- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- measurement - equipment & instruments

Results for

Measurement - equipment & instruments - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accssories use for machines.

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

The key to the successful optimisation of compressed-air systems is data. The METPOINT® range of measurement equipment with sensor technology and monitoring provides the data base for the evaluation and assurance of the compressed-air quality and for the identification of hidden cost drivers. Our measurement equipment can also be employed for the extension of plants and for the early elimination of malfunctions. With our sensor technology, you can capture residual oil content, residual humidity, volume flow and pressure – constantly, faultlessly and with exemplary precision. Our Monitoring and Data Logging makes all the relevant data accessible to you and your employees at a glance, ensuring the safety of your processes and the quality of your products. In this way you can take your energy management and quality control requirements to the next level of success.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

The Loresta GX is used to measure conductors and semiconductors in the lower resistance range. Measuring range: 10^-4 – 10^7 Ω. It is used to measure the surface resistivity (Ω / □), the volume resistivity (Ω · cm), electrical conductivity (S / cm) in the low-resistance range. The Loresta-GX works according to the 4-pin measuring method. The method is based on the four-wire method and was developed to eliminate the influence of contact resistance. The measuring heads consist of four needle-like electrodes. To simplify the measurement method and calculate the correction factors, all four electrodes are at an equidistant distance from each other. Conductive Materials: Paints, pastes, paints, printing ink, Smart Textiles, Plastics, rubber Film materials, metallic thin films, metallised films, resistor pastes amorphous silicon / silicon wafer, antistatic materials, EMC shielding materials ...

Request for a quote

N&H TECHNOLOGY GMBH

Germany

The Hiresta – UX measuring device is used to measure semiconductors or non – conductors (insulators). Measuring range of 10^3 – 10^14 Ω . The Hiresta UX is specialised in measuring the resistance, the surface and volume resistivity of various substances and materials of all shapes and sizes in the high-resistance measuring range. For measurements related to the ASTM D257 / ISO 2951 / JIS K 6911 standard of: antistatic materials flooring materials paper, packaging materials paints, pastes, paints fibers, clothes, fabrics adhesives, greases glass, concrete, ceramics plastics, film materials, foils etc. Up to 2000 measurement results can be exported to USB memory stick The conductivity meter impresses with its compact design, a color 7.5 “TFT touch display and user-friendly menu navigation.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

Powder technology has a long history in various sectors such as the chemical, food, pharmaceutical and metal industries. Measuring the physical properties of powder is very difficult and each industry uses different assessment methods. The PD-600 powder measuring system is the further development of the PD-51. It can determine the physical properties of powder via resistivity. Powder materials of carbon products: Materials used for rechargeable battery electrodes, condensers and resistance material and insulating electronics / cokes / graphite / carbon black / carbon fiber / nano carbon, etc. Metal powder: Materials used for battery electrodes, thin film materials such as copper powder or ITO powder, for circuit board materials, for example conductive paste and electro conductive paint. Others: Thermoplastic powder, Printer toner, Magnetic material such as ferrite, food material, pharmaceutical related and automobile parts.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

For liquids in basic process applications The OPTIWAVE 5400 is a 2-wire 24 GHz radar (FMCW) level transmitter for liquids in basic process applications. It is particularly designed for continuous, non-contact level measurement in the chemical, petrochemical as well as oil and gas industry. It can be equipped with a PP Drop antenna for condensing atmospheres and corrosive media but features also Metallic Horn antennas. Due to its high dynamic range, the 24 GHz radar can measure distances up to 100 m / 328 ft.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Radar (FMCW) level transmitter for powders and dusty atmospheres The OPTIWAVE 6500 is a 2-wire 80 GHz radar (FMCW) level transmitter for demanding applications with powders in very dusty atmospheres. With its small beam angle, this radar is particularly suited for continuous, non-contact level measurement in high and narrow silos, hoppers or buffer storage containers up to 100 m / 328 ft. Due to the high signal dynamics of the FMCW radar, the level transmitter is ideal for low-reflective media, dust, uneven surfaces or tanks with obstacles. As it features a flush-mounted PEEK Lens antenna, there is no intrusion of the antenna into the tank.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Radar (FMCW) level transmitter for agitated and corrosive liquids The OPTIWAVE 7400 is a 2-wire 24 GHz radar (FMCW) level transmitter for liquids in harsh environments like tanks with agitators containing corrosive media. It is particularly designed for continuous, non-contact level measurement under extreme conditions prevalent in the chemical, petrochemical or oil and gas industry. The device features Metallic Horn antennas as well as PTFE and PEEK Drop antennas for measuring distances up to 100 m / 328 ft. The Drop antennas are perfectly suited for aggressive liquids in tanks. In applications with toxic and dangerous products, this radar device can be equipped with a Metaglas® second sealing barrier.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Radar (FMCW) level transmitter for solids from granulates to rocks The OPTIWAVE 6400 is a 2-wire 24 GHz radar (FMCW) level transmitter for basic applications with solids. This radar is designed for continuous, non-contact level measurement of stones, plastic granulates, coffee beans and other products in solids processing of various industries. The level transmitter features a Metallic Horn antenna as well as PP and PTFE Drop antennas. The Drop antenna design minimizes scaling and is unaffected by the angle of repose. Hence no need for expensive antenna aiming kits or purging systems.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Guided Radar (TDR) Level Transmitter for the nuclear industry This 2-wire loop-powered HART® TDR level transmitter measures distance, level and volume of liquids. Ist different versions, high resistance to radiation and seismic qualification make it the ideal TDR device for safety-related and non-safety-related nuclear applications. — Agrees with nuclear standards (e.g. ASME Section III, RCC-M) — Qualified according to IEEE Std 323, IEEE Std 344 and RCC-E — Remote converter can be installed up to 400 m / 1312 ft away from probe

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Radar (FMCW) level transmitter for liquids with hygienic requirements The OPTIWAVE 3500 is a 2-wire 80 GHz radar (FMCW) level transmitter for liquids in hygienic applications. It is designed for continuous, non-contact level measurement in the food and beverage as well as pharmaceutical industry. The device features a flush-mounted PEEK Lens antenna with a small beam angle and dead zone for precise measurement even in small and narrow tanks with agitators. It is equally suited for use on larger tanks up to measuring distances of 50 m / 164 ft. As the radar withstands process temperatures up to +150°C \ +302°F and pressures up to 25 barg / 362 psig, it can be used in CIP/SIP cleaning procedures. The OPTIWAVE 3500 offers a large choice of hygienic process connections. It comes with extensive device diagnostics as well as HART®7 communication.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

This involves a play-free electronic switching cam encoder (abbreviated to: NOCN) with two (At version 79 four) galvanically separated switching outputs (cams), which can be set by the customer and which are activated or deactivated depending on the relevant position of the drive shaft. An absolute mulitturn encoder with CANopen interface, adjustable parameters and an electronic switching cam module is realized in the compact housing. A separate controller unit monitors the function of the cams. The encoder's CANopen position signal and the switching outputs can be parameterised separately. The parameterisation (cam limits, resolution, measuring range a.s.o.) has to be verified to the NOCN via a checksum. This checksum can be calculated by a TWK program or the standard algorithm recommended by the CiA. After verification the device can be set operational.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

This involves a play-free electronic switching cam encoder (abbreviated to: NOCE) with a maximum of four galvanically separated switching outputs, which can be set by the customer and which are activated or deactivated depending on the relevant position of the drive shaft. A parameterisable multiturn absolute encoder with SSI interface plus the switching cam encoder printed circuit board with separate controller are integrated into the compact housing. The SSI interface can be preset, the code direction can be set and the switching outputs can be preset.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

This involves a play-free electronic switching cam encoder (abbreviated to: NOCI) with a maximum of four galvanically separated1) SIL2 switching outputs that can be set by the customer, and which are activated or deactivated depending on the respective position of the drive shaft. A parameterisable multiturn absolute encoder with incremental interface as well as the four switching outputs are integrated in the compact housing. The switching outputs can be preset. A special shaft design appropriate to the play-compensating measurement gear ZRS is available. The supply voltage, incremental signal and switching contacts are each galvanically separated from one another

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The inclinometer measures the inclination in the gravitational field by means of MEMS sensors (Micro-Electro-Mechanical-System) with subsequent digitisation and linearisation via controllers. It has a stable aluminium housing (optionally stainless steel) and is highly-resistant to vibration and shock. Casting measures in the housing lead to the achievement of protection class IP 69K. The NBT has a redundant MEMS sensor system, which is used to make a plausibility check inside the inclinometer. Only one position datum is output; the plausibility of this is checked using the second system's position datum. Is the deviation of the two systems higher than a certain value, the sensor will enter the failsafe state.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Registration of inclination in the gravitation field using MEMS sensors (Micro-Electro-Mechanical-System) with subsequent digitisation and linearisation via a controller. Data output is carried out via the CANopen interface or as an analogue signal. The inclination sensor has a stable aluminium housing (optionally stainless steel). Slots are available for mechanical alignment (up to approx. ± 7.5°). In the case of CANopen, one connector or one male/female connector combination can be selected optionally for connection purposes. Casting measures in the housing lead to the achievement of protection class IP 69K, e.g. for use under water.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Registration of inclination in the gravitational field by means of MEMS sensors (Micro-Electro-Mechanical-System) with subsequent digitisation and linearisation via controllers. MEMS sensors are integrated circuits manufactured using silicon bulk micromechanical technology. Double capacities are formed with the aid of moveable micromechanical structures. If these structures are deflected in the case of acceleration, e.g. gravitational acceleration (g), this results in capacity changes, which are registered and further processed using measuring technology. The output voltage follows the function U ~ g * sin α. In this case, the angle α is the sensor's inclination angle measured against the g-vector. These sensors measure precisely, have a long service life and are very robust. The measuring axes operate independently of each other.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TWK-ELEKTRONIK GMBH

Germany

This involves a play-free electronic switching cam encoder (abbreviated to: NOCA) with a maximum of four galvanically separated switching outputs (cams), which can be set by the customer and which are activated or deactivated depending on the relevant position of the drive shaft. A parameterisable multiturn absolute encoder with analogue interface plus the switching cam encoder printed circuit board with separate controller are integrated into the compact housing. The analogue signal and switching outputs can be parameterised separately using multifunction pins (MFP and PRE) in the connector.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

This involves a play-free electronic switching cam encoder (abbreviated to: NOCE) with a maximum of four galvanically separated SIL2 switching outputs that can be set by the customer, and which are activated or deactivated depending on the respective position of the drive shaft. A parameterisable multiturn absolute encoder with SSI interface and the switching cam encoder PCB with separate controller are integrated in the compact housing. The SSI interface can be preset, the encoding direction is adjustable and the switching outputs can be preset. A special shaft design appropriate to the play-compensating measurement gear ZRS is available. The supply voltage, SSI signal and switching contacts are each galvanically separated from one another.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Registration of inclination in the gravitational field by means of MEMS sensors (Micro-Electro-Mechanical-System) with subsequent digitisation and linearisation via controllers. The housing-based inclinometer (model NBN 65) has a stable aluminium housing (optionally stainless steel) and is highly-resistant to vibration and shock. One or two connectors/socket in the case of CANopen can optionally be selected for connection. Casting measures in the housing lead to the achievement of protection class IP 69K, e.g. for use under water.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Registration of inclination in the gravitation field using MEMS sensors (Micro-Electro-Mechanical-System) with subsequent digitisation and linearisation via a controller. Data output is carried out via the CANopen interface or as an analogue signal. The inclination sensor has a stable aluminium housing (optionally stainless steel). Slots are available for mechanical alignment (up to approx. ± 7.5°). In the case of CANopen, one connector or one male/female connector combination can be selected optionally for connection purposes. Casting measures in the housing lead to the achievement of protection class IP 69K, e.g. for use under water.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

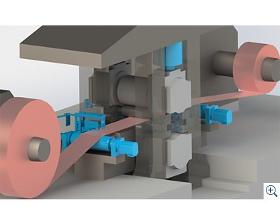

Proven for decades The contact gauges that measure the thickness of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible from 0.01 to 24 mm Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions for thicknesses from 0.01 to 24 mm. Precise even on wavy strip With a measuring precision of down to one micrometre per millimetre of strip thickness, they meet the demands of modern rolling mills. Contact gauges adapt to the strip passage and follow any waviness of the material.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

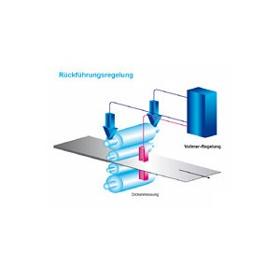

Efficiency thanks to flat strip The use of flatness measurement alone without control already achieves a noticeable increase in productivity because strip breaks can be effectively prevented or the mill can be operated at the maximum possible speed for the particular unflatness. If the mill has the necessary adjusting elements, the Automatic Flatness Control (AFC) results in an effective improvement in quality. Control results of ± 4 I-units referred to the respective nominal curve are realistic. With our detailed know-how of the interplay between measurement, control and rolling mill we are on of the few manufacturers able to supply complete control systems for the strip shape – from the sensor through to the control of the adjusting elements From the pivoting of the rolls through to the combination of pivoting, bending, shifting of the intermediate rolls and zone cooling and far more – we have a command of the whole spectrum of shape control.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness / width of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible for up to 9 mm strip thickness / 32 mm strip width Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions. Optional the strip thickness gauge can be equipped with an additional strp width measurement unit.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The high-speed servo-hydraulic control of the mill screwdown closes the loop: The thickness values measured precise to the micrometre form the basis for quick and precise control. Vollmer offers solutions for all control concepts from simple feedback control through to complete mass flow control or Direct gap contol for rolling of wedge-shaped strip and in tandem mills. Vollmer supplies the complete control system – from the sensors through the control technology right up to the hydraulics and the cylinder – from a single source. For our customers that means having just one contact partner – in short: A one-stop solution.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Thickness measurement on plastic film samples requires automatic transport of the film strips through the measuring device, allowing for the flexibility of the material being measured. The desktop version of the VDM measuring station can be equipped not only with the pure measuring device, but also with PC-aided evaluation and graphic representation of the measurement results.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The traversable straddle gauges are used for offline measurement. They are placed onto the roll and moved manually, thereby measuring the form of the rolls from crown edge to crown edge. They are characterised by a high measurement point density of 1 mm and a high repetition accuracy of ± 2 µm. With the evaluation software optimised over decades together with our customers for this application, curves can be pivoted and superimposed, centered and smoothed. The scope of supply also includes a panel PC.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

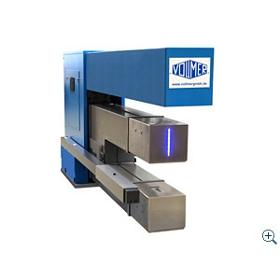

The new standard for precision and speed With the new VTLG Series laser systems, Vollmer is giving strip thickness measurement new impetus: They combine the highest precision with rolling mill-oriented design. Thanks to their unique measuring method, they are suitable for use in cold rolling mills. With a measuring precision of ± 1 µm and scanning rate of up to 80 kHz, they offer the precision and speed necessary for the control of the strip thickness. VTLG systems are the only laser gauges to measure the strip thickness during rolling in the mill, thus opening up completely new possibilities in production and quality assurance for our customers. As with our contact gauges, they measure the thickness irrespective of the alloy – ideal preconditions for use in the rolling mill, but also on the annealing line, in the finishing section, on the strip edge miller or in the steel service centre.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Precise even with low strip tension The segment rolls were developed specially for use in stretch bending levellers. The extremely free-running measuring rings permit high-precision shape measurement even with very low strip tensions. A rigid tubular section which forms the shaft of the roll supports several pivotably mounted measuring rings. They form the outer shell of the measuring roll over which the strip passes. Force sensors inside the measuring rings detect the force resulting from the strip tension. The sensors have high resolution, are overload-proof and maintenance-free. The data are transmitted through the centre axis of the roll and output as a Profibus signal.

Request for a quoteResults for

Measurement - equipment & instruments - Import exportNumber of results

43 ProductsCategory

- Measurement - Equipment & Instruments (37)

- Sensors (11)

- Measurement and regulation equipment and instruments - output and flow (10)

- Flowmeters (7)

- Weight and mass - measurement and regulation instruments (7)

- Measurement and regulation equipment and instruments - electricity and other energy (2)

- Measurement and regulation equipment and instruments - temperature (1)