- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- profile bars

Results for

Profile bars - Import export

ROLLON GMBH

Germany

The ECO SYSTEM units are linear actuators made of a self-sustaining extruded aluminum frame and are driven by a polyurethane belt with AT metric profile steel inserts. Three different sizes available: 60mm, 80mm, 100mm Version available with recirculating ball bearing or roller rails Reduced weight ensured by the light frame and the aluminum sliders High sliding speed The ECO SYSTEM series actuators are offered with two motion systems: ECO SYSTEM – SP Featuring a maintenance free recirculating linear guide rail fitted inside the profile. ECO SYSTEM – CI Featuring four rollers with a Gothic arch outer profile sliding on hardened steel bars placed inside the profile. Main fields of application for Eco System linear units: Automation Packaging Industrial machinery

Request for a quote

FRIEDR. FREEK GMBH

Germany

Advantages of Heating Plates with Square Cartridge Heaters: -> Simple plate manufacture due to rectangular groove geometry, no deep-hole boring -> Simple heater installation by bending and pressing along the plate surface -> Complex plate geometries with bores and openings -> Optimal heat transfer due to 75% surface contact -> No casting with heat conductive compound -> Uniform temperature profiles due to thermally optimized groove layouts/power distribution and utilization of insulation plates -> high process temperatures (up to 450°C in aluminium, up to 700°C in stainless steel) Example "Heated Stamp": D=100 mm out of tempered tool steel up to max. 700°C continuous temperature. Fitted with 2 Square Cartridge Heaters 1500 W/ 230 V, 4,5 x 4,5 mm x 600 mm, with 50 mm unheated at the termination end. Annealed and formable with a nickel sheath, resistant up to 850°C surface temperature. Connection by fibreglass insulated pure nickel high-temperature leads (max. 500°C)

Request for a quote

ALUMINIUMWERK UNNA AG

Germany

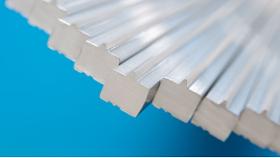

With the unique extrusion process, ALUnna has the capability to produce continuous lengths of extruded profiles. Unlike the conventional extrusion process, the continuous extrusion process does not use billets. Instead, raw material is fed into the process from a coil. This process is especially useful for the production of small extrusion profiles used as spacer bars in alloys EN AW-1050A / 1350A or EN AW-3103/3003. If necessary, there is an option to apply a draw pass to the spacer bar profile using an in-line Schumag continuous drawing machine in order to achieve the final dimension and the most demanding of tolerances.

Request for a quote

SPANSET SECUTEX GMBH

Germany

Wipers for steel bars In the production of pipes and steel bars, socalled wipers are used for leaning. The wipers have a round or rectangular outer profile and an inner profile that matches the shape of the object to be cleaned. Normally, several wipers are mounted in series, whereby the passthrough openings are smaller than the profile. The bar is pushed through the elastomer plates at high velocity, and the rubbery material strips the surface free from grease and cleaning fluid residues. It is the edge that counts! Just a like a car window wiper, it is the edge that counts. Normally, the wipers are stamped from sheet goods. During stamping, the elastomer becomes distorted; the inner edge is therefore not dimensionally stable and is at an angle. Only part of the edge wipes emulsions from the surfaces depends on the profiles. This edge is rapidly worn down; the cleaning action is then unsatisfactory. Streakfree cleaning

Request for a quote

GSW SCHWABE AG

Germany

high accuracy for feed repeat of +/ 0,05 mm high clamping force to serve even large material crosssections serving a wide variety of materials, such as coil, band, bar or profile stocks or even wires, cardboards, papers and fabrics operation in push or pull mode or combined in pushpull mode special air cylinder design for reduced air consumption feed length adjustment via finethreaded spindle

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SPANSET SECUTEX GMBH

Germany

Wipers for steel bars In the production of pipes and steel bars, socalled wipers are used for cleaning. The wipers have a round or rectangular outer profile and an inner profile that matches the shape of the object to be cleaned. Normally, several wipers are mounted in series, whereby the passthrough openings are smaller than the profile. The bar is pushed through the elastomer plates at high velocity, and the rubbery material strips the surface free from grease and cleaning fluid residues. It is the edge that counts! Just a like a car window wiper, it is the edge that counts. Normally, the wipers are stamped from sheet goods. During stamping, the elastomer becomes distorted; the inner edge is therefore not dimensionally stable and is at an angle. Only part of the edge wipes emulsions from the surfaces depends on the profiles. This edge is rapidly worn down; the cleaning action is then unsatisfactory. Streakfree cleaning

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Around installation technology, cable clamps for the fastening of HF cables to telecommunication masts are our speciality. These cable clamps consist of a C frame including retaining feet (for installation on to a C-profile or flat bar) and a fastening screw with grouted thrust washer. In addition, the corresponding number of cable trays (inlays) are supplied. C frame The C frames are stamped bent parts which – depending on their size – have lateral pieces to provide rigidity and stability. The fixing screws have a uniform hexagon head. Due to the construction and material selection, after tightening, a secure hold is ensured even without a lock nut. A torque of 1.5 Nm is recommended here. Installation to flat bars is possible up to a material thickness of 9.3 mm. Inlay The cable troughs are chamfered for side installation or simple setting into the C frame. The wide overlap protects against falling through before tightening the fastening screw.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Westfälische Drahtindustrie produces cold rolled flat and shaped wires at its Brotterode site. Over the last few decades, the Brotterode plant, with its central location in the heart of Europe, has evolved into an important supplier to the international cold rolling industry. With around 40 employees, we manufacture flat and profile wires in coils or bars for our industrial customers at our site in Brotterode (Thuringia) - on an area of 40,000 m². Our products can be found in the offshore, construction, electrical and automotive industries, among others. The Brotterode plant maintains quality assurance in accordance with ISO 9001 and certified energy management in accordance with ISO 50001. The absence of an environmentally harmful pickling plant also makes us an environmentally friendly high quality flat wire plant

Request for a quote

NAGLER NORMALIEN GMBH

Germany

Bronce bars, sheets profiles und defferent alloys

Request for a quote

NAGLER NORMALIEN GMBH

Germany

Molybdenum bars, sheets profiles und defferent alloys

Request for a quote

NAGLER NORMALIEN GMBH

Germany

Aluminum bars, sheets profiles und defferent alloys

Request for a quote

NAGLER NORMALIEN GMBH

Germany

Tungsten bars, sheets profiles und defferent alloys

Request for a quote

PROFORM GMBH

Germany

For use inside and outside, for manufacturing or retrofitting windows with bars. Bar profile in white tones or covered in foil with lips in black, grey and white, weather-resistant and anti-aging foam tape. Window bars in PVC U window quality, new goods. With RAL-tested TPE soft lip material. Acrylate foam tape quality, weather-resistant and anti-aging, permanently elastic, certified by ift-Rosenheim. Wood and one-colour decorative window bars covered in weather-resistant and anti-aging Renolit MBAS or Cova foil. Window bars can be used with and without spacers (Georgian bars) in insulating glass.

Request for a quoteResults for

Profile bars - Import exportNumber of results

14 ProductsCompany type

Category

- Foundries - copper, bronze and brass (4)

- Aluminium alloys (1)

- Cables - accessories (1)

- Electroheat - machines and equipment (1)

- Food industry packaging machinery (1)

- Internal transport systems (1)

- Machine tools, metal shaping - parts and accessories (1)

- Steel & Metal Transformation (1)

- Windscreen wipers (1)

- Wires and cables, steel (1)