- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mixing

Results for

Mixing - Import export

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

Lödige DRUVATHERM® reactors are batch reactors. Rotating mixing elements adapted to the specific process, installed in a cylindrical drum equipped with a temperature control jacket, create a three-dimensional product movement. The resulting contact frequency of the reacting agents with each other leads to a more effective conversion with a higher yield. The mixing elements ensure high contact frequency of the reacting agents with each other and intense contact of the reacting agents with the heated or cooled vessel wall. This makes reactions in homogeneous and heterogeneous phases possible in practically all combinations (solid/liquid/gaseous). The production consistency can be anywhere along the spectrum of liquid to pasty to lumpy to pourable. High-speed rotating choppers installed on the side of the machine drum perform additional mixing work to distribute the reacting agents.

Request for a quote

ELKON GMBH

Germany

Being produced in ELKON’s latest tech production facilities, mobile continuous mixing plants (pugmills) can be easily transported via axle and tyres installed on the main unit. Thanks to its superior mobile design, these plants are installed on a flat concrete surface without foundation requirement and can be relocated easily so that the user doesn’t have to travel long distances for material transportation. These mobile pugmill plants are mainly used for for subbase (stabilization) material with / without cement production and RCC concrete for dam or road pavement projects. Mobile continuous mixing plants, also known as WOLF in ELKON’s product range, are equipped with 5000/2500 l. ELKON continuous twinshaft mixer. All materials are mixed passing through ELKON C200 mixer continuously according to the recipe and flow speed.

Request for a quote

ELKON GMBH

Germany

Being produced in ELKON’s latest tech production facilities, stationary continuous mixing plants (pugmills) are mainly used for subbase (stabilization) material with / without cement production and RCC concrete for dam or road pavement projects. Equipped with 5000/2500 l. capacity ELKON continuous twinshaft mixer, there two models of pugmill plants, 300 tons/h and 500 tons/h capacity. In this mixing plants, thanks to aggregate bins equipped with dosing belts, it’s possible to adjust material flow rate by means of frequency inverters. Cement flow rate can also be precisely adjusted by a screw equipped with frequency inverter whilst the water flow by a proportional valve. All materials are mixed passing through ELKON C200 mixer continuously according to the recipe and flow speed.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The high-shear mixer is a system for mixing, granulation of pharmaceutical powders and granulated products. Moreover, it is suitable for a wide range of cosmetics and food products. A three-bladed mixing tool rotates in a vertical, cylindrical mixing vessel close to the wall and to the bottom of the vessel. The shape and peripheral speed of the mixing tool create a vortex-like circulation of the mix. A separately driven chopper is used for breaking up agglomerated products as well as for moistening and granulation. Liquid addition is either gravimetric or uses a pump to add liquid directly to the effective range of the chopper, so that the best possible distribution is ensured. The optional wet sieve on the discharge ensures a completely homogeneous distribution of the granulate size. The PC/PLC-based control system to be compliant with CFR-21 Part 11. The updated user interface permits intuitive machine operation in service and automatic mode for production and cleaning operation.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The laboratory model supplements the well-established Lödige mixing granulator range. The laboratory mixing granulator permits the same process steps as the production machines: — Mixing — Moistening — Granulation — Temperature control (using double jacket) The laboratory mixing granulator is delivered operation-ready with a CE conformity declaration. For the sizes, please refer to the machine flyer. A three-bladed impeller rotates at the bottom of the vertical, cylindrical mixing vessel, to create a vortex type of circulation for the material to be mixed. Very short mixing times and excellent mixing quality are achieved, even if the product components are extremely different. The separately driven chopper (only for the 5, 10 and 15 l vessel) is designed for breaking up of agglomerated material, for uniform moistening, wet granulation and streak-free mixing of dyes, as required.

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

GRUNDODRILL 4X GRUNDODRILL 11XP GRUNDODRILL 15XP GRUNDODRILL 15XPT GRUNDODRILL 18N GRUNDODRILL 18ACS GRUNDODRILL 28Nplus Mixing units Mixing unit MA07 Mixing unit MA09 Mixing unit MA010 Accessories Used Machines

Request for a quote

ELKON GMBH

Germany

The latest design of ELKON innovation team, ELKON MIX MASTER-30 On-site Concrete Batching Plant, makes it possible to produce concrete wherever needed according to international standards in a very economical way even for small projects that require relatively small quantity of concrete. ELKON Mix Master-30 On-Site Concrete Batching Plant which can be ready for concrete production within 1 hour in wherever concrete is required, provides the following advantages - Quick installation without crane and quick relocation (only 1 hour) - No need for any concrete foundation - Installation on a very small space - Transportable by towing on roads - Cost effective shipping to overseas (can be fit into 1 unit 40’OT Container along with the bag cement feeding system) - No permission required for concrete production - Allowing concrete production on site, significantly reduces the concrete transportation cost - High quality and precise concrete production

Request for a quote

DRESSLER GROUP

Germany

DG Mixing process which under the application of high speeds injects enough energy into a powder quantity to create a stable compound from different types of powders and grain particles. Used, for example, for coating surfaces of one type of particle with other particles.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Mixed alumina type WIWOX® RK has a low ferrite content and is particularly suitable for applications where a high consumption of blasting abrasives cannot be avoided. Mixed Alumina is produced from ceramic grinding wheels and reclaimed alumina dust from the blasting and grinding industry. It consists of a mixture of white, pink and brown alumina, and is an iron-free alternative for many sectors of the blasting and grinding industry.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The ploughshare mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate to the wall. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. All the product is constantly involved in the process, ensures a maximum mixing intensity and shortest residence times until the product is discharged out of the mixer via an outlet. Thanks to their form adapted to individual application and the speed adjustment, Lödige ploughshare mixers can be used for a wide range of applications. Choppers can be additionally installed in the mixing drum to increase the turbulence in the mixing process. This ensures the mixing of fine particles in small quantity and enables the dispersion of these products.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The continuous ploughshare mixer uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. The mixing elements having a defined shape and a special arrangement on the shaft, they ensure not only a reliable product conveyance but also a sufficient back-mixing of the product. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. The continuous process can be run at filling levels between 20 % and 50 % without influencing the mixing quality. Choppers can be additionally installed in the mixing drum.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The ploughshare mixer for batch operation uses the mixing and fluid process introduced to mixing technology by Lödige. The ploughshare shovels on the mixing shaft in a horizontal, cylindrical drum rotate to the wall. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. Thanks to their form adapted to individual application and the speed adjustment, Lödige ploughshare mixers can be used for a wide range of applications. Choppers can be additionally installed in the mixing drum to increase the turbulence in the mixing process. This ensures the mixing of fine particles in small quantity and enables the dispersion of these products .

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The application range includes everything from processing of viscous components to paste-like products with poor flow. The range of food applications is exceptionally broad and there are also various applications for the pharmaceutical industry. The conical shape permits thorough residue-free discharge. The wet mixer system is a vertical mixing system for batch processes. The geometry of the conical or cylindrical mixing vessel, the arrangement and shape of the tools and their peripheral speed are adapted to each other in all sizes, resulting in effective mixing of all components. Depending on the process engineering tasks, the individual mixing tools are combined to form one tool both for material transport and for dispersion and disagglomeration processes. The installation height in the vessel is adjustable within a wide range. An adjustable deflector can be used to affect the product movement in a systematic fashion.

Request for a quote

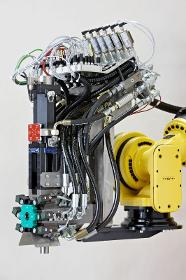

JERKO-SPRÜHSYSTEME GMBH

Germany

Developed to optimize the service life of warm forging presses with internal cooling of the work piece. Based on the extremely reliable high-pressure valves of the JB series, we have designed a completely dead space free valve block for internal tool cooling. High cross sections and an optimal atomization provide a powerful spray jet and increase the service life of your dies. Compact design, low maintenance and the modular system allow an easy conversion of your half-hot line. With our system, we have already been able to convert over 20 presses from outdated valve technology to modern spray mixing blocks. We have always been able to confirm the numerous advantages to our customers. Do you have problems with your spray system on a warm forging line? Then do not hesitate and contact us!

Request for a quote

FRIMO GROUP GMBH

Germany

The right mix From basic to high-tech, FRIMO offers peripheral equipment for all PU processing technologies.

Request for a quote

FRIMO GROUP GMBH

Germany

FRIMO PURe Mix mix heads are available as two-component or multiple-component mix heads for various PU product manufacturing. Different sizes for the smallest and the largest output rates are available. FRIMO offers a patented PU spraying system for the production of high quality PU surfaces, such as for automotive interiors.

Request for a quote

FRIMO GROUP GMBH

Germany

The right mix is what counts. FRIMO offers tailor-made mix and metering machines including various standardized modules for PU product manufacturing.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MIXACO MASCHINENBAU

Germany

MIXACO Container-Mover The container mover enables simple and quick transportation. You will also receive a battery charger in the scope of delivery. The advantages at a glance •Forward and backward movements of the container that do not strain the head due to heavy-duty electric drive •Simple handling •Handle with height adjustment •Adjustable speed •Self-engaging coupling for quick coupling and decoupling without tools

Request for a quote

MIXACO MASCHINENBAU

Germany

The mobile stainless steel MIXACO container equipped with wheel s is filled with raw materials and then pushed towards the container mixer by the operator. In this pha se, the container is used as a transport container. In the container mixer, the container is connected t o the mixing head and tilted 180° into the mixing position. During the mixing process, the container together with the mi xing head is therefore used as a mixing chamber. After mixing, the container is tilted back to the basic position. The container with the fi nished mixed material is removed from the mixer, and can now be transported directly for further processing without decanting to a diff erent receptacle. In this phase, the container is once again used as a transport container.

Request for a quote

MIXACO MASCHINENBAU

Germany

Gentle Mixing Without Tools MIXACO Revolution™ is mixing system that functions without tools. Gentle mixing of materials during rotation of the container is achieved with built-in mixing segments. This technology without driven mixing tools prevents additional thermal stress for the product. All Benefits at a Glance •Gentle homogenization •No inadvertent warming of mixing materials •No abrasion of granulates •Double-walled mixing vessel allows temperature-controlled mixing •Energy-efficient through low drive power consumption •100% discharge by pivoting to discharging position •Good accessibility for fast, easy cleaning •Tool-free design makes maintenance easy •Suitable for ATEX applications (up to Zone 20 without inertization of protective gases)

Request for a quote

MIXACO MASCHINENBAU

Germany

MIXACO Charging station The MIXACO charging station is used for dust free filling of the mixing container with raw materials. In conjunction with a bottom weighing scale or dosing systems, a fully automatic, a semi-automatic or manual charging of the container can be carried out.

Request for a quote

WESTMARK GMBH

Germany

• high quality beech wood spoons in different sizes (25, 28, 35 cm)

Request for a quote

WESTMARK GMBH

Germany

• from high quality polyamide • ideal for coated pots and pans • heat resistant up to 210°C / 410° F

Request for a quote

WESTMARK GMBH

Germany

• two piece lid and pouring spout (strainer-function) • scale in DE, GB, FR • measures: ml, liter, pints for liquids and grams • non-skid ring at the bottom

Request for a quote

WESTMARK GMBH

Germany

• dividable lid serves as splatter guard - and with the center seal as storage lid • with pouring spout • with non-slip ring at the bottom

Request for a quote

WESTMARK GMBH

Germany

• dividable lid serves as splatter guard - and with the center seal as storage lid • with pouring spout • with non-slip ring at the bottom

Request for a quote

LEROMA GMBH

Germany

Potato starch is used as a thickening agent in a variety of food products, including soups, sauces, and baked goods. Its ability to bind water is an advantage here for food manufacturing and product development. Potato starch is also used as a binder in the production of sausages and as a stabilizer in dairy products. Potato starch can be used in the following products: Dough products such as bread, pasta, cookies, and also in other products such as candy, canned vegetables, meat products, convenience foods, and as animal feed.

Request for a quote

ECO KUNST GMBH

Germany

Our Rugs & Carpets are made of 100% Jute & Cotton. which is highly durable and eco friendly. We are producing high quality hand woven rugs with certified responsibilities. Our factories are Fairtrade, BSCI certified.

Request for a quoteResults for

Mixing - Import exportNumber of results

29 ProductsCompany type

Category