- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ring

Results for

Ring - Import export

PIERON GMBH

Germany

Dimensions Wire diameter: 0,2 – 8,0 mm Outside diameter: > 120 mm after consultation All wire profiles feasible Material All spring materials and quality steels with lower strengths Coating All commonly coated spring steels In-house phosphating In-house stove-enameling Additional coatings through external services Specialities Clamping rings made of round wire or flat material Clamping rings with a stamp Rings with defined bendings Minimum burr cut-geometry Additional processing available after consultation Customer specific packaging Rapid prototyping

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Westfälsche Drahtindustrie GmbH uses highly efficient plant technology at its Salzgitter site to produce cold-ribbed reinforcing steel (CR) in rings and coils, as well as structural steel mesh. Thanks to special wire rod primary material for our CR products, which we have developed in close cooperation with our suppliers, our reinforcing wire achieves first-class technical values, particularly in terms of elongation and the Re/Rm ratio The advantages for the user: easy processing and dimensional accuracy of the hangers. Seamless quality monitoring from the wire rod to the finished product by our own quality centre and our external monitoring centre (MPA Dortmund) guarantees the highest level of lasting quality and safety.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

A snap or retaining ring is a fastener or retaining ring that consists of a semi-flexible metal ring with open ends that can be snapped into place. It fits in a groove on a shaft or inside a bore and locates the shaft axially in one direction.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Circlips and Locking Rings consist of a semi-flexible metal ring with open ends that can be snapped into place. They fit in a groove on a shaft or inside a bore and locates the shaft axially in one direction.

Request for a quote

HEBMÜLLER GMBH

Germany

As high-performance plastics, we mainly use PTFE with various fillers such as bronze, glass fiber or carbon. For special applications, we also offer sealing rings made of PAI or PEEK.

Request for a quote

HEBMÜLLER GMBH

Germany

We have specialized in R-rings SH according to DIN 34109 / DIN34110 / DIN34118. In addition to the hook joint (SH), we mainly supply with straight joint, overlapped joint (SU) or gas-tight joint (SG or SW).

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Removal of determined locking ring class (double removal) with control measurement and transfer to assembly station Locking ring assembly and testing (cycle time approx. 30 sec.)

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the fastener rings made by brass.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Mechanical parts - washers.

Request for a quote

IGUS® GMBH

Germany

When to use piston rings? When piston rings with excellent wear properties are required When simple assembly is of great importance When high edge loads occur When tailor-made solutions based on iglidur® materials are required When not to use piston rings? When the piston rings should seal simultaneously When different diameters should be covered by one part Before: with piston rings: Why complicate things when it can be done differently? Replace elaborately stamped PTFE tapes with a single clip-on guide ring, such as in lifting elements, control valves and fittings. We offer iglidur® piston rings made of freely selectable materials for a wide range of applications. Special properties Easy to assemble Low-priced More wear-resistant than PTFE-bonds Higher load capacity Defined dimensions different materials per ex. iglidur® J, J350… iglidur® piston rings - application examples When to use piston rings? When piston rings with excellent wear properties are required When simple assembly is of great importance When high edge loads occur When tailor-made solutions based on iglidur® materials are required When not to use piston rings? When the piston rings should seal simultaneously When different diameters should be covered by one part Installation recommendations pistons installation recommendations for housings Installation recommendations for housings Dimensions [mm] dS (h-tolerant) [mm] dG (h-tolerant) [mm] bg [mm] Nominal diameters dS = d1 dG = d2 bG = b1 +0,2 Installation recommendations for pistons Dimensions [mm] dG (h-tolerant) [mm] dH (h-tolerant) [mm] bg [mm] Nominal diameters dG = d1 dH = d2 bG = b1 +0,2 b1: Desired length Inner and outer Ø (d1 and d2) made using standard plain bearings* M for metric PRfor piston ring iglidur® desired material

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Most common ends are different types of end loops and hooks, there are also a wide range of other mechanical attachment possibilities such as coiled in and screwed in attachments. Examples are, half hooks, German loops, English loops, extended hooks, side hooks, side loops, screw plugs and screw shackles.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

A clamping ring machine is a system for the automatic production of clamping rings. Schmale Maschinenbau Gmbh is one of the leading manufacturers of clamping ring machines in Europe. On our clamping ring machines, the strip material is profiled, bent and cut. Automatically closures are supplied and welded. The finished clamping ring is calibrated and stored. Via a servo-electric transfer, all processing stations are connected to each other and operated simultaneously. Thus, cycle rates of up to 28 clamping rings per minute can be realized.

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

steel, 8 mm Ø*zinc plated*three point support

Request for a quote

BS BODENSTECKDOSEN SYSTEMTECHNIK GMBH

Germany

Aluminum leveling ring 12251 for floor socket 7702A and 7704A for use in wooden floors or raised access floors. The leveling ring is attached to the floor socket with screws and screwed onto the floor from below. The delivery takes place with grub screws, but without illustrated fastening screws and illustrated floor socket.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Rotary shear knives made from tool and PM steels in the highest OEM quality with a hardness of up to 60 HRc. CNCcontrolled machines guarantee you tight and consistent form and position tolerance for the knives. Inquire now.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We manufacture customer-specific molded parts made of rubber, silicone and elastomer composite parts in small and large series production according to your sample or drawing. Molded rubber parts are generally characterized by their good formability, chemical resistance, pressure and abrasion resistance and good electrical properties. We advise you in detail on the selection of the suitable material, with a view to the functional description, temperature resistance, chemical requirements, weather influences and resilience. Our molded parts are used in all industries, such as the automotive industry, medical technology, mechanical engineering and electronics industry. We offer customized parts: Protective covers for input devices, Rubber seals and rings, Grommets, flanges, bellows, Form Tubes, Rubber damper, PU molded parts (e.g. wheels and rollers) Combined rubber-metal parts / rubber-plastic parts, etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CARL FRIEDRICH USBECK KG

Germany

powdercoated*wire Ø 4 mm*nickel plated brass screw

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

steel, 8 mm Ø*zinc plated*three point support*nickel plated brass screw

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Customised system or individual part solutions are our core competence at KIS. We develop complete solutions for you based on our own KIS products and combine them with our comprehensive service for drive technology. Whether it's a careful selection of individual components or proper assembly ensuring your application functions perfectly: As bearing specialists based in Germany, we’re there for every step of the process, from development and construction, through monitoring of production and assembly, to quality inspections and practical tests.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our KIS slewing rings offer precise rotation technology to reliably connect two or more parts in your application. They are available in a wide variety of designs. As high load-bearing machine elements, they can safely absorb radial, axial and tilting moment loads with one bearing point and thus significantly reduce the effort required for the design of the adjacent construction. Sealed and lubricated, our slewing rings offer long-term performance even under demanding operating conditions. They are used in the fields of mechanical engineering, automation and robotics, among others. We are happy to work with you to develop the right slewing ring for your specific application requirements.

Request for a quote

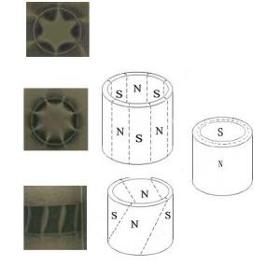

STRONG MAGNETS GMBH

Germany

Neodymium ring magnet ais also known as tube magnet, a round disc magnet with a straight hole along the centre, the hole in centre ensures great versatility. Most ring magnet is with north and south poles on the flat circular surfaces (this is called as axial magnetisation). The few exception that is diametrically magnetised is specifically marked. Also, Multi pole ring magnet, even radially magnetized ring magnet, is more and more referred in this industry now. Ring magnet is being designed into a new generation of motors, generators, hydraulic cylinders, pumps & sensors, rotor shafts and more. What's more, it remains very popular in high end loud speakers and high intensity separators. We are ready to make a custom ring magnet for your application, welcome to contact us for a further communication.

Request for a quote

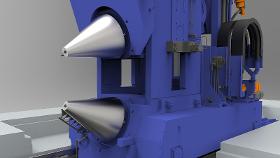

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

With the ring rolling mill Siempelkamp completes its range of products for the manufacture of rings. From forging the pre-forms to manufacturing the ring blanks to ring rolling, we supply everything from a single source. Siempelkamp’s ring rolling mill manufactures seamless rings made of steel and special materials such as nickel-base, titanium, or aluminium alloys using maximum radial and axial pressing forces. The radial pressing force is hydraulically generated and applied to the part via a mandrel roll. Radial rolling is carried out by reducing the roll gap between the driven external roller and the mandrel roll. The axial pressing force is also hydraulically generated and applied to the part via the upper axial roller. Axial rolling is carried out by means of the vertical forward feed of the upper axial roller. A centring device provides for the correct position of the ring during the rolling process.

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Application areas for straightening presses include the sheet metal processing industry. Here, this type of press is used for the straightening of semi-nished products, such as the levelling of uneven sheet metal and slab surfaces, which are used in subsequent processes. In addition to high straightening accuracy, Siempelkamp straightening presses provide a broad straightening spectrum and high exibility in the further processing of sheet metal. For materials with a tensile strength of 1,300 N/mm2, sheet metal with a thickness of approx. 300 mm can be processed To do so, the presses are equipped with one or several straightening rams which can be operated together or individually. The pressing force needed for straightening is applied across the entire press width. Sheet metal can be straightened by cold or warm forming with sheet temperatures of up to 600°C.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

As the leading provider of metal forming presses we are setting the standard worldwide. Our expertise in plant engineering and process technology is unique. This is because the individual performance features from the design to the startup of the equipment create a coherent and complete solution from a single source. Our hydraulic presses for metal forming are at home in cold and hot forming. From turbine disks for aircraft to pipeline pipes in the oil and gas industry to longitudinal beams in trucks: In our key industries of automotive, energy, rail and aerospace, we offer the right solution for every product. We supply not only the press, but also the associated process technology. Our range of services includes forging, thick sheet metal forming, raw forming, sheet metal forming and ring rolling. Our special systems for metal forming offer the perfect balance between the use of standard components and a custom-made design.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The quality and consistency of akes have a signicant inuence on board properties. Knife-ring akers are exible and can be individually adjusted to meet aking requirements. The professional preparation of chips leads to the right akes for particleboard. Features, Function Chip feed system with vibration chute and magnetic drum Integrated heavy particle separator Impeller used to distribute chips Counter-rotating principle of the knife ring Chip width adjustable by knife protrusion Bottom discharge Advantages Consistent ake quality High throughput rates Quick knife changes Precise knife adjustment Uniform utilization of all knives No clogging even at high moisture content Economic to operate and maintain Robust, reliable, and durable

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Industrial Grate-ring systems are used very often in processes involving energy generation with solid fuels. Büttner's grate-ring energy systems are individually customized to the operator's needs and are exible when it comes to the fuel needed – whether it be waste wood, bark, or chips. Key features: fuels with a moisture content level between 20 - 150% based on bd combustion of waste wood (A1 - A3), wooden board wastes (MDF, PB and OSB), bark, wood chips, co air-cooled step grate sized from 12 to 90 m² ring capacity from 10 - 100 MW automatic de-ashing system graduated air-inlets low emissions

Request for a quoteResults for

Ring - Import exportNumber of results

40 ProductsCompany type

Category

- Components and parts for small household appliances (4)

- Magnets (3)

- Forming - steels and metals (3)

- Import-export - steels and metals (3)

- Laboratory equipment and instruments (3)

- Sealing rings (2)

- Rubber products (2)

- Piston rings (1)

- Bearings - ball, needle and roller (1)

- Seals (1)

- Bearings, roller (1)

- Moulds, plastic and rubber industry (1)

- Springs (1)

- Cork products (1)

- Driveshafts and micro-motors - electric (1)

- Electronics - import-export (1)

- Energy - production plants and equipment (1)