- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- roller conveyor

Results for

Roller conveyor - Import export

TORWEGGE GMBH & CO. KG

Germany

Our solid gravity-driven roller conveyors provide an optimized solution for the internal transportation of your lightweight or heavyweight products. In order to ensure that your conveyed goods flow smoothly and independently all the way from the inlet to the outlet point, the roller conveyor must have the proper declination. This factor must be determined individually according to the type of load carrier and weight of the goods being used for your application. We can also deliver complete solutions that are individually tailored to your requirements; our support already begins during the planning phase for your project. Take advantage of our in-depth experience and benefit from our assessment of your operating conditions and influencing factors (including the suitability of using roller conveyors for your goods) – Leave nothing to chance.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you idler pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Regular rollers prevent belt misalignment and guarantee protection of the belt edges. As the regular rollers only function efficiently when the drum casing is clean, the rollers are equipped and delivered with dirt repellent 60° shore soft rubber. Our regular rollers can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The implementation of impact absorber stations provides effective protection against damage to the conveyor belt in the loading area. The belt is often pierced by sharp, large and bulky goods. Specially manufactured stations supporting impact bars absorb the impact speed. Repair and maintenance costs are thus reduced. In addition, the life expectancy of the conveyor belt and conveyor system is extended as well as the operating conditions significantly improved. Further advantages no jammed rollers causing belt misalignment absorb the drop energy, support the conveyor belt instead of the conveyor rollers in the transport area of the conveyor system and make a reliable running of the belt possible whilst ensuring the least possible friction. infinitely variable alignment to the angle of inclination by means of spindle displacement possible better material sealing due to adjustment of the material guide to within a millimetre

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestFlex Roller is excellent for handling oddshaped boxes, bags and lowgrade cartons in low to medium volume applications. Designed to expand, contract and move easily, the BestFlex Roller is a selftracking, gravity roller conveyor that has a per linear foot capacity of 220Kg per linear metre. The allsteel frame construction provides unmatched structural integrity, whether the conveyor is extended, contracted or configured in simple or compound curves. It is the best choice for moving items without a flat, solid surface. SelfTracking Cartons follow the path of the conveyor without using engineered curves. Adjustable Height Telescopic leg sections are used to raise or lower the conveyor height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability. 40mm Side Plate Aluminium alloy construction features a ribbed design for added strength. Assembled with bolts and locking nuts. Castors with Brakes 127mm x 38mm Swivel Castors allow easy movement.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Flexible powered conveyors provide maximum productivity in shipping, transportation and packaging applications where usability and adaptability are most needed. With its innovative design, the PowerFlex15 powered roller conveyor requires less storage space when fully retracted and can service multiple docking doors for maximum productivity. By powering the conveyor, any package size can be moved, any distance at variable rates of speed. This powered conveyor has a capacity of 150Kg per linear metre. The PowerFlex15 also features an easy and quick way to change out the drive belts giving you added durability and less maintenance downtime. Continuous Duty Multiple Drive Motors Line speed is adjustable from 0 to 36 metres per minute. Start/stop controls at both ends. Self Tracking Cartons follow the twists and turns of the conveyor path without using engineered curves. Adjustable Height Telescopic legs to raise or lower the conveyor bed height.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With its innovative design, the PowerFlex19 powered roller conveyor requires less storage space when fully retracted and can service multiple docking doors for maximum productivity. By powering the conveyor, any package size can be moved, any distance at variable rates of speed. It is an allpower conveyor that has a capacity of 150Kg per linear metre. The PowerFlex19 features an easy and quick way to change out the drive belts giving you added durability and less maintenance downtime. Flexible power conveyors provide maximum productivity in shipping, transportation and packaging applications where usability and adaptability are needed. Continuous Duty Multiple Drive Motors Line speed is adjustable from 0 to 36 metres per minute. Start/stop controls at both ends. Self Tracking Cartons follow the twists and turns of the conveyor path without using engineered curves. Adjustable Height Telescopic legs to raise or lower the conveyor bed height. Square Tubing Legs

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

For different pipes ø: 50-108 mm - Outside ø: 70-150 mm Guide discs made of galvanized sheet steel. Example of appication: Two-piece with clamping screws. For guiding pallets on roller conveyors.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

The truck dock from Lödige facilitates the loading and unloading of air cargo units onto and off trucks. Equipped with a hydraulic lifting unit and a vertical shift function, the truck dock brings conveyor elements into line with the truck loading ramp. ULDs or pallets are transferred horizontally by a powered roller conveyor. Depending on requirements, the conveyor can be replaced or combined with other technologies such as a ball deck or castor deck. A moving version of the truck dock is also available.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

The transfer vehicle is used for transporting cargo horizontally on a single level. The individual loading units are moved on and off the racking by interconnecting the integrated roller conveyor with external roller decks. As well as transporting ULDs which take up the entire surface of the roller deck, it is possible to transfer two containers simultaneously. Flow plane: Horizontal Flow direction: Unidirectional Functions: Transporting, storing and retrieving ULDs Operating modes: Fully automated, semi-automated, maintenance Benefits: A safe way to transport ULDs with care IATA-compliant transportation of ULDs

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Pallet based automated car parking system RESPACE Pallet based technology The pallet based automated car parking system RESPACE is an interesting solution for creating up to 50 parking spaces. Drivers park their car on a pallet in a cabin. The cabin is the only interface between the driver and the car park. From this point everything is automatic. The door of the cabin closes and the car is transported downwards by lift. From there the car standing on the pallet is brought to a free parking space via roller conveyors. The pallet based parking system RESPACE is characterized by a very compact design. From the lift the pallets with the vehicles are moved directly to adjacent parking spaces. Car parking and removal follows according the puzzle principle. The car park has 60 parking spaces and is used as a hotel car parking, but also available to the public.

Request for a quote

WERNER LANGER GMBH & CO. KG

Germany

In the field of storing technology we are pleased to assist our customers with competent advice and our technical expertise / knowledge. We currently produce for example transport rails, component holders but also fully assembled brake rollers for pallet conveyors.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Application Rollers are particularly well suited to the transport of light conveyed material with a smooth and stable underbody. They are used in roller strips, roller tracks, flexible roller conveyors and curved conveyors. They are used in push-through rack storage systems, as deflectors and guide tracks as well as for interlinking different conveyance systems. Load The load-bearing capabilities can be found in the table of dimensions under the “Roller” tab. The conveyance speed of Schulz rollers is up to 2 m per second.

Request for a quote

CRAEMER GMBH

Germany

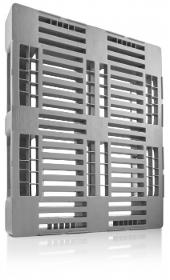

The completely closed TC1 Euro pallet is the benchmark for all closed load carriers, and the ideal heavy-duty pallet for the food, pharmaceutical, and chemical industry. Thanks to its smooth surfaces, the TC1 hygiene pallet boasts excellent cleaning properties, while the cavity-free construction offers reliable protection against contamination or water ingress. Characteristics: Available with 3 runners High load-bearing capacity for heavy-duty applications Patented welding seam geometry of the top and bottom deck as well as solid wall thicknesses ensure highest impact and breakage resistance Dimensionally stable with first-class bending parameters, ideal for roller conveyors and automated high rack warehouses Excellent cleaning properties Chamfered edges on both sides of all runners Options: Corrosion-protected reinforcement profiles, for a load-bearing capacity of up to 1,750kg in high rack Rims: without, 7mm or 22mm RFID transponder

Request for a quote

CRAEMER GMBH

Germany

The completely closed TC3 / TC3-5 industrial pallet is available with 3 or 5 runners. The heavy-duty pallet is the ideal solution for applications in the food, pharmaceutical, and chemical industry – whereever maximum hygiene is essential. Thanks to its smooth surfaces, this hygiene pallet boasts excellent cleaning properties, while the cavity-free construction offers reliable protection against contamination or water ingress. Characteristics: High load-bearing capacity for heavy-duty applications Patented welding seam geometry of the top and bottom deck as well as solid wall thicknesses ensure highest impact and breakage resistance Dimensionally stable with first-class bending parameters, ideal for roller conveyors and automated high rack warehouses Excellent cleaning properties Chamfered edges on both sides of all runners Options: Reinforcement profiles, for a load-bearing capacity of up to 2,000kg in high rack Rims: without, 7mm or 22mm RFID transponder

Request for a quote

CRAEMER GMBH

Germany

The H3 plastic pallet is the industrial-sized version of the H1 Euro pallet. This hygienic pallet is a proven choice primarily in the food and meat processing industry, however it is also suitable for transportation and storage of medium weight loads at temperatures down to -40°C in the non-food sector. The H3 plastic pallet is also available in a conductive version for use in the automotive, electrical and chemical industries as well as by their suppliers – to protect against electrostatic discharge (ESD). Characteristics: Available with 3 runners Ideal for medium weight loads High bending strength Ideal for transportation and bagged of sack goods or cardboard packaging Excellent cleaning properties Chamfered edges on both sides of all runners for optimal handling with fork lift trucks Options: Welded runners for a high standard of hygiene and smooth running on roller conveyors Rims: 7mm RFID transponder Palgrip® anti-slip coating under the runners ESD version

Request for a quote

CRAEMER GMBH

Germany

Original Palgrip® pallets from Craemer offer unparalleled smoothness and tracking on roller conveyors or chain conveyors. The abrasion-resistant anti-slip plates provide excellent slip resistance on the deck or under the runners. The high quality Palgrip® grain structure ensures an absolutely secure hold even in damp conditions. Palgrip® provides an all-round reliable solution to your logistical requirements. Only available from Craemer. The Palgrip® anti-slip coating is resistant to cold and heat, from -30°C to +40°C. Compared to common plastic surfaces, Craemer Palgrip® anti-slip sheets offer absolute slip resistance even in high humidity thanks to their grain structure. The unique Palgrip® anti-slip panels are made from high quality HDPE and are permanently part of the deck and the anti-slip runners will last the lifetime of the pallet. Even in an inclined position, your load remains static on the pallet deck

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Impregnation systems to close micropores in metal castings as well as in copper, aluminium or magnesium alloy castings. The parts to be impregnated are fixed in baskets. The latter are transported by a special crane system as well as with reservoir roller conveyors. Excess material is removed by centrifuging of the baskets. The impregnating agent remaining in the pores in fluid form is hardened by heating in a hot water bath. The process sequence runs fully automatically under a microprocessor control.

Request for a quote

TORWEGGE GMBH & CO. KG

Germany

Our solid gravity-driven roller conveyors provide an optimized solution for the internal transportation of your lightweight or heavyweight products. In order to ensure that your conveyed goods flow smoothly and independently all the way from the inlet to the outlet point, the roller conveyor must have the proper declination. This factor must be determined individually according to the type of load carrier and weight of the goods being used for your application. We can also deliver complete solutions that are individually tailored to your requirements; our support already begins during the planning phase for your project. Take advantage of our in-depth experience and benefit from our assessment of your operating conditions and influencing factors (including the suitability of using roller conveyors for your goods) – Leave nothing to chance.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

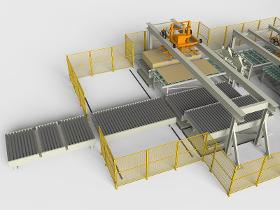

The boards to be coated are fed to the raw-board-handling section where they are separated to allow their surfaces to be cleaned. Features, function A forklift truck is used to place the board stacks on to a roller table from where roller conveyors or horizontal transfer carriages equipped with roller conveyors transport them to one of the two separating station's places. A suction carriage removes the top board from the stack and places it on a conveyor that takes it to the surface-cleaning machine. Advantages The two redundant stacking places allow the short-cycle press to be supplied without interruption. They make it possible to feed new stacks of boards without the need to shut the machine down

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

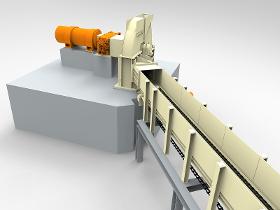

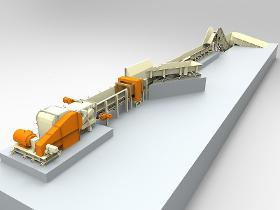

The line for tree-length logs is designed for the processing of whole logs with lengths of up to20 meters: With the log feed, debarker, washingsystem, dosing system all the way to the highlyecient disc chippers, the production of highquality chips is guaranteed Key featuresFeeding of the wood from the truck or storage areaLarge gantry or rotating cranes for loads of up to 30 metric tons of woodExtremely robust longitudinal chain conveyors or chip chutesLarge conveying cross-sections and laterally arranged chutesDrum debarkersChipper feeding onveyors for large throughputs Metal sensor and roller conveyor cleaning systemDisc chipperAdvantagesGentle de-barkingMinimal ne material content among chipsHigh safety against jamming of logs

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The scrap and short-wood line is designed for processing root pieces, slabs, edgings, panel waste pieces, windfall wood, and of course logs. With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-ecient drum chippers, the production of high-quality chips is guaranteed. Key features Simple feeding of wood directly from the truck Robust underground bins or vibrating feeders Vibrating conveyor lines Drum chipper Metal sensor and roller conveyor cleaning system Advantages Use of almost any type of wood material Continuous and uniform material feed Safe removal and discharging of rocks, sand, and other contaminants High lling level and high utilization of chipper capacity

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The long-wood line is designed for processing logs with lengths between 3 and 8 meters and diameters between 50 and 850 mm: With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-ecient disc chippers, the production of high-quality chips is guaranteed. Key features Feeding of wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the direct feed of logs Buer capacity of up to 30 minutes/ 80 metric tons bone dry material Step feeder for absolutely consistent volumes Metal sensor and roller conveyor cleaning system Rotor debarker for eective debarking even at extremely low winter temperatures Robust drum chipper Advantages Highly controllable wood feed Ecient debarking Perfect chip quality thanks to the adjustability of to the feed material mixture Minimal ne material content High lling level and high utilization of chipper c High operational safety

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The plantation wood line is designed for processing uniform wooden logs grown in plantations. These logs have lengths between 3 and 8 meters and diameters between 100 and 450 mm: With the log feed, dosing step conveyor, debarker, washing system, dosing system all the way to the highly-ecient disc and drum chippers as well as the mills for the preparation of bark, the production of highquality chips is guaranteed. Key features Feeding of wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the direct feed of logs Dosing step conveyor for absolutely consistent volumes Metal sensor and roller conveyor cleaning system Depending on the debarking demand, use of drum or rotor debarker Disk or drum chipper Advantages Robust, highly controllable wood feed Debarker adapted to the debarking demand Minimal ne material content High lling level and high utilization of chipper capacity High operational safety

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Roller transports, if required with workpiece transposition from one to two lanes, accumulation and disc roller conveyors or bar transport units complement our portfolio of continuous conveyor systems. VEN TRANS system techniques enable tailor-made workpiece conveying and handling concepts. We create Our solutions take into account

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Spiral rings are mounted on standard rollers and used to clean conveyor belts. When the idler roller rotates, the spiral rings move the dirt from the center of the belt outwards through a tumbling motion. The spiral rings (rubber rings) from FTK Förderband Technik Kilian GmbH are permanently fixed on the conveyor roller and are characterized by their abrasion resistant quality. In addition to the tried and tested standard, we also manufacture rings in special quality, e.g. B. white food quality, oil and fat resistant or for the extreme temperature range ( 40 ° C to 180 ° C).

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Support disks on idlers bridge larger distances to the conveyor belt. They support the belt and are preferably used in sidewall belts or profiled conveyor belts. The support disks (rubber rings) from FTK Förderband Technik Kilian GmbH are permanently fixed on the conveyor roller and are characterized by their abrasion resistant quality. In addition to the tried and tested standard, we also manufacture rings in special quality, e.g. B. white food quality, oil and fat resistant or for the extreme temperature range ( 40 ° C to 180 ° C).

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Buffer rings absorb the falling energy of the conveyed goods and thus protect the belt from damage. The buffer rings (rubber rings) from FTK Förderband Technik Kilian GmbH are permanently attached to the conveyor roller and are characterized by their wear resistant quality. In addition to the tried and tested standard, we also manufacture rings in special quality, e.g. B. white food quality, oil and fat resistant or for the extreme temperature range ( 40 ° C to 180 ° C).

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

We manufacture and deliver the complete range of simple carrier roller holders, e.g. for the lower belt roll and 2 or 3 part upper belt stations in all trough angles. We are happy to manufacture and deliver simple to complex upper belt steering stations. We offer you Let us know when you inquire whether we should offer the conveyor roller stations in a primed, painted, galvanized or special version.

Request for a quoteResults for

Roller conveyor - Import exportNumber of results

35 ProductsCompany type

Category

- Conveyor belts (11)

- Conveyor systems (7)

- Pallets (5)

- Wood veneer - machinery and equipment (5)

- Rubber products (3)

- Handling - Machines & Equipment (2)

- Rolling machines (2)

- Travelators (2)

- Steels and metals - forming and cutting (1)

- Boring - steels and metals (1)

- Goods handling systems, continuous (1)

- Parking lots - equipment (1)

- Surface treatment - machinery and equipment (1)

- Transportation chains (1)