- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mdf board

Results for

Mdf board - Import export

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

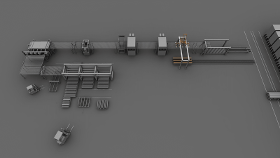

The stack of boards needs to be separated again for the subsequent processes. Siempelkamp provides process-reliable, dependable solutions for all products and board properties here. Features and functions Stack feeding using forklift trucks, aisle vehicles or conveyors Board separation and feeding from the stack by the highly dynamic Siempelkamp feeding system. Advantages Absolutely process-reliable for all products (e.g. MDF, particleboard, OSB), board thicknesses and lengths irrespective of the width Variants, options Buer for interruption-free feeding during stack changes Protection board handling.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

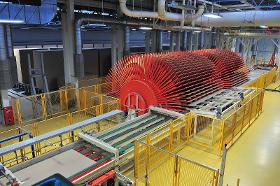

The PALLMANN rener system produces high quality bers from chips, saw dust, shavings, and annual plants for MDF, HDF, and insulation board production. PALLMANN supplies complete plants consisting of perfectly coordinated components to ensure the highest ber quality with minimal energy input. High quality ber production for MDF, HDF and insulation board plants with PALLMANN rening systems Chip bin for pre-steaming of chips: The closed design of the bin with downward tapering base is equipped with vibrating motors to ensure a continuous discharge. Circular steam injection results in perfect pre-tempering of the chips. Integrated load cells allow the online presentation of the lling level of the chips inside the bin. Plug screw: The extremely heavy and robust plug screw feeds the chips reliably into the digester and squeezes out excess water by doing so. The position compensation, caused by the thermal expansion of the digester

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The cooling section's design is optimised while taking account of the product's technological properties (particleboard, MDF, OSB), the range of board dimensions, production capacity and modes of operation. Siempelkamp is a system supplier and is so able to guarantee targeted coordination tailored entirely to the customer's requirements. The number of cooling turners results from the board dimensions and modes of operation Single-board operation moves a single board to the cooling turner and then triggers the turning cycle. The batch operation works with several boards in a row that are moved into the cooling section as one overall length before the turning cycle is triggered. The package operation mode works with several boards on top of each other that are moved as a package into the cooling section before the turning cycle is triggered. Option When the product widths vary greatly, an optional board pusher that slides

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Industrial Grate-ring systems are used very often in processes involving energy generation with solid fuels. Büttner's grate-ring energy systems are individually customized to the operator's needs and are exible when it comes to the fuel needed – whether it be waste wood, bark, or chips. Key features: fuels with a moisture content level between 20 - 150% based on bd combustion of waste wood (A1 - A3), wooden board wastes (MDF, PB and OSB), bark, wood chips, co air-cooled step grate sized from 12 to 90 m² ring capacity from 10 - 100 MW automatic de-ashing system graduated air-inlets low emissions

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Mdf board - Import exportNumber of results

4 ProductsCompany type