- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rollers

Results for

Rollers - Import export

BORNEMANN GMBH

Germany

Roller die Roller die for the roller process of round work pieces with or without starting slope. These dies can be given flexible texts from individual insert milling or wire-cut excavations. The selection of materials depends on the relevant use. During production, we are guided by your drawings or data.

Request for a quote

TORWEGGE GMBH & CO. KG

Germany

The slim design and small size of our versatile roller rails make them the perfect solution for conveying lightweight goods such as cardboard boxes, light picking containing or storage containers.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

CMC TEXPAN's roller separators are very suitable for processing fresh and recycled wood; they oer high performance when processing wet or semi-wet wood materials. Their principle of operation is based on the rotation of a group of rollers provided with a specic prole or disc pattern; they are adequately spaced apart, whereby such spacing denes the particle size selected. The material is bouncing on the rollers to separate the fractions. Particles of a size smaller than the gap between the rollers pass through the roller spacing. Larger particles are conveyed by the rollers and discharged. The size of the desired fractions can be simply adjusted by changing the gaps between the rollers and/or by using rollers with dierent patterns. "SRD" type - for pre-crushed material "SRU" type - for all typical applications and numbers of fractions "SRO" type - for wet or dry strands

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Similar in design to yoke type track rollers with axial guidance, our KIS cam rollers are based on needle roller or cylindrical roller bearings. Instead of an inner ring, they are equipped with a solid bolt. This serves as an inner ring replacement and is provided with a fastening thread. They are ideal for applications that require high rigidity, load carrying capacity and guiding accuracy. Our stud type track rollers are used, for example, in conveyor technology, machine tools and medical technology. Depending on the application requirements, the KIS range offers a wide variety of designs. We are happy to advise you on the right solution for your application!

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

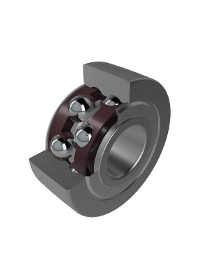

Our KIS track rollers are available as self-retaining, single or double row ball bearings with particularly strong outer rings. In addition to high radial forces, they also absorb axial forces in both directions. Track rollers are characterised by their robust construction featuring particularly thick-walled outer rings with a crowned outer surface (alternatively with a cylindrical outer surface or outer profile). They are designed to carry high radial loads and also tolerate axial loads that can arise due to minor misalignments, skewing or short-term start-up shocks. The assembly is constructed with a fixed inner ring mounted on axles. In this case, the track rollers are not installed in a housing bore, but are supported on a flat raceway (mating track). To ensure a reliable seal, the track rollers are fitted with a lip seal or cover discs on both sides. This prevents the ingress of dirt, dust and other contaminants while maintaining lubrication inside the bearing.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

The roller deck is used to transport ULDs and pallets in a single direction on a horizontal plane and is combined with other elements to create an overall system. Flow plane: Horizontal Flow direction: Unidirectional Functions: Buffering and transporting ULDs Operating modes: Manual and powered Feature: Non-slip walkways between the rollers

Request for a quote

ROLLON GMBH

Germany

Sturdy and practical linear rails with radial ball bearing sliders. The X-Rail is a family of linear guides with radial ball bearing sliders for applications requiring cost efficiency and high resistance to corrosion. The linear guides with shaped raceways and the linear guides with flat raceways are available in stainless steel or galvanised or nitrided metal sheeting. With the T + U configuration, the X-Rail system can compensate for any axial misalignment in parallelism of the mounting surfaces.

Request for a quote

BORNEMANN GMBH

Germany

Brass rollers or brass stamping wheels are engraved as raised or recessed. The engraving is circumferential on the wheel or roller and can be given the corresponding engraving in accordance with your needs. Leather belts, textile and decoration bands, amongst other things, are stamped and printed.

Request for a quote

BORNEMANN GMBH

Germany

Steel rollers or embossing rollers are used in the most varied or areas to transfer surfaces to various materials and to thereby give the product a high-quality character. The rollers are used to stamp aluminium film, paper, cardboard, leather and other materials.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Due to the ever-increasing level of automation, coated rolls and rollers are now used in almost all production facilities. These rollers and rolls are used in a wide variety of applications (transport, finishing, cleaning, coating, drying, etc.). What is particularly important is the quality of the coating, which determines the service life of the roller and the processing process.We manufacture completely coated rollers, i.e. We provide you with the roller core made of aluminum, steel, etc. and the desired coatings (rubber, Vulkollan®, etc.) from a single source. We can also roughly pre-grind your rollers, finely grind them or even provide them with grooves.As a cost-effective alternative, we also offer you to have your rollers recoated by us. Here too we can choose between different coatings (rubber, Vulkollan®, etc.). According to the customer’s wishes, we can also pre-grind, finely grind or provide these rollers with grooves. We would be pleased to advise you!

Request for a quote

GSW SCHWABE AG

Germany

To serve coil stock thicknesses of up to 15 mm Large diameter entry pinch rollers for smooth and lowwear strip transport Synchronized drive of all bottom work rollers and both entry pinch rollers Rollers are kept perfectly parallel with their penetration shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Enormous potential for performance and straightening quality through absolutely warpresistant head construction; supported by optional backup rollers and allroll drive system Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening as "cleaning stroke" Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Jobmemory for mot. straightening roller adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

GSW SCHWABE AG

Germany

High feeding accuracy, quick cycles and simple operation Servo feeding in compact design with maintenancefree AC servo motor Fits just about any press +/ 0,025 mm feeding accuracy through incremental servo encoder Lightweight rollers with special hard chrome layer Mechanical pilot release Sturdy steel plate bolton design Height adjustment via threaded spindle Catenary rolls and edge guides at machine entrance Stock guides at exit Highperformance control with good functionality; with remote control for setup on 3,5 m cablel 24 V DC proximity switch adjustable piloting lever to be mounted to press pneumatic pilot release

Request for a quote

GSW SCHWABE AG

Germany

No coil expansion needed Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 21 individually adjustable straightening rollers to serve any almost demand on the quality of the straightening result Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers Clockspring guard Allroll drive for straightening rollers Hydraulic hold down arm (optional w powered endwheel) Hydraulic threading system with snubber and peeler (optional w powered snubber wheel) Motorized coil guides Motorized straightening rollers Hydraulic opening / closing of straightening head Hard chromed rollers Edge guides adjustable to center via handwheel (optional motorized) Jobmemory feature for all motorized functions... etc

Request for a quote

GSW SCHWABE AG

Germany

Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 13 individually adjustable straightening rollers to serve almost any demand on the quality of the straightening result Clockspring guard Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers

Request for a quote

GSW SCHWABE AG

Germany

Good old technology for wellknown processes Roller Lubricators are popular despite minimizer spray solutions. GSW supports you with a preselected range of products and we help with practical advice based on our experience. On top of that, we offer a “highend” solution with our hybrid Lubricators that feature a combination of external spray and roller lubrication.

Request for a quote

GSW SCHWABE AG

Germany

This line of Roller Lubricators will balance strip floating thanks to a springsocketed inner box. Stainless steel housing, flexible pass line and special, individually controllable spray nozzles benefit setup time and operating costs.

Request for a quote

SPANSET SECUTEX GMBH

Germany

With securoll secutex offers a specially developed coating for cylinders and rolls, which is cast in form or applied directly onto the roller core. During product development the vast experience of secutex with all types of coatings was introduced. secutex supplies a wide selection of securoll for almost any application. Material hardnesses of 55°90° Shore are supplied. The innovative process ensures high precision in the coating with very low tolerances as well as optimum and longterm bonding between the cylinder/roller core and the securoll material. This ensures that the securollcoated cylinders and rollers have a a high degree of mechanical strength and wear resistance. What does securoll offer? High abrasion resistance Different Shore hardnesses Temperature resistance Low tolerances Different surfaces Special forms Coated cylinder and rollers Noisereducing Protects materials Long service life Resistant to hydrolysis

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GSW SCHWABE AG

Germany

With threephase servo drive sized according to job requirements Machine body in sturdy clean steel plate design Rollers made of highquality 63 RW tool steel, hardened and polished Pneumatic pilot release with parallel lift of upper roller, guided on gear rack Entry catenary rolls Manual edge guides Simple programming of even complex feeding cycles, Display in cleartext Manual functions for setup such as creep speed, jog mode, single feedtolength Simple memory and recall of job programs for quick changeover Mounting bracket with height adjustment via spindle or hydraulic handpump (optional motorized) Hard chromed or polyurethane coated rollers (optional with Topochrome coating for highgrip feeding) Measuring wheel system for highest feeding accuracy Stroke limitation for faster piloting Fine adjustment of upper roller and strip guiding device for thin stocks (starting at 0,1 mm thickness) Central edgeguides with hand wheel

Request for a quote

GSW SCHWABE AG

Germany

Both straightening and (servo) feeding performed in one operation Saves floor space as 2nd loop between standalone straightener and servo feed is eliminated Large entry pinch rollers driven synchronously with all bottom work rollers Great feeding accuracy of +/ 0,1 mm Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Operator interface provides simple insertion or recall of feeding paramenters or memorized programs Hard chromed rollers Polyurethane coated rollers Hydraulic cleaning stroke Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Motorized central height adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

GSW SCHWABE AG

Germany

Both straightening and (servo) feeding performed in one operation Saves floor space as 2nd loop between standalone straightener and servo feed is eliminated Great feeding accuracy of +/ 0,1 mm Operator interface provides simple insertion or recall of feeding paramenters or memorized programs Synchronized drive of all bottom work rollers and both feed rollers Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening Hydraulic full piloting Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Motorized central height adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable for highstrength steel applications Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

GSW SCHWABE AG

Germany

Most simple threading Short setup as roller adjustment can be maintained with coilchanges Most comfortable maintenance and cleaning Synchronized drive of all bottom work rollers and both pinch rollers Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Jobmemory for mot. straightening roller adjustment Central edge guide adjustment via handwheel All roll drive Movable base Manual or hydraulic loop bridge... etc.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Wood-Her rollers consist of an aluminum core. Light-colored rubber is used for the coating, in addition to the polyurethane materials that have long been tried and tested in the woodworking industry, and mainly the elastomer Vulkollan®. The core mounting holes have two side holes.As a service, we offer our customers the opportunity to have their used pressure and feed rollers re-upholstered by us. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design in smooth or grooved form and the most suitable degree of hardness must be determined by the customer. Weinig rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core mounting holes are designed as a keyway or with three side holes.The Weinig rollers are mainly coated with the elastomer Vulkollan® patented by Bayer. We would be happy to advise you by telephone or at your location regarding high-quality and cost-effective design of pressure and feed rollers.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

With the newly developed FAPI-SWITCH series, we have succeeded in designing deflection pulleys in a lightweight system design with an unprecedented smoothness and smoothness of running that set new standards in the belt grinding process. Due to the flexibility, also with regard to different dimensions, belt elephant machines of all brands can be equipped with these deflection rollers. We would be pleased to advise you on which return pulleys can be used in your processing, in order to achieve top process results.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

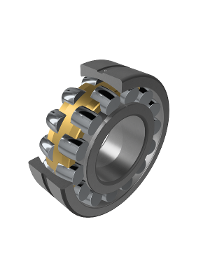

With decades of experience, we manufacture spherical roller bearings at KIS that can support large radial and axial forces in both directions. The perfect solution for applications that have to withstand massive loads. Due to the design of two rows of pendulum-shaped rollers in a common, hollow-ball raceway in the outer ring, our spherical roller bearings can support large radial and also axial forces. This makes them perfect for applications that have to withstand high loads and shocks and compensate for shaft bending or misalignment. In addition to conventional spherical roller bearings (which have no seal and have either a tapered or cylindrical bore), there are also application-specific variants developed for special requirements (e.g. sealed spherical roller bearings or bearings with optimised load ratings). Spherical roller bearings offer high performance and efficiency and are available in a wide range of sizes and designs.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our all-ceramic bearings are characterised by their high corrosion resistance to seawater and various chemicals. They are therefore used, for example, in the chemical industry, in the food and beverage industry, in shipping and in chlorine systems. We can manufacture our full ceramic ball bearings with rings and balls made of zirconium oxide (ZrO2) or silicon nitride (Si3N4), depending on the application. They are available with full balls or with cages made of PEEK or PTFE. The runout accuracies common with precision steel bearings cannot be achieved with all-ceramic bearings, so speed values have to be reduced. Ceramic materials are harder than steel, but also more brittle. Silicon nitride in particular has a low elongation at break and tends to break under tensile stress without prior plastic deformation. We take this into account when selecting the optimum bearing solution for your specific requirements.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

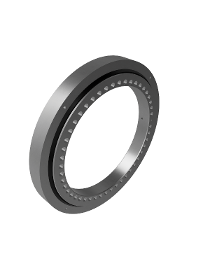

Designed to efficiently support axial and radial forces and tilting moment loads, crossed roller bearings are suitable for applications subject to high loads and speeds. Due to the special crosswise arrangement of the cylindrical rollers in crossed roller bearings, designs with two bearing positions can often be reduced to one. Due to their high rigidity and running accuracy, they offer enormous precision and are used, for example, in robotics, medical technology and lathes. Depending on the application requirements, we at KIS manufacture cross rollers in different configurations. We are happy to advise you on the optimum solution for your application.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our KIS hybrid bearings combine the best of two worlds - the robustness of classic rolling bearings (or stainless steel bearings) and the efficiency of state-of-the-art materials. With an optimised combination of high-quality steel rings and precise ceramic balls, our hybrid bearings offer outstanding strength and durability. Rolling elements made of ceramic offer a current-insulating property. These hybrid bearings have the same dimensions as comparable all-steel bearings and can significantly improve the reliability and robustness of machinery and equipment. In particular, they show their advantages in applications where the bearings are confronted with contamination from abrasive particles, insufficient lubrication, vibrations or current passage. At KIS, we optimise our materials for hybrid bearings to ensure flawless performance in applications under critical conditions at all times.

Request for a quoteResults for

Rollers - Import exportNumber of results

74 ProductsCompany type

Category

- Bearings, roller (15)

- Wheels, castors and rollers (15)

- Metal straightening machines (9)

- Rolling machines (6)

- Conveyor systems (4)

- Wheels, castors and rollers - metal (4)

- Goods handling systems, continuous (4)

- Machine tools, metal shaping - parts and accessories (3)

- Travelators (2)

- Handling - Machines & Equipment (2)