- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless steel sheets

Results for

Stainless steel sheets - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Mechanical parts.

Request for a quote

BORNEMANN GMBH

Germany

Stamp mouldings for embossed or recessed stamping of aluminium or stainless steel sheets for the car industry. We produce the stamp mouldings in accordance with your data in soft or hard condition. Thanks to the high-quality structures, the movement between top and bottom dies is precisely coordinated. The design is based on your drawings or data.

Request for a quote

ROLLON GMBH

Germany

Sturdy and practical galvanized or stainless steel linear rails with radial ball bearing sliders. The X-Rail is a family of linear guides with radial ball bearing sliders for applications requiring cost efficiency and high resistance to corrosion. The shaped raceway rail, the flat raceway rail and the telescopic rail are available in stainless steel or galvanized sheet metal. With the T + U configuration, the X-Rail system can compensate for any axial misalignment in parallelism of the mounting surfaces. Three rail width sizes: 20mm, 30mm and 45mm Standard rail lengths up to 3,120mm; different lengths upon request Low coefficient of friction Combination of T and U rails for self-aligning bearing applications Easily adjustable slider preload Polymer based wipers available for added roller bearing protection (available on for the thin body style slider) High temperature resistance up to 120°C/250°F The stainless steel X-Rail linear guide version is corrosion resistant, and ensures...

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

we process thin sheets, heavy plate, wear-resistant sheet and plate. aluminium sheets, stainless steel sheets, copper sheets, brass sheets and much more, with formates from 3000 to 8000 mm (118" to 315"), with thickness 1 mm – 180 mm (0,039" to 7") welded sheet metal structures, aluminium constructions, industrial profiles

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Device for automatically blowing the adhering water off after passing through the pretreatment plant. The rotary blow-off zone is a device for blowing the adhesive water off workpieces that have been washed for the purposes of painting. It consists of a closed stainless steel sheet metal housing with forced ventilation and is employed immediately after the washing installation. In order to achieve more effective drying in the case of fissured surfaces, the blower nozzles are arranged on a rotary axis. The adhering water is blown off by the parts by air blown at high speed through the rotary blower nozzles. The effect of this is that no water droplets remain on the workpiece that could lead to slight marks in the paint film. Due to the varying blowing direction, the water is also blown out of problem zones and scooped parts in most cases. In order to be able to optimise the direction of the blower nozzle air jets, the nozzles have adjustable nozzle heads. The water that is blown off runs back into the pretreatment plant. The blowing air is extracted from the blowing tunnel via a return air duct with adjustable suction apertures.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Force-of-gravity separators, which are used as pre-filters or for the separation of large quantities of dust and swarf. Cyclone separator Cyclones are force-of-gravity separators. The separation principle is based on centrifugal force, which is produced by the tangential injection of the raw air. Cyclones are used as pre-filters or for the separation of large quantities of dust and swarf. The degree of separation of a cyclone is not normally sufficient to meet the usual environmental protection requirements. The cyclone exhaust air must be post-filtered in most cases. Product description A cyclone essentially consists of three parts: the intake cylinder, the cone and the immersion tube. In the intake cylinder, the raw air is brought into a circular path by means of tangential injection. Due to the taper of the subsequent cone, the speed of rotation increases sharply, so that the particles are pressed by centrifugal force against the outer wall and decelerated by friction, causing them to drop out of the air stream and fall down. The cleaned air leaves the cone in an upward direction via the central immersion tube. Cyclones are usually welded sheet steel structures. Cellular wheel sluices or, in individual cases, double-gate sluices are used for the pressureless discharge of the material. In order to increase the cyclone effect, or the degree of separation, counter-spirals with a pipe connection can be placed on top of the immersion tube. Further options are, for example, wearing devices, explosion pressure relief devices, control flaps, level monitoring devices and manufacturing in stainless steel or galvanised sheet steel.

Request for a quote

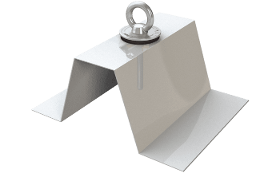

ABS SAFETY GMBH

Germany

You can use this stainless steel anchor on trapezoidal sheeting (positive or negative) either as an anchorage point or for attaching a safety net. The special toggle bolt included in the package comes with its own integrated seal. EN 795:2012, A + EN 1263-2:2014 Sandwich and trapezoidal sheeting (positive/ negative) Steel ≥ 0.75 mm Aluminium ≥ 2.00 mm

Request for a quote

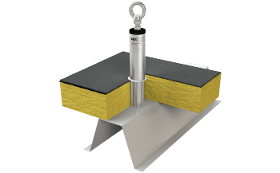

ABS SAFETY GMBH

Germany

Install this kind-to-you-roof, stainless steel anchorage point on trapezoidal sheeting using just one single toggle bolt (included). After installation, the supporting rod (Ø 42 mm) fits the opening made in the insulation layer perfectly. EN 795:2012, A + CEN/TS 16415:2017 Trapezoidal sheeting ≤ 0.75 mm Ideal for retrospective installation Installation materials included

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The Welbee P502L is the top model for perfect welding of steel, stainless steel and aluminum. It combines all the new features and functions of the M400 / 500, M400L and P402, making it the perfect choice for all applications. • High-speed welding on thin stainless steel sheets • Unique appearance of the seams due to OTC aluminum welding characteristics • High speed pulse mode • Increased gap-bridging ability • Low spatter: maximum spatter reduction for the entire current range, spatter reduction up to 80%

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The premium installation system consists of high-grade NiroSan®-Industry press fittings with a red moulded sealing ring made from FKM (fluoro and perfluoro elastomers) for temperatures of up to 200 °C and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® Industry press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Industry press system and its components are certified in accordance with the rules and regulations of all important British and Continental certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The premium installation system consists of high-grade NiroSan®-Industry press fittings with a red moulded sealing ring made from FKM (fluoro and perfluoro elastomers) for temperatures of up to 200 °C and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® Industry press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Industry press system and its components are certified in accordance with the rules and regulations of all important British and Continental certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The innovative SANHA installation system NiroTherm® combines high-quality NiroTherm® press fittings with a black sealing ring made from EPDM (=ethylene propylene diem rubber) and NiroTherm® stainless steel system tubes. The system is produced from the material 1.4301 (AISI 304). Due to the well-known corrosion resistance of stainless steel, NiroTherm® offers installers therefore a real alternative compared to conventional steels when it comes to closed systems in humid atmospheres such as screed. Since it needs considerably less isolation against humidity*, the installation is faster and labour costs accordingly lower. In addition to the system description, NiroTherm® system press fittings are marked on the outside with a red dot. * This does not affect thermal insulation necessitated by national energy efficiency laws.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quoteResults for

Stainless steel sheets - Import exportNumber of results

33 ProductsCompany type