- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- product data

Results for

Product data - Import export

BORNEMANN GMBH

Germany

Machine type holders, also called type holders, are flexible tools for labelling with figures or letter combinations, batch numbers, production data as well as manufacturer logos. The size of the type holder depends on the surface provided and the labelling required. The machine type holders can also be designed on several lines. As a rule, the clamping is carried out with lateral tensioning screws, but T types and L types are also used. We make this product according to your wishes.

Request for a quote

BORNEMANN GMBH

Germany

Machine dies or special dies with a set geometry on the basis of customer data for labelling complex surfaces. Nearly every surface can be displayed. State-of-the-art cad/cam programs support us in the production process. The data you send in are processed by us and then input into our CNC engraving machine.

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

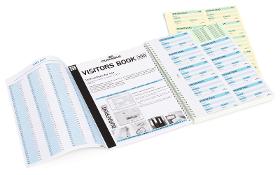

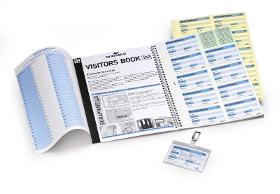

Refill set for 300 visitor passes. Suitable for visitor’s book item no. 1465. • Refill set for visitor book product # 1465 • Micro-perforated data sheets for 300 name badges • Secure recording of visitor data thanks to three-part set of papers • Dimensions of insert sheets: 90 x 60 mm (W x H)

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Refill set for 100 visitor passes. Suitable for visitor’s book item no. 1463. • Refill set for visitor book product # 1463 • Micro-perforated data sheets for 100 name badges • Secure recording of visitor data thanks to three-part set of papers • Dimensions of insert sheets: 90 x 60 mm (W x H)

Request for a quote

BERNSTEIN AG

Germany

The SRF (Safety RFID) is a non-contact safety sensor, that monitors moveable safety guards, such as doors, flaps and hoods. With its innovative diagnostic system, the SRF makes safety circuits suitable for Industry 4.0. The system provides a multitude of diagnostic data of each sensor, even in a series connection, to support smart production. Diagnostic data is fed into the machine control system via I/O Link or alternatively displayed on a smartphone by way of NFC technology. In this way, 20 different diagnostic information of each sensor can be retrieved and made available. This diagnostic data delivers cost-effective predictive maintenance in a simple way. Through its advanced fault recognition capability, costly machine shutdowns can be prevented. This way, your machinery and plant will work even more efficiently!

Request for a quote

FRIWO GERÄTEBAU GMBH

Germany

Enable-Tool NG Professional is used for the adjustment and maintenance of our control units in development, production and after - Read error memory - Setting of a limited number of parameters per control unit - Creation of signed data records for production and aftersales - User roles (developer, production, service) for controlling vehicle projects in larger organizations with a dealer network - Creation of signed data records for production and aftersales - Storage and transmission of data sets - Interface to End-of-Line Test Additional information •Interface: USB •System requirements: Microsoft Windows, Dualcore CPU @ 1.8 Ghz, 2GB RAM, 100MB HDD •Read fault codes: Service and developer •Change parameters: Developer •Create datalog: Service and developer •Create data snapshot: Developer •Transfer data snapshot on a certain OEM ECU: Service •Transfer data snapshot all OEM ECUs: Developer •Connectivity: Active online connection

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Product data - Import exportNumber of results

6 ProductsCompany type