- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- technological systems

Results for

Technological systems - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Quality at every level Safe transport and short throughput times — Lödige‘s material handling solutions easily accommodate all the demands made on them whether within the paint shop or in provision and intermediate storage after the painting process. Your advantages using Lödige solutions in the paint shop: Materials handling in multiple dimensions Connection to intermediate store Connection to body shell store Work stations Internal and external materials handling systems Materials handling systems and control technology from one source

Request for a quote

ROLLON GMBH

Germany

Versatile transfer system for metal sheet handling, designed as the main element in a series of presses which eventually combine with load/unload systems. The system features high positioning precision with heavy duty cycles and high dynamics, and is also available for very extended lengths. It manages cantilever loads to keep one side of the series free for operations. The system is driven by a belt with Ω transmission. The Z axes can be placed at different distances, according to the loads. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

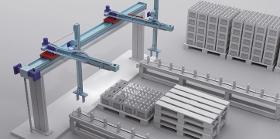

Multiple X/Y/Z Cartesian systems with belt, rack and pinion, screw, and hybrid handling. Utilizing the modularity offered by the full range of our linear actuators (Actuator Line), highly customizable Cartesian systems are available to meet the specific needs of our customers. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

IGUS® GMBH

Germany

The drive technology online configurator gives you the right drive technology system after you enter your requirements. You also have the option of requesting or ordering motors and other accessories, such as the motor control system. - Fast and easy configuration - Optional accessories - Detailed parts list - Fast delivery

Request for a quote

IGUS® GMBH

Germany

For designs that require a stepper motor with directly integrated lead screw, drylin® E offers the ideal solution. The stand-alone versions with NEMA11 stepper motor (very small type) are available in a compact type with or without encoder. The lead screw is centred and in combination with the dryspin® high helix thread technology, the system has a long service life. Stepper motors from igus® are a good supplement to drylin® linear axes. They are characterised by their cost-effectiveness, precision and easy control. They work reliably under the most varied environmental conditions (depending on the selected class of protection IP). The igus® stepper motors can be connected to the most common motor controls using standardised electrical connection. The encoder sends signals from the motor to the motor control. The encoder verifies that the required linear motion has occurred precisely as required. Encoder = increased machine accuracy.

Request for a quote

TRAPO GMBH

Germany

As a supplier of complete systems, TRAPO AG supplies modular High-Performance-Pick & Place-Systems that combine components such as robots, frame units, camera systems and conveyor technology. The modular system can be adapted to different framework conditions and thus covers almost any application. The TRAPO HPPS series forms the heart of the modular picker cell. The high-performance picker line combines maximum performance, individual TRAPO gripper technology and proven know-how, for example in the field of hygiene design.

Request for a quote

TRAPO GMBH

Germany

With decades of know-how and worldwide expertise in the core areas of conveyor technology, robot systems, palletizing, depalletizing and automation, TRAPO AG presents itself as a renowned manufacturer and total systems supplier of conveyor systems, palletizing technology and packaging machines. Primary and secondary packaging such as cartons, trays, pails and more are palletized and depalletized. The machines in our systems impress with their flexibility, high performance and economic efficiency. We produce in Germany and set standards worldwide ranging from engineering contracts to automation. The palletizers of the HLP series operate with high and low inlet. The product range of the high-capacity layer palletizers is optionally equipped with a y-axis, rotary module or even a traversing axis — so that one or more palletizing stations can be operated as required.

Request for a quote

HOPPECKE BATTERIEN GMBH & CO. KG

Germany

The trak | uplift impulse battery system offers decisive advantages over conventional lead-acid drive batteries. The high-current capability of the virtually emission-free AGM monobloc batteries ensures long runtimes in dynamic applications and short-term high loads. The integrated onboard charger provides even greater flexibility and availability. This is because the system can be temporarily charged at any standard socket. In conjunction with a HOPPECKE charger, up to 16% energy costs can be saved. Thanks to AMG technology, the system is completely maintenance-free, so there is no need to refill water over the entire service life. trak | uplift impulse is the perfect companion for truck-mounted forklifts and electric pallet trucks.

Request for a quote

GSW SCHWABE AG

Germany

HybridTechnology — just for automobiles? CompuSpray is the LubricationHybrid featuring a perfect addition to the PressSpray Technology, this system will allow selective spray lubrication while fully boxed in a stainless steel housing. Special brushes evenly spread the pulseactivated lube on the strop and prohibit any mist from exiting the system. Excess lube is collected and drained back into the reservoir. 45° angled entry or exit strip guide, made of stainless steel; to support threading if CompuSpray is mounted right after the Feeder GSW offers integration into its electrical controls system for intelligent choice of individual nozzles. this way, a minimal and exactly defined lubrication according to the feeding pattern is possible. The programming and visualization becomes part of the main PLC – for an unbeatable priceperformance ratio!

Request for a quote

ANTHERMO GMBH

Germany

Universal use for a wide range of applications Ice stores are used in more and more areas of technology. In addition to the classic areas of application in refrigeration, air conditioning and commercial kitchen technology, ice storage systems and cold water systems are increasingly being used in process engineering systems. Cold water for subsequent production processes is generated with ice storage tanks. Ice storage systems thus provide stored cold. Use of cheap night electricity tariffs With the help of ice storage technology, cheap nighttime electricity tariffs can be used. During the night, ice is continuously built up on the plates or on the pipe coils. This ice is then available during the day as stored cooling capacity. This can significantly reduce energy costs. The cooling units can also be made smaller when using ice storage systems.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

At our sites in Rothenburg/Saale, Hamm, Brandenburg and Nedri Industriedraht (Hamm), we manufacture iron and fabrication wire for the machine, plant and steel construction industry, shopfitting, displays, automotive, furniture industry, household goods, chains, blasting material, tool carriers, filter industry, fence construction, garden and landscape design, connecting elements, logistics, construction industry, electrical and cable industry, bent wire parts, household appliances and gastronomy, animal husbandry, welding technology, lightning protection systems, gabions, packaging industry.

Request for a quote

CRAEMER GMBH

Germany

The L3® is the ultimate heavy-duty plastic pallet for intralogistics applications. It impresses with a high load-bearing capacity of up to 2,000kg in high rack warehouses and with its slip resistance. The plastic pallet is equipped with Palgrip® anti-slip strips on the top deck as a standard feature, offering a secure hold even at an inclined position or in damp conditions, while the evenly closed Palgrip® anti-slip runners ensure absolutely smooth running on all standard conveyor technology systems. The L3® is long-lasting and remains maintenance-free. Dimensions L x W x H: 1200 x 1000 x 160 mm Weight: 26,0 kg Material: PE Load capacity: static 7500 kg, dynamic 2000 kg, In Racking System 2000 kg Reinforcement Profiles: 5 Colour: light grey / light blue or basalt grey / light blue Runners: 3, welded Palgrip® anti-slip strips on the top deck Palgrip® anti-slip coating under the runners Option: — Rim options: Without, 5 mm — RFID transponder

Request for a quote

CRAEMER GMBH

Germany

The EURO L1® plastic pallet is identical in construction to a wooden Euro pallet, making it a perfect plastic alternative for automated intralogistics. The heavy-duty pallet is extremely robust thanks to being injection-moulded in one-piece from high-quality PE. Durable, high quality guarantees that the EURO L1® is highly economical, even with increasing trip rates: The evently closed runners ensure the plastic pallet runs smoothly on all standard conveyor technology systems; the abrasion-resistant Palgrip® anti-slip strips on the top deck offer a secure hold for loading, even at an inclined position or in damp conditions. Dimensions L x W x H: 1200 x 800 x 150 mm Weight: 20,0 kg Material: PE Load capacity: static 7500 kg, dynamic 1250 kg, In Racking System 1250 kg Reinforcement Profiles: 5 Colour: light grey, light blue Runners: 3, welded Palgrip®-Anti-slip strips on the top deck Option: — Rim options: Without, 7 mm — Palgrip® anti-slip coating under the runners

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

The new UNI Dicht TRI achieves the highest shielding attenuation values over the complete frequency range and convinces with a very high current carrying capacity for the reliable discharge of undesirably high shielding currents. The installation is simple and safe: only the cable sheath has to be removed at the contact point where the shielding braid is to be contacted. As soon as the cable is inserted into the cable gland, the TRI spring makes reliable contact with the cable shield, even in the case of non-circular or off-centre cables. In any case, this type of contacting from PFLITSCH means that the cable shield does not have to be exposed until directly at the connection point in the control cabinet. Because the shielding braid remains 100% intact, maximum shielding attenuation is achieved and the useful signals are transmitted without unnecessary interference from noise signals.

Request for a quote

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

Junction systems are used anywhere sensor and actor signals need to be extended quickly and easly for connection to their superordinate control systems. Individual signals are either connected directly to the superordinate system via a homerun cable or via a connection interface. Optional LED displays for signal and power reduce the effort required to track down errors.

Request for a quote

FRIMO GROUP GMBH

Germany

Processing sound-absorbing materials such as textiles, carpets or foamed materials requires efficient and high quality system technology. FRIMO supplies tailor-made solutions for insulation and acoustic component manufacturing for vehicles or other applications which require noise-cancellation.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Discover the easy handling of our Pressure Transmitter and Reader of the PT-RF series. The PT-RF series of pressure transmitters are an alternative solution for universal pressure measurements for fluid technology applications, which will provide benefits for system operators, maintenance personnel and repair technicians as well as for original equipment manufacturers. The advantages resulting from the use of the new technology for system operators, maintenance personnel and repair technicians are clear: Measurements can be carried very easily, without extensive training and within a few seconds at the press of a button and then documented in a reliable process. Unscrewing and re-installing pressure gauges or other measuring and display devices – practically a temporary opening of the system – is not required. Potential hazards for people, machines and the environment, for example from emitted residual oil in the test hose or leaks at the measuring point, as well as ingress of...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The demands on production processes often change very quickly. VEN DRY VARIO TIME makes it possible to react quickly. The batch is detected by light barriers at the infeed and the dwell time in the dryer is controlled accordingly by the state-of-the-art control system. The special handling technology with sophisticated Venjakob control system exceeds your expectations for a powerful and flexible dryer concept. Loading locations: 38 Operating width: 1,300 mm Pallet length: 5,600 mm Useful length: 5,500 mm Loading per palletmaximum: 100 kg Item heightmaximum: 60 mm

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This machine has a twin cleaning unit, therefore it can be used for a dual application of water and solvent based paint systems. Reproducible results guarantee process reliability. The modular construction enables future expansion of the machine line and thereby ensures your investment for the future. Working width: 1,300 mm Working height: 920-960 mm Feeding speed: 3-8 m/min. Exhaust air volume: 7,000 - 10,000 m³/h Connect value: 20 KW Machine dimensions: 5,100 x 3,440 x 2,850 mm (L/M/H) The twin cleaning units of this flexible system technology enable a dual application for water and solvent based paint systems. The targeted paint-recovery by means of the patented V-belt system offers a maximum of profitability and environmental friendliness.

Request for a quote

ROTEG AG ROBOTER TECHNOLOGIE

Germany

The palletizing robot system PARO® has a modular structure. This is how the palletizing room can be optimally adapted to the palletizing task – even afterwards. The spectrum ranges from standard single place cells which are not bigger than the pallet itself, to palletizing systems with twelve or more palletizing stations. All of this is easily determined by a correspondingly long horizontal axis. The palletizing robot PARO® is a four-axis robot whose axis have a special guide system: Profiled, teflon coated Vulkollanrollers run on polished stainless steel tubes. This system has proven itself to be robust and maintenance free. With this simple system technology a lot of industrial handling processes are economically automated in different performance areas. The PARO® is durable and also suitable for the use in extreme enviroments. All in all the robot offers a good price-performance ratio.

Request for a quoteResults for

Technological systems - Import exportNumber of results

21 ProductsCompany type

Category

- Internal transport systems (2)

- Palletising machinery (2)

- Pallets (2)

- Goods handling systems, continuous (1)

- Automation - systems and equipment (1)

- Accumulators and batteries (1)

- Connectors, electronic (1)

- Electric motors and parts (1)

- Heat exchangers (1)

- Information technology - data processing media (1)

- Machine tools, metal shaping - parts and accessories (1)

- Robotics (1)

- Wires and cables, steel (1)