- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metals and alloys

Results for

Metals and alloys - Import export

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

pressure equipment: valves, boiler systems, piping PED 2014/68/EU, AD 2000-W0, ASME/ASTM, CNIM, Alstom, MHPS nuclear power/ atomic energy and plant construction KTA3201.1, KTA1401, AVS D 100/50, Siemens, EDF/Areva/RCC-M naval architecture/ shipbuilding and offshore/ ocean engineering American Bureau of Shipping (ABS) Bureau Veritas (BV) Det Norske Veritas (DNV) Lloyds Register (LR) Nippon Kaiji Kyokai (ClassNK)

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material and create the desired shape. A wide variety of materials can be used in CNC turning, including:Aluminum, brass, bronze, copper, hardened metals, precious metals, stainless steel, steel alloys,ABS...

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Large Quantities: produced as cold formed parts (so-called multi-station presses), which require high output volumes in order to achieve a reasonable price parts Small Quantities: Produced as turned parts - the economic adjustment to small batch sizes Fields of application: For thermoplastics, duroplastics, light alloys, metal compounds. Industrial consumers: Electrical industry, plastics processing industry, sheet metal processing industry, telecommunications, tank- and container construction.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

We process the following materials: ■ chrome-nickel steel ■ various types of steel ■ non-ferrous metals ■ various aluminium alloys steel processing, stainless steel, machine engineering, tool engineering, metal processing, sheet steel processing, material 16 Mo3, Hardox, 1.4301, 1.4571, 1.4404, S355, S235, metal products, steel products, supplier construction machinery, power station, energy station, offshore equipment, pipes, steel halls, metal construction, profiles, handrails, balconies, stairs, roofing, pallet warehouse, pallet inverters, scrap conveyors, transport racks, special frames, devices, die blocks, barrel press, fork shoes, fork extensions, industrial gates, fences, customized constructions, industrial service, furnaces, playgrounds, sports fields, cladding, casing, housing, covers, noise-protection cabins, machine frames, large milled parts, conveyor technology, conveyor line, plunge pools, tank barrels and much more

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Stainless steel • Heat resistant steels • Cold and hot working steels • Hardened steel up to 1900 N/mm2 • Nickel based alloys • Aluminium-silicon alloys • Copper-nickel alloys • Titanium and titanium alloys • Exotic, hard to cut alloys

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TRAS MM

Germany

Email : trasmme@gmail.com SKYPE : TRAS MM ============================== ZINC INGOT Usage: Mainly used for die-casting alloy battery industry Pharmaceutical / rubber industry Chemical industries zinc and other metal alloy plating coating industry in applied widely. Factory with strong supply ability silver white lustrous metal zinc ingot for die-casting alloy battery industry 1. mainly used for melting ingot 2. discontinuous melting with scrap 3. Used for industry such as automobile,pinning and weaving,electron broadly and so on

Request for a quote

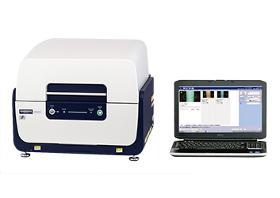

HITACHI HIGH-TECHNOLOGIES EUROPE GMBH

Germany

With this high-end spectrometer the advantages of a fast and precise 50mm2 SDD, a flexible and robust X-Ray excitation and a motorized XYZ-stage can be used to analyse a wide range of samples in fast, reliable and precise measurements. This includes for example (but not restricted to): - solids (like metal alloys, minerals, jewellery, electronic parts [PCB],…) - powders (minerals, ceramics, paint, soil,… ) in a corresponding holder - liquids (oils, solutions, paint, …) in a corresponding holder A Dual CCD camera system with wide view and high-magnification view enables a precise positioning of the sample easily from a big area to investigate exactly to region of interest you want to analyse. With the help of the optical system an easy navigation over the sample is possible and a laser-based auto-focus system ensures correct measurement position. Furthermore a second laser-system prevents collisions. The easy identification of areas containing targeted elements is possible by combi

Request for a quote

HITACHI HIGH-TECHNOLOGIES EUROPE GMBH

Germany

The use of XRF techniques enables a non-destructive analysis of nearly all kind of samples with almost no pre-processing. Already this basic spectrometer configuration allows you to analyse: - solids (like metal alloys, minerals, jewellery, electronic parts [PCB],…) - powders (minerals, ceramics, paint, soil,… ) in a corresponding holder - liquids (oils, solutions, paint, …) in a corresponding holder with respect to the latest restricted materials guidelines (like RoHS, WEEE, etc.) but also in a more general way to estimate the composition in an element range from Al (13) to U (92). A CCD camera is used to position the sample that only the area of interest is measured – with the use of suitable collimators a minimum spot size of 1mm can be realized. To enhance the measurement speed and analytical performance (energy resolution) the EA1000VX is equipped with a state-of-the-art 50mm2 SDD detector (no liquid Nitrogen needed anymore). This hardware allows you to analyse film thickness

Request for a quote

3S SIMONS SECURITY SYSTEMS GMBH

Germany

With SECUPRODUCT® we have developed a cross-industry solution for the direct marking of products. The micro colour-codes SECUTAG® form the basis of this solution. Spare parts in the mechanical engineering industry, in the automotive and aircraft industry can be secured against counterfeiting. From amplifiers to zips, SECUPRODUCT® enables the direct and legally binding labelling of originals. For an adequate product protection, the perfect adhesion to the product is decisive: SECUPRODUCT® is meticulously and precisely applied onto nearly all solid matters, among which metals, synthetics, paper products, glass, alloys and textile fabrics. For smaller productions and single pieces, the application can occur manually; for large serial productions, the colour-codes are integrated fully automatically into the existing manufacturing process.

Request for a quoteResults for

Metals and alloys - Import exportNumber of results

10 ProductsCompany type