- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thickness gauge

Results for

Thickness gauge - Import export

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Thickness measuring systems THICK-SCAN behind the ContiRoll® optimizes the process and to reduces the costs while, at the same time, assuring the quality standard. If the gauges are located in the sanding line, the tool life of the sanding belts is enhanced and the quality is assured. The time is long past since panel thickness tolerances have been measured during production by handheld devices. Today, however, such measurement is carried out continuously online. In the majority of plants, quality control is not the rst priority for new investment for online thickness measurement. The current trend is to achieve the enormous potential savings in wood raw material, resin and energy consumption. If the upper tolerance level is exceeded, valuable resources are wasted. The Thickness Gauge prevents such losses. It is robust and reliable.

Request for a quote

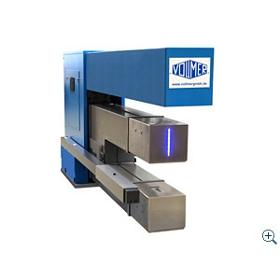

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible from 0.01 to 24 mm Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions for thicknesses from 0.01 to 24 mm. Precise even on wavy strip With a measuring precision of down to one micrometre per millimetre of strip thickness, they meet the demands of modern rolling mills. Contact gauges adapt to the strip passage and follow any waviness of the material.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness / width of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible for up to 9 mm strip thickness / 32 mm strip width Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions. Optional the strip thickness gauge can be equipped with an additional strp width measurement unit.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The new standard for precision and speed With the new VTLG Series laser systems, Vollmer is giving strip thickness measurement new impetus: They combine the highest precision with rolling mill-oriented design. Thanks to their unique measuring method, they are suitable for use in cold rolling mills. With a measuring precision of ± 1 µm and scanning rate of up to 80 kHz, they offer the precision and speed necessary for the control of the strip thickness. VTLG systems are the only laser gauges to measure the strip thickness during rolling in the mill, thus opening up completely new possibilities in production and quality assurance for our customers. As with our contact gauges, they measure the thickness irrespective of the alloy – ideal preconditions for use in the rolling mill, but also on the annealing line, in the finishing section, on the strip edge miller or in the steel service centre.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The radiometric gauges from Vollmer operate contact-free and measure from a safe distance. They are characterised by their extremely narrow design: With some systems the C-frame is only 120 mm wide. The X-ray systems from Vollmer have digital detectors which give them extremely low noise values. Vollmer supplies the systems with high-quality ceramic tubes and the necessary cooler. The isotope systems also have digital detectors. A particular feature of the Vollmer systems is that the radiation source is located in a special tungsten drawer that can be easily removed from the gauge. Alloy compensation is made either in the classic manner using calibration plates or alternatively at the computer according to the customer's chemical alloy analysis or simply with a small contact thickness gauge that measures the absolute thickness at the start of the pass and transmits this value to the radiometric thickness gauge.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Thickness measurement on plastic film samples requires automatic transport of the film strips through the measuring device, allowing for the flexibility of the material being measured. The desktop version of the VDM measuring station can be equipped not only with the pure measuring device, but also with PC-aided evaluation and graphic representation of the measurement results.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Thickness gauge - Import exportNumber of results

6 ProductsCompany type