; steel and stainless steel which is uncoated, zinc plated or nickel plated. All bearings are available lubricated or unlubricated. Structure DLG100 axial ball bearings consist of sheet metal housing, two hardened rings as well as hardened precision balls. Due to their structure, we refer to them as an encapsulated, full ball design.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIEDR. FREEK GMBH

Germany

Square cartridge heaters are used where much power has to be installed near the surface of a tool, e.g. in cutting knives, sealing stations or hot plates. With a soft, malleable condition in stainless steel or nickel sheath square cartridge heaters can easily be pressed into common milled rectangular grooves. Apart from the advantageous heat transfer over ¾ of the sheath, it is not necessary to cement or cast in the heater which is imperative for round cartridge heaters. Unlike tubular heaters which are also available in square sections (see chapter Flexible Heating Pipes), the square cartridge heaters have the termination on one side and can be loaded with 16W/cm² (2.5W/in²) due to their special inside construction.

Request for a quote

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

CONEC has developed an ODVA compatible IP67 Fiber Optic connection for harsh indoor and outdoor environment. The new system is a bayonet locking enclosure with integrated LC Duplex Connectors and Adapters. The bayonet locking enclosure provides an easy and secured connection also under adverse conditions. The available materials for the housings are plastic, plastic metallized or nickel plated zinc die-cast for extreme harsh conditions. The LC connections are available for single mode or multimode transmission, depending on the requirements of the operated system. The major application for these connectors are connections from base stations to the transmission modules based on antenna poles or for network connections on the last mile into end users homes. This program is supplemented by preassembled patch cables in various lengths.

Request for a quote

STRONG MAGNETS GMBH

Germany

1. A deep cylindrical permanent magnet assembled concentrically in a mild steel pot with spacer of Aluminum or Copper. 2. These magnets are primarily for gripping applications. 3. Magnet material used is Alnico 5, working temperature is up to 250 ° C. North polarity in center of holding face and each magnet has a coated keeper 4. Outer surface except pole can be red (smooth or wrinkle) painted, or coated with Zinc, Nickel or Chrome We have accumulated abundant experience and established stable and credible business relationships with customers worldwide. With rich experience in dealing with all types of large and small orders, we have developed extensive contacts with many local and international freight organizations. Consequently, we are able to ship our goods safely and reliably to almost anywhere in the world

Request for a quote

FRIMO GROUP GMBH

Germany

"Combi" tools allow different technologies to be combined in a single step (in one tool) for more efficient plastic component production. Typical technologies applied in combined processes (depending on the requirements) are foaming, forming, laminating, edge folding, punching and joining. These processes allow different materials and material combinations to be used. "Combi" tools enable a very fast and cost-effective production process with minimized space requirements. Based on their longtime expertise and completion of numerous serial projects, FRIMO is able to supply optimized tooling solutions that perfectly meet the product and customer requirements. These range from small tools to special tools for large components for a nearly unlimited range of plastic applications. Our tools are available in steel or cast steel, as well as in aluminum, cast aluminum or nickel shells. For special applications, FRIMO also offers tools with interchangeable inserts, allowing the most efficient

Request for a quote

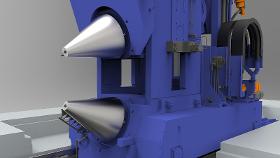

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

With the ring rolling mill Siempelkamp completes its range of products for the manufacture of rings. From forging the pre-forms to manufacturing the ring blanks to ring rolling, we supply everything from a single source. Siempelkamp’s ring rolling mill manufactures seamless rings made of steel and special materials such as nickel-base, titanium, or aluminium alloys using maximum radial and axial pressing forces. The radial pressing force is hydraulically generated and applied to the part via a mandrel roll. Radial rolling is carried out by reducing the roll gap between the driven external roller and the mandrel roll. The axial pressing force is also hydraulically generated and applied to the part via the upper axial roller. Axial rolling is carried out by means of the vertical forward feed of the upper axial roller. A centring device provides for the correct position of the ring during the rolling process.

Request for a quote

HYDROSTAR MESSTECHNIK GMBH

Germany

Air exchange in sealed housings? No Problem! Our pressure equalisation elements (formerly Gothe & Co. GmbH) have proven themselves reliably worldwide. High temperatures and adverse environmental influences provide continuous pressure fluctuations in sealed housings – protect your sensitive electronics and improve the lifetime of electronic devices with our pressure equalisation elements. Reliable reduction of condensate formation Protection of harmful fluids and particles Special Features Flat construction Easy installation (from inside or outside) 100% Salt retention capacity Very robust Diverse versions Air passage of up to 400 ml/min Technical Data Mounting body/cap brass (optional nickel-plated, chrome-plated or stainless steel) Membrane ePTFE (oleophobic) O-Ring NBR (optional EPDM, FKM or silicone) Water ingress pressure > 0,6 bar Protection class DIN EN 60529 IP66, IP68 (installed) Acceptable temperatures - 40 °C … + 80 °C (150°C temporary)

Request for a quoteResults for

Nickel ores - Import exportNumber of results

12 ProductsCompany type