- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal sheets

Results for

Metal sheets - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Mechanical parts.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

we process thin sheets, heavy plate, wear-resistant sheet and plate. aluminium sheets, stainless steel sheets, copper sheets, brass sheets and much more, with formates from 3000 to 8000 mm (118" to 315"), with thickness 1 mm – 180 mm (0,039" to 7") welded sheet metal structures, aluminium constructions, industrial profiles

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

This how each cut is made Sheet metal is available in a very wide range of materials and alloys. The criterion for machining is a given toughness and strength to make the metal sheets deformable. A part of sheet metal machining is separation by shearing, in which the sheets are divided by two shearing knives. For over 40 years, we have supplied shearing knives in lengths up to 4,190 mm in qualities and hardnesses specially matched to the purpose for the corresponding machines. By using peripheral grinding machines, we can comply with the tightest form and position tolerances, which is why so many machine manufacturers rely on the quality of our shearing knives.

Request for a quote

ROLLON GMBH

Germany

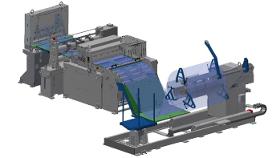

Versatile transfer system for metal sheet handling, designed as the main element in a series of presses which eventually combine with load/unload systems. The system features high positioning precision with heavy duty cycles and high dynamics, and is also available for very extended lengths. It manages cantilever loads to keep one side of the series free for operations. The system is driven by a belt with Ω transmission. The Z axes can be placed at different distances, according to the loads. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

GSW SCHWABE AG

Germany

The Combination Slitting & Cut-To-Length Lines are probably the most flexible coil processing lines within the field of cutting. By combining the cutting lengthwise and across, the coil material can be processed into a variety of blanks. So, if your production features a limited number of different coils as basic materials, while the variety of widths and lengths of the blanks is high, a Combination Slitting & Cut-To-Length Line will be the right choice. The system bases on the Cut-To-Length technology while offering the additional functionality of slitting. Since the slitting technology is home-made too, we can provide a fully integrated solution. An incisive experience so to speak. As a sizable advantage, storage space and material costs per ton are both significantly reduced, and with Combination Slitting & Cut-To-Length Lines even smallest batches can be delivered immediately.

Request for a quote

SPANSET SECUTEX GMBH

Germany

The prongprotection tubular module optimally protects sensitive, round loads. It is extremely wearresistant, strong against slippage, and easy to exchange. The prongprotection tubularmodule is easily pushed onto the existing mandrel and affixed with the end cap. The individual sections can rotate freely to accommodate any movement of the load and reduce wear.

Request for a quote

SPANSET SECUTEX GMBH

Germany

Make your forklift even more flexible with the a secutex prong protection coil. After you have secured everything for careful transport, back the lift prongs out of the secutex prongs protection coil and continue to use the forklift normally. Mounting various prongs can be omitted. The secutex prong protection coil is carried by both prongs. The secutex protective coating avoids material damage and prevents the coils from slipping.

Request for a quote

SPANSET SECUTEX GMBH

Germany

secutex prongs are selected when products and good must be securely and carefully transported on a consistent basis. secutex impact protection is especially wear resistant, noise cancelling and dampening. It is approved for prolonged use. As part of this design, the fork prongs and fork shanks are permanently coated with secutex impact protection.

Request for a quote

SPANSET SECUTEX GMBH

Germany

The design offers optimal protection to goods that stick out from the edges of the palette, for example. The secutex coating is inseparably connected to the fork shank. The perforated plate prevents the fork prongs from detaching.

Request for a quote

SPANSET SECUTEX GMBH

Germany

secutex prongs are selected when products and good must be securely and carefully transported on a consistent basis. The design offers optimal load and liftingdevice protection in situations with limited space. The secutex resistant coating is inseparably connected to the fork prongs and the perforated plate prevents the fork prongs from detaching. A crossbeam on the tip of the fork prong prevents the secutex coating from detaching.

Request for a quote

SPANSET SECUTEX GMBH

Germany

The fork extension offers all the advantages of the secutex coating. Because it is welded, it is especially robust and sturdy as well as noise absorbent and slipresistant. It can be simply pushed onto the prongs and secured with a bolt and cotter pin without tools.

Request for a quote

J.D. GECK GMBH

Germany

Double hooks are suitable for the presentation of goods in clear and blister packaging. The top bar and cross pin can carry scanning pockets, price labels or electronic price labelling as required. The snap lock is designed for perforated walls with euro holes. Goods carriers are our core competence and are available in many variants length, wire and material thickness, back wall system and surface can be selected almost freely.

Request for a quote

SPANSET SECUTEX GMBH

Germany

Standard design; open at bottom The SZGVO is an ideal extension that is very light. As with all forkprotection products, the SZGVO can be outfitted with a secutex buffer pad. The thickness and width of the fork extension are based on prong width, prong thickness and carrying capacity.

Request for a quote

SPANSET SECUTEX GMBH

Germany

Fork extensions are the ideal solution where loads need to be transported that are longer than the fork prongs. Please note The extension must be supported by at least 60% of the existing fork prong. The carrying capacity of the fork extension is dependent on the particular fork. Please pay attention to the carrying capacity and centre of gravity of the forklift truck.

Request for a quote

SPANSET SECUTEX GMBH

Germany

Required protection according to StVZO What is required on public roads cannot be wrong in factory traffic! If the forklift is driven on public roads without load, then the use of a warning bar is prescribed according to StVZO. The secutex warning bar is attached onto the two prong tips and simply secured against the forklift’s shield with the permanently mounted lashing straps. The warning colour yellow and the black warning crosshatching make the bar very visible. And should something be bumped; the elastic secutex material distributes the impact over a wide area and thus avoids possible damage. Option with reflective warning foil and magnetic attachment

Request for a quote

SPANSET SECUTEX GMBH

Germany

The design provides protection for the load and lifting device at very low retraction heights. The fixed coating is inseparable from the fork prongs. A crossbeam at the tip of the fork prong prevents the secutex coating from peeling.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GSW SCHWABE AG

Germany

A perfect combination of space savings and dynamics: the GSW Compact Feed Lines Our Compact Feed Lines are an ideal answer to the challenge of a constraint floor and necessity to process thick materials. Marrying the processes of leveling and indexing into one Feeder-Straightener machine allows for a complete Feed Line with only two individual machines and thus greatly reduces the necessary length. Additionally, the decoupling of the coil mass from the indexing process – achieved through a short loop between Coil Reel and Feeder-Straightener – enables dynamic feeding despite the compact footprint. And, if cross-sections are especially big, the loop can be spared completely, creating yet more space. One more advantage, virtually a by-product out of their very nature, is the quicker set-up of our Compact Feed Lines. This elevates them to not only space- but also time-savers!

Request for a quote

SPANSET SECUTEX GMBH

Germany

secutex – the gentle power against raw impact forces. If screwing or welding is not possible, just glue the secutex where impact protection is required. No problem with the secutex special bonding material. These are the advantages by gluing (nearly) everywhere applicable No drilling or welding necessary Bonding where welding or screwing is impossible Applications Thin to medium thick wood plates Glass and plexiglass Sound absorbing elements Fine wood surfaces Examples Coolhouses Painted, laminated, veneered walls and surfaces According to special requirements A proper bond requires always a good preparation … The following procedure is needed 1. Cleaning of the surface Suitable grease and siliconedissolving cleaning agents are required. This step is important to ensure that there is no dirt on the surface which may be present during the grinding or sandblasting process. 2. Roughening the surface Sandblasting or grinding of the surface are especially suitable here.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The versatility and and capability of LAWECO products is most notably shown in coil processing systems. In the infeed and outfeed areas, coil lifting carriages primarily handle the coil. In conjunction with various rack systems even complete solutions can be realised. In the stack areas, stationary and movable scissor lift platforms provide the required handling. Here, it is also our goal to respond to the wishes and requirements of our customers and to provide individual solutions. Coil weights up to 50 t With prism construction or support rollers With tilt-over protection tailor-made hydraulic group With materials handling technology, turntable / special construction With integrated weighing technology With special travelling gear With individual safety systems

Request for a quote

GSW SCHWABE AG

Germany

If you need two Coil Reels to hold one coil, you need a Heavy-Duty Coil Feed Line above all. One that is designed extremely robust and knows to subdue even materials of highest bounce and largest cross-sections.To ensure this, we have taken no heed to cost savings but went by the maximum principle: 2 Coil Reels with high-performance arbors retain the coils from left and right. 2 x 2 hydraulic arms secure them from top and bottom – each with eight tons pressure force, each with hydraulically driven snubber roll. The loading is done with one central lifting gear built into a super-duty running frame for the V-nest. Hydraulic manipulators with pivoting and bending function support the threading of the material. On the receiving end, a Pre-Straightener with 200mm work rolls takes over, after hydraulic edge guides have ensured central entry. Now, if someone asks us our definition of “heavy-duty”: We find 36.000 kilogram coil weight and 2.

Request for a quote

GSW SCHWABE AG

Germany

With Conventional Feed Lines, the focus lies on speed and material surface. That’s why Conventional Feed Lines are equipped with a Coil Reel for pull-off, a Straightener with variable frequency drive a coil loop and a Servo Roll Feed: the loop uncouples the more inert straightening process from the highly dynamic indexing process and thus allows for high line speeds and preservation of the material surface. Since productivity and capacity demands can vary significantly, we have created different control concepts: while small Feed Lines work with a simple pneumatic drag brake at the Coil Reel and an ultrasonic sensor to control the Straightener speed, the large Feed Lines get fully synchronized controls with motor-limited Coil Reels and a smart loop, creating a steady average speed of the whole line. This allows smooth pull-off of high coil weights while the loop remains very calm – in addition, the Servo Roll Feed can work with full dynamics, even at long indexing progressions.

Request for a quote

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

GSW SCHWABE AG

Germany

When you deal with industrial surface treatment and your expertise is the cleaning, brushing, polishing or coating of strip steel, you most likely do not want to spend any worries about the run of the material. That’s where our Winding Lines keep your worries away – because they take care of a safe run! They work with high tension and special monitoring and deflectors to do this, with the result of a clean wound beginning to end. The machine design thus calls for especially high drive power and precision expansion systems; even something so simple as the machine base is designed special to cope with the forces… To control the precision of one layer to the next, we utilize external edge controls and servo-drive the Reels for adjustment. This way we meet the typical low tolerances in this industry – after all, the coil is the product!

Request for a quote

SPANSET SECUTEX GMBH

Germany

Plastic for welding … Welding is often the simplest and best way of fastening. The range of different perforated plates offers a wide range of applications. Size and quantity of the welding joints depend on the substructure and must be defined on site. Please note that the perforated metal sheet can under no circumstances take over any static functions. The secutex buffer pad is simply disconnected by grinding away the welding spots. These are the advantages Simply weld onto the item to be welded No need for repeatable holes in the workpiece No holes in the secutex impact protection material Applications On all metal surfaces On thin metal walls Everywhere where screwing is not possible or screw holes are unwanted Examples Collecting basins Ramp protection metal boxes Container Forklift Gripper Girder protection Pallet truck 1. Perforated metal sheet, overhang at the side This version is suitable for welding onto flat surfaces and extrawide profiles of construction steel.

Request for a quote

SPANSET SECUTEX GMBH

Germany

secutex Impact Protection for screwing This is our top seller – secutex buffer pad with a perforated plate. Easy and flexible to use and can be fixed reliably with the perforated plate as reinforcement. In this way, you will have a universal impact protection in a short time. Size and quantity of the drill holes depend on the substructure and must be specified on site. Selection of the screws We recommend screw sizes up to a maximum of 6mm, any larger dimension does not provide additional strength in combination with the castin perforated plate. As screws we recommend hexagon socket screws with low head according to DIN 7984 or DIN 6912. Not recommended Countersunk screws; inefficient transfer of the force into the impact protection, Bolts with hexagon head; the nut grips the bolt on the outside, the borehole must be much larger for this. Normal screws with hexagon socket; the screw head is significantly higher, the impact protection must be thicker

Request for a quote

SPANSET SECUTEX GMBH

Germany

The secutex material may be sawn using a conventional band saw. The material will attempt to resist the cutting tool. Use as low a wedge angle as possible and, if necessary, adjust the cutting speed.

Request for a quote

SPANSET SECUTEX GMBH

Germany

“Heat”resistant buffer pad For hot processing. Nonferrous metals, such as gold, copper or brass, get hot during processing and have a sensitive surface. Rollers and cylinders coated with secutex Heat protect bar stock during production; abrasion and run marks are reliably avoided. Operating temperature up to 140°C Apart from the positive mechanical and chemical properties, secutex Heat is an elastomer material for operating temperatures up to a maximum of 140°C. Operating temperature up to 180°C As an option, „Heat“ can be finished with an aramide fibre surface. The operating temperature thereby even increases to a maximum of 180°C.

Request for a quoteResults for

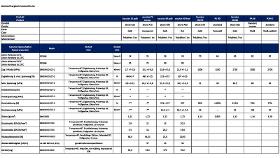

Metal sheets - Import exportNumber of results

53 ProductsCompany type

Category

- Sheet metal and strips, tinplate (27)

- Sheet Metal & Tubes (9)

- Industrial sheet metal work (7)

- Metal straightening machines (6)

- Sheet metals - stamping (3)

- Coil winders (2)

- Steels and metals - forming and cutting (1)

- Forming - steels and metals (1)

- Bending machine tools (1)

- Internal transport systems (1)