- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal industrie

Results for

Metal industrie - Import export

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

we process thin sheets, heavy plate, wear-resistant sheet and plate. aluminium sheets, stainless steel sheets, copper sheets, brass sheets and much more, with formates from 3000 to 8000 mm (118" to 315"), with thickness 1 mm – 180 mm (0,039" to 7") welded sheet metal structures, aluminium constructions, industrial profiles

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Large Quantities: produced as cold formed parts (so-called multi-station presses), which require high output volumes in order to achieve a reasonable price parts Small Quantities: Produced as turned parts - the economic adjustment to small batch sizes Fields of application: For thermoplastics, duroplastics, light alloys, metal compounds. Industrial consumers: Electrical industry, plastics processing industry, sheet metal processing industry, telecommunications, tank- and container construction.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

Powder technology has a long history in various sectors such as the chemical, food, pharmaceutical and metal industries. Measuring the physical properties of powder is very difficult and each industry uses different assessment methods. The PD-600 powder measuring system is the further development of the PD-51. It can determine the physical properties of powder via resistivity. Powder materials of carbon products: Materials used for rechargeable battery electrodes, condensers and resistance material and insulating electronics / cokes / graphite / carbon black / carbon fiber / nano carbon, etc. Metal powder: Materials used for battery electrodes, thin film materials such as copper powder or ITO powder, for circuit board materials, for example conductive paste and electro conductive paint. Others: Thermoplastic powder, Printer toner, Magnetic material such as ferrite, food material, pharmaceutical related and automobile parts.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Economic and safe: Hydraulic bolt tensioning systems Single clamps or small clamps for opening and closing reactor pressure vessels or other primary circuit components As a specialist for the design, construction, supply and maintenance of highly automated bolt tensioning systems, we offer our customers demand-oriented solutions for opening and closing pressurized and boiling water reactors as well as other primary and secondary circuit components in nuclear power plants. Our range of services includes single and multiple bolt tensioning devices, bolt turning and handling systems, bolt and blind hole cleaning systems. Siempelkamp bolt tensioning machines reduce your operating sequences for opening and closing to less than 50 % compared to conventional methods

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

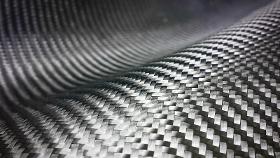

Pioneering partnerships: Networking in our industry Siempelkamp actively contributes to the development of the industrial use of composite components with funding projects, cooperations with universities and industry partners as well as memberships in associations. Current R&D topics are for example: the manufacture of large-area structural components for the aerospace industry the integral construction approach, which combines several functions in one componen the further development of thermoplast forming for the industrial process the production of hybrid components made of ber reinforced plastic and metal for the automotive industry Through our active cooperation in associations, we are shaping the future of composite production. As a part of the competence network CFK Valley e.V., we contribute with our experience to the construction of presses for the practical application of ber composite and other lightweight construction technologies in the aircraft and automotive industry.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

A press for all processes Beside the pressing systems for industrial production, Siempelkamp manufactures laboratory press systems – both “try-out” presses for laboratoryscale tests with a starting pressing force of 150 t as well as presses for “fullscale testing”. The laboratory press systems are designed for maximum exibility. With it, all processes of composite production can be investigated. For example, it can be investigated whether press technology is an economic alternative for “autoclave” processes. All processes SMC with glass ber or carbon ber RTM PCM Organo-sheet consolidation Thermoplast forming Hybrid forming Integrated molding and joining of hybrid materials All control methods Force control with position monitoring Position control with force monitoring Each process step can be individually dened and programmed: All relevant process data are recorded and displayed.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The SMC presses from Siempelkamp are designed in such a way that they can also be used for the RTM process. Short cycle times Since the SMC process is predominantly used in the production of high quantities, apart from precision, a short cycle time plays a important role. And since the compound material is chemically reactive, the time window for achieving an optimum surface quality is also small. The advantages of the Siempelkamp presses: they apply the force extremely quickly to the product, because they close at a very high speed decelerating just before reaching the end position. Depending on the level of automation, the tool change is done automatically – just 120 seconds later the next part can be produced! No stress The precise positioning of the ram plate ensures that the tools are precisely aligned to each other during the complete press stroke – not just on the last millimeters. Under all operating conditions the tools remain parallel.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Fiber-reinforced composites are in demand in all high-end industries in which light weight and at the same time high durability under dynamic load ensure competitive advantages Efficient and reliable press technology for fibre composite plants Whether glass fibre reinforced plastic (GRP) or carbon fibre reinforced plastic (CFRP): The valuable material is mainly used in application fields where weight reduction, fuel consumption,anti-corrosion characteristics and other stress resistency feauters are in focus. The name Siempelkamp also stands for solid and precise technologies in these presses and handling systems as well as for high flexibility due to its suitability for all composite applications such as sheet molding compounds with glass or carbon fibers (SMC), prepreg compression molding with short, long or continuous fibers (PCM), resin transfer molding (RTM), and thermoplastic forming.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Control cabinets form the technical "central nervous system" of every production plant. They supply machine and plant components with electrical energy, protect electrical circuits, control drives and network machines with the Internet. In addition, they act as an interface for all information on the current plant and processing status and link production exactly where processes need to be accelerated and efficiency increased. Our subsidiary ATR Industrie Elektronik GmbH is your competent partner for the construction of switchgear and switch cabinets. We supply a wide range of different versions based on all current national and international standards. Switchgear is used in almost all industries, in addition to the wood-based panel and metal industry, e.g. in the automotive sector, in turbine and compressor technology, in energy supply or also in cooling and air-conditioning technology.

Request for a quote

ARMACELL GMBH

Germany

FLEXIBLE NON-METALLIC COVERING FOR INDUSTRIAL INSULATION Arma-Chek R is a flexible covering system for elastomeric and other insulation material types. Especially developed for use in offshore and industrial environments. High performance acoustic insulation for a quieter environment

Results for

Metal industrie - Import exportNumber of results

13 ProductsCompany type