- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sealing ring

Results for

Sealing ring - Import export

IGUS® GMBH

Germany

iglidur® sealing lip bearing d1 [mm]: Quick and easy-to-mount polymer bushing made of iglidur® J (JDSM) or iglidur® V400 (VDSM) with clip-on radial shaft seal ring as sealing for the rotating shaft. Seals off against dirt, dust as well as all pressure-less media. Polymer bushing with clip-on radial shaft seal ring Sealing for rotating shaft Temperature application range like iglidur® J Coefficient of friction only 10% higher than in iglidur® J Coefficients of friction identically exceptional like iglidur® J Reduced installation space as well as easy and simple mounting Realizable with numerous sealing types High-temperature option VDSM possible Temperatures till 150° C Material: iglidur® J High temperature option VATM, iglidur® V400 Seal ring made of fluorelastomer Bearing-sealing combinations for other applications on request When to use it? When the penetration of dirt and spray water should be prevented When only a small installation space is available in the axial direction When an existing seal should be integrated in a plain bearing When not to use it? When pressurized media should be sealed When absolute impermeability to the shaft and housing is needed continuously We'll gladly do the developing with you iglidur® sealing lip bearing d1 [mm]:

Request for a quote

CINCHSEAL EUROPE GMBH

Germany

Corrugated ring seals with soft material overlays, mostly made of graphite or PTFE, exhibit very high tightness combined with minimum creep (loss of bolt force). This combination of outstanding properties makes corrugated ring seals ideal for refineries, chemical and petrochemical plants. ✔ Characteristic values according to EN 13555 ✔ TA Luft according to VDI 2440 ✔ Fire Safe according to ISO 10497 / API 607 ✔ Blowout test according to VDI 2200 ✔ BAM for oxygen applications

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

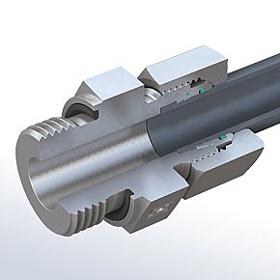

Soft-Sealing Cutting Rings provide an additional safety and protection against potential leakage risks, e.g. caused by the settling of purely metallic sealed connections, temperature fluctuations or considerable pressure and vibration loads in the system. "Sweating effects" on the connection points can be permanently avoided. The type FI-WDDS Soft-Sealing Cutting Ring of the STAUFF Connect range is characterised by the elastomer sealing, which is located in a specially designed groove close to the rear end of the 24° taper and protected to prevent loss. An additional o-ring is used to secure the secure the second potential leakage path between the cutting ring and the tube – even in the event of unfavourable tolerances FKM/FPM (Viton®) is used as the standard sealing material and enables problem-free use of the system for challenging applications involving high temperatures or aggressive media. Like all other components in the STAUFF Connect product range, the cutting ring...

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

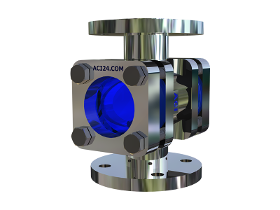

Vacuum flow sight glass type N880V with O-ring seal for vacuum applications

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Robust case with wall thickness of 5 mm either in seawater resistant aluminum or in stainless steel - shaft in stainless steel - rotating components with permanent magnet in front chamber - electronic circuit with ASiC and Hall elements and interface components fitted within main chamber, separated from rotating components by a metallic wall - integrated absolute multiturn gearbox for the acquisition of revolutions - optional potting against water jets (IP 69K) - electrical connections via round plug M12x1 or lead exit.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Robust case with wall thickness of 5 mm either in seawater resistant aluminum or in stainless steel - shaft in stainless steel - rotating components with permanent magnet in front chamber - electronic circuit with ASiC and Hall elements and interface components fitted within main chamber, separated from rotating components by a metallic wall - integrated absolute multiturn gearbox for the acquisition of revolutions - optional potting against water jets (IP 69K) - electrical connections via round plug M12x1 or lead exit.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Recording of the angular position and revolutions by mens of Hall sensors - multiturn version with absolute transmission for up to 4096 revolutions - data output plus parameterisation and diagnosis via Profibus-DP. Robust housing manufactured from seawater-proof aluminium or stainless steel - stainless steel shaft - ball bearing with radial shaft seal - sensor circuit consisting of ASIC with Hall elements - electrical connections via the connecting cap with threaded cable connections. The absolute encoders are designed for direct connection to the PROFIBUS-DP. The interface is implemented with the SPC3 Siemens PROFIBUS controller. The protocol corresponds to DP-Slave Class 2 functionality in accordance with Profibus profile for encoders, No. 3.062, and is described in detail in the TRD 12770 user manual. The TRD is mechanicallly and electrically compatible with the electro-optical encoder CRD.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Recording of the angular position and revolutions by means of Hall sensors - data output plus parameterisation and diagnosis via PROFINET. Robust housing manufactured from seawater-resistant aluminium or stainless steel - stainless steel shaft - ball bearing with radial shaft seal-sensor circuit consisting of ASIC with Hall elements - electrical connection via M12 connector or cable outlet. The Profinet interface according to IEC 61158 / 61784 or PNO specifications order No. 2.712 and 2.722, version 2.2, is integrated into the model series TRT absolute encoders. Real time classes 1 and 3 are supported, i.e. Real Time (RT) and Isochronous Real Time (IRT) plus the requirements of conformance class C. To achieve the SIL2 level, the TRT/S3 contains addtitional internal monitoring mechanisms as well as safe communication via PROFIsafe. The PROFIsafe protocol is implemented according to the PROFIisafe Profile for Safety Technologie version 2.4 (PNO Order No. 3.192)

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The incremental encoder with the model designation FOI records the angular position by means of a magnetic sensor and signal processing and generates the corresponding pulse outputs. The robust steel housing with anti-corrosion coating and stainless steel flange (AIMgSi1) ensures versatile use of the incremental encoder for your individual application. The shaft of the FOI is made of stainless steel and the bearings are equipped with a shaft sealing ring.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Robust housing (wall thickness 5 mm) made of seawater resistant aluminium (AlMgSi1) or stainless steel (material: 1.4305 optional 1.4404) - Redundant power supply as well as sensors and electronics - Common shaft (measuring axis) with ball bearing, shaft sealing ring and permanent magnets in prechamber - Sensor circuit consisting of ASICs with Hall elements and interface electronics in closed main chamber - The contactless electromagnetic sensor systems are extended by a 12-bit D/A converter so that the measured variable is available as an analog signal from 0 (4) to 20 mA or 0 to 10 VDC - Electrical connections via connector M12x1.

Request for a quote

Z.I.S. KUNSTSTOFF GMBH

Germany

Cable conduits made of PE-HD with plug-in sleeve Manufactured acc. to DIN 16876 Standard design: Sleeve type: integrally moulded plug-in sleeve (SM) Sealing ring: compression lip sealing ring, type “SX” (inserted in the factory) Sharp end: with plug-in depth marking and chamfer Length: 6 m Colour: black Inner surface: smooth Possible designs: Quality: DIN 16874 Length: 1 m to 6 m Coloured stripes: co-extruded Colour: on request Outer surface: coloured co-extruded or solid dyed Inner surface: inner grooves for reducing the cable pull-in forces Labelling: acc. to customer specifications

Request for a quote

Z.I.S. KUNSTSTOFF GMBH

Germany

Cable conduits made of PVC-U with plug-in sleeve Manufactured acc. to DIN 16875 Standard design: Sleeve type: plug-in sleeve Sealing ring: inserted in the factory Sharp end: with plug-in depth marking and chamfer Length: 6 m Colour: black/anthracite Possible designs: Länge: 1 m to 6 m Farbe: special colours are available on request Labelling: acc. to customer specifications

Request for a quote

Z.I.S. KUNSTSTOFF GMBH

Germany

Cable conduits made of PP with plug-in sleeve Manufactured acc. to DIN 16878 or prEN 14285 Standard design: Sleeve type: integrally moulded plug-in sleeve (SM) Sealing ring: compression lip sealing ring, type “SX” (inserted in the factory) Sharp end: with plug-in depth marking and chamfer Length: 6 m Colour: black Inner surface: smooth Possible designs: Length: 1 m to 6 m Coloured stripes: co-extruded Colour: on request Outer surface: coloured co-extruded or solid dyed Inner surface: inner grooves for reducing the cable pull-in forces Labelling: acc. to customer specifications

Request for a quote

SANHA GMBH & CO. KG

Germany

The SANHA®-Therm Industry installation system consists of tried and trusted SANHA®-Therm Industry system press fittings with a red moulded FKM (fluoro and perfluoro elastomer) sealing ring for high temperature applications and SANHA®-Therm carbon steel system pipes.

Request for a quote

SANHA GMBH & CO. KG

Germany

System press fittings from copper and copper alloys for copper pipes according to EN 1057 for solar and high-temperature applications for compressed air. SANHA®-Press Solar system fittings have red moulded sealing rings made from FKM.

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-quality NiroSan® SF press fittings with red moulded sealing rings made of FKM and NiroSan® stainless steel system pipes according to EN 10312. Specially made for all applications that require silicone free components. Silicone-free moulded sealing rings are ideally suited to applications such as varnishing and painting industries. All NiroSan® SF press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. Certified in accordance with all relevant national and European certification bodies.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SANHA GMBH & CO. KG

Germany

The exclusive MASTER 3 sound-insulating drain system from SANHA consists of high-quality three-layer pipes and modern fittings. The drain pipes are constructed with three perfectly matched layers that work together to meet all the demands that a drain system is subjected to in the construction of a modern house, apartment and industrial building. Each layer optimises the properties of the pipe: The smooth inner layer prevents encrustations and is partly responsible for the good sound insulation properties. The solid middle layer is extremely robust and the brown outer layer provides excellent impact resistance even at low temperatures. The sealing ring consists of styrene-butadiene rubber (SBR).

Request for a quote

SANHA GMBH & CO. KG

Germany

System press fittings from copper and copper alloys for copper pipes according to EN 1057 for flammable gases and interior gas piping with yellow sealing rings made from HNBR (hydrated nitrile butadiene rubber). SANHA®-Press Gas system fittings are tested according to BS EN 8537 and certified or approved by all relevant national and international certification bodies. Our system fittings are labelled with a yellow „PN 5 - GT/PN 1“ on the outside.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroTherm® Industry press fittings with a red sealing ring made from FKM (Fluoro carbon) and NiroTherm® stainless steel system pipes. The system is made from the material number 1.4301 (AISI 304). NiroTherm® Industry offers installers therefore an attractive alternative to commonly used materials for closed systems that needs considerably less insulation work against corrosion. NiroTherm® Industry system press fittings are marked on the outside with a read "HT" and a red dot.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The innovative SANHA installation system NiroTherm® combines high-quality NiroTherm® press fittings with a black sealing ring made from EPDM (=ethylene propylene diem rubber) and NiroTherm® stainless steel system tubes. The system is produced from the material 1.4301 (AISI 304). Due to the well-known corrosion resistance of stainless steel, NiroTherm® offers installers therefore a real alternative compared to conventional steels when it comes to closed systems in humid atmospheres such as screed. Since it needs considerably less isolation against humidity*, the installation is faster and labour costs accordingly lower. In addition to the system description, NiroTherm® system press fittings are marked on the outside with a red dot. * This does not affect thermal insulation necessitated by national energy efficiency laws.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies.

Request for a quoteResults for

Sealing ring - Import exportNumber of results

48 ProductsCompany type