- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sprays

Results for

Sprays - Import export

MSO MESSTECHNIK UND ORTUNG GMBH

Germany

System for spray quality monitoring a multitude of spray nozzles e.g. for agricultural sprayers

Request for a quote

DURSOL-FABRIK OTTO DURST GMBH & CO. KG

Germany

AUTOSOL® KONTROLLSPRAY For quick and easy control of the polished surface. Oil and wax components from grinding pastes and polishes are safely removed in order to optimally evaluate the polishing result. Silicone-free.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

They are the pipe made by stainless steel 304,mainly use for the connector.

Request for a quote

MSO MESSTECHNIK UND ORTUNG GMBH

Germany

Radar Sensor measuring Spray quality signature for industrial applications

Request for a quote

GSW SCHWABE AG

Germany

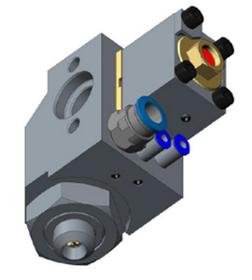

A fitting extension Actuators, manifolds, connectors of all kinds this GSWprogram is as individual as the spray applications. Take a look at the following chart or call our specialists right away.

Request for a quote

GSW SCHWABE AG

Germany

all nozzles are equipped with locking valve to prevent dripping after shutoff all nozzles come with fitting for the PressSpray hose P940

Request for a quote

GSW SCHWABE AG

Germany

Electropneumatic initiation to stay within the press cycle. Fineadjustment of individual nozzles allows precise lubrication right at the die – for an increase in dielife and productivity. No spray mist as only the pump is airpressurized.

Request for a quote

GSW SCHWABE AG

Germany

Turn off all nozzles you don´t need and apply lubricant only where actually needed to gain longer dielife and more productivity. At the same time, don´t lose sight the pump is airpressurized not the nozzle thus no spray mist.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA release spray (art. no. 9515000) is used to release patterns and moulds. After the solvent has evaporated, a strong release film is formed. ALWA release spray may not be polished.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Compact and highly flexible. The spray valves as a compact combination of our nozzles with different spray patterns and the unrivalled valves of the JB series. The spray valves are perfectly suited for use with stationary nozzles such as forging rollers, cross wedge rollers or presses.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Due to the variety of solutions we can supply you with a wide range of spray heads made to measure. Whether plate spray head, single nozzle spray head or a combination. With our know-how we develop your spray head that fits your requirements exactly.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

The modular manual spray lances were developed for simple spraying requirements in the forging and die-casting industry. Compact design, easy to handle and with the 2-step trigger ideal for spraying and dry blowing The large selection of spray lances and nozzles allows an optimal adjustment of the spray mist for your requirements. Due to the robust design of our manual spray lances, continuous operation over years is no problem.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Mobile, compact and multifunctional. Whether as manual spraying equipment or on a fully automatic spraying system, the compact supply tank with its 45 litre stainless steel tank is suitable for all tasks. Equipped as standard with a pneumatic lifting device, handling is particularly easy. By using proven components, the sprayer is perfectly suited for long-term use. The device is suitable for spraying lubricants or coatings with a high solid content. To change the container or clean it, the complete container cover with all attachments is lifted pneumatically.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Mobile, compact and multifunctional. Whether as manual spraying equipment or as compact solution for experiments. The compact pressure vessels with up to 18 litres useful volume are suitable for all tasks. The particularly easy handling makes these containers a popular entry-level solution. By using proven components, the spray unit is perfectly suited for long-term use. The pressure tanks with a self-developed circulation system are also suitable for spraying lubricants or coatings with solid content. For particularly easy transport, all pressure vessels can be equipped with a chassis.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Mobile, compact and multifunctional. Whether as manual spraying equipment or as compact solution for experiments. The compact pressure vessels with up to 18 litres useful volume are suitable for all tasks. The particularly easy handling makes these containers a popular entry-level solution. By using proven components, the spray unit is perfectly suited for long-term use. The pressure tanks are suitable for spraying all commercially available lubricants without solid content.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

The revolution in spraying technology! The patent registered single nozzle spray head combines the best of both worlds. Robust, simple and highly flexible in application. Each nozzle spray head can be controlled individually or in groups. Every possible contour can be sprayed - without set-up times. How does it work? The nozzle plate is made by simple stainless steel parts. The nozzles are then individually fixed on a matrix - that' s it! The control can be done in groups or individually - at any time! Every single spray jet can be individually changed by exchangeable nozzle heads. What is the cost? Thanks to the use of the most modern materials and additive manufacturing processes, the nozzles cost only a very low percentage compared to conventionally machined nozzles.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Unique plate spray heads adapted exactly to your requirements and geometries. Thanks to a design developed by Jerko, the spray heads produce a uniform and powerful spray pattern with ideal atomisation and high impact speed. Optimal cooling of the tools in the shortest time! Our plate spray heads enable the fastest spraying times of all spraying systems available on the market! Jerko plate spray systems are also characterised by a robust and simple construction. Blockages, costly repairs or the adjustment of calottes are a thing of the past. The modular design allows for a wide variety of geometries by simply changing the spray or carrier plates. Expensive special spray heads, nozzle attachments or obsolete calotte spray heads are no longer necessary

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAMAT GMBH & CO. KG

Germany

High-pressure cleaning and surface preparation with water requires precise management of the water jet. This precise management is necessary to ensure that the required result (e.g. surface finish) is achieved within a reasonable time. The method must be safe and fatigue free. With this in mind, we offer a specially designed and manufactured range of high pressure guns with electrical or mechanical control. The exceptional ergonomics of these tools have been achieved through innovative detail solutions: For example, our high-pressure guns are equipped with a special swivel handle that transmits any torque to the wrist. In addition, the hose connection can be swivelled in all directions, allowing optimum hose routing for all working situations. Our range of high pressure guns is complemented by various versions of foot valves, rotating gun lances, rotating nozzles and other accessories for a wide variety of applications, such as pipe cleaning.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Venjakob has combined – for the first time in the industry – a robot with a surface spray painting machine. VEN SPRAY VARIO offers the flexibility of an industrial spray coating robot and the high output of an automatic surface spray coating machine. The outer edges of the parts are precisely coated by the robot, and the surfaces are sprayed "inline" at a constant throughfeed speed without any stopping or stop and go by the spray guns of the downstream linear axis. In comparison to the usual Cartesian robot systems on the market, this leads to an approx. 50 % higher lacquering performance(surface|minute). In addition, the new system technology optimises the surface quality, as it leads to visibly better results by linking the paint film at transitions from surfaces to outer edges. Another decisive system advantage of the VEN SPRAY VARIO is the ongoing guarantee of reproducible production qualities. The perfect finish of 3D workpieces is particularly impressive. For coating complex 3D parts as a stationary batch we recommend using the optionally available paper belt transport system. In addition to the described flexibility, the plant technology can also be used for surface coating only. As an alternative to a manual spraying station a single robot can be used for complex geometries. The technically sophisticated paint recovery system achieves maximum efficiency. The recyclability of the recovered overspray and the considerably reduced use of cleaning agents provide an impressive energy balance. In addition, the efficient ventilation technology noticeably reduces the resulting energy costs. The modular design ensures a safe investment in the long term. The integration of additional robots and other adjustments to meet the continuously growing demands on our customers' production processes are possible at any time.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This "stand-alone solution" is designed to meet flexible production requirements and can be used for solvent and water based paints. This spray coating machine is both economical and environmentally friendly. It can optionally be equipped with a belt cleaning system and/or a paper transport belt.This makes it possible to alternate between both modes of operation. A quick change between two paint systems (water/solvent based) is simple and fast. This makes it especially attractive for smaller companies to replace manual painting. Working width: 1,300 mm, Working height: 920-960 mm, Machine dimension: 1,900 mm (length) Feed speed: 2-4 m /min. Exhaust air volume: 7,000 m³/h, Supply voltage: 9.6 kW/ 12 A,

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Large surface area coating can more cost effectively be accomplished using fewer, moving spray guns. Optimize your coating efficiencies with the flexible automation delivered by Venjakob Reciprocators. Nutro, our factory in the USA is the leader in gun drive technology. Large surface area coating can be cost effectively accomplished using fewer, moving spray guns. Products include short-stroke machines equipped with a crank arm type mechanical design (oscillators), most common in powder coating applications. These designs are impractical for long stroke machines (reciprocators) which have used a variety of drive systems including chain driven units, and other electronic systems. Nutro machines are respected for their robust design, high payload capacity and reliability. Since these spray gun drives often support a high payload of guns, hoses and accessories, a heavy duty design is desirable since these machines are often loaded beyond their rated capacity. Nutro’s machines are also cost-efficient and the simplicity of design makes them easy to service. While Nutro has frequently sold spray gun drives to end customers, more commonly Nutro spray gun drives are resold by other OEM manufacturers under a private label arrangement such as Nordson Corporation. Nutro has worked closely with these OEMs to design machines according to their budgets, specifications and preferences. The scope of delivery includes both standard spray gun drives which can be used in series machine lines as well as customer specific machines as required.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Depending on the workpiece geometry and size, we offer various coating solutions by means of a chain-on-edge system and a round indexing table. To meet individual requirements, either a vertical or a horizontal chain-on-edge system can be used. Spray painting machines for rotating workpieces are distinguished by their high functionality on a smallest possible footprint. In addition, they can be controlled in a circulating or cycled mode, and combined with various conveyor systems and drying methods.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This machine has a twin cleaning unit, therefore it can be used for a dual application of water and solvent based paint systems. Reproducible results guarantee process reliability. The modular construction enables future expansion of the machine line and thereby ensures your investment for the future. Working width: 1,300 mm Working height: 920-960 mm Feeding speed: 3-8 m/min. Exhaust air volume: 7,000 - 10,000 m³/h Connect value: 20 KW Machine dimensions: 5,100 x 3,440 x 2,850 mm (L/M/H) The twin cleaning units of this flexible system technology enable a dual application for water and solvent based paint systems. The targeted paint-recovery by means of the patented V-belt system offers a maximum of profitability and environmental friendliness.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Your production spectrum requires both machine technologies? Utilisation, however, is insufficient for a profitable operation of both systems? In this case, make your decision in favour of our new VEN SPRAY CONTOUR! - A 2 in 1 solution. NEW: Belt cleaning system + cleaner and/or combined configuration with a paper belt conveyor system: the paper belt system can be employed for the use of fast drying, non-recoverable paint/lacquer systems (e.g. polyester and 2 C paints/lacquers), whereas the belt system is suitable for recoverable paint/lacquer systems As an option, a selection can be made between dry or wet cleaning. An energy saving recirculating air operation is also possible with solvent based paints (0-50%).

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The large volume booth used here enables an increase in the flexibility and, at the same time, a higher production and quality assurance than that used in the VEN SPRAY MIN concept. Integrated fast colour change systems for one and two component lacquer systems as well as the feasibility of a wet in wet application of two lacquer systems (depending on the paint systems) in one pass, establish faster production times, reduced rejects as well as a resource saving utilization of the spray media. Example of a complete finishing line including pre-treatment and drying:

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The VEN SPRAY MINI is a cost-effective entry model. Depending upon requirements, stand-alone solutions with separate pre-treatment and drying technology as well as complete through-feed concepts are available. Perfect lacquering of 2 D- 2.5 D workpieces. The modular concept permits adaptation to changing production requirements at any point in time by retrofitting new modules, thereby making your investment future-proof. Tell us your requirements, we develop the suitable concept!

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

To conform to market requirements, widely differing machines for painting/coating mouldings, window parts and other profile components were developed. The type and number of guns depends both on the paint system and on the quality envisaged. Air, Airmix or Airless spraying systems can be used for this purpose. The individual machine types can be configured with all conveyor systems of our portfolio and combined with the respective drying systems. The difference between the VEN SPRAY MOULD (LT) and (LW) variants is their type of extraction. LT stands for dry extraction, LW for water-backed extraction. VEN SPRAY MOULD COOLAC is exclusively designed for processing water-based paints. The overspray is constantly collected and condensed in chilled collector systems. The condensation of the controlled air humidity keeps the collector devices and chilled conveyor systems permanently wet. This reliably prevents paint particles from drying during operation. The strip painting plants can be supplemented by further Venjakob plant technologies specifically tailored to the process such as brush sanding/denibbing machines, dryers or conveying equipment.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The design of the automatic 7 axis coating machine meets today's market requirements. As such, it can be employed for small and large order batch sizes, it paints the workpiece front and rear faces as well as 3D part geometries without problems. Transport unit for stacking trays/work piece carriers, consisting of:

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

With its VEN SPRAY PERFECT Venjakob has the innovative answer to all requirements encountered on the market. Based on decades of know-how in the realisation of high-performance spray painting plants, it is the flexibility of this new generation that convinces. In the long term, the modular system takes into account all production requirements. At the time of machine purchase, its concept realises all variants, from "one off batch size" through to large series production in the high-end range. The modular concept permits implementation of changing framework conditions at any point in time by retrofitting new modules, thereby making your investment future-proof. Working width: 1,300 / 1,600 / 2,200 mm Working height: 940 mm Feed speed: 3-8 m/min Exhaust air volume: 7,000 - 10,000 m³/h Connection value: 20 KW Machine dimensions: 2,280 / 2,800 mm (length of booth) The sophisticated spray gun control minimizes the rate of overspray. With the patented V-belt design up to 98 % of the liquid overspray can be reclaimed. The paint retrieved in this way is recycled into the paint process. Over and above, the innovative ventilation system improves the ecological energy balance. The short setup times, long service life of the filter elements, fast changing times for spray systems and automated paint-change procedures offer a very high degree of efficiency. The twin cleaning units allow the use of solvent-based paints as primer and the direct switchover in split seconds to the second cleaner operating with water-based paints. Maintenance and cleaning operations take place completely separate from the production process.

Request for a quoteResults for

Sprays - Import exportNumber of results

32 ProductsCompany type