- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure tanks

Results for

Pressure tanks - Import export

JERKO-SPRÜHSYSTEME GMBH

Germany

Mobile, compact and multifunctional. Whether as manual spraying equipment or as compact solution for experiments. The compact pressure vessels with up to 18 litres useful volume are suitable for all tasks. The particularly easy handling makes these containers a popular entry-level solution.

Request for a quote

GSW SCHWABE AG

Germany

electric compact control with one or two 10l pressure tanks pressurized dispensation made especially for high viscosity lubricants pulsedependent flow control (0 – 99 pulses/min) dispensation time and delay after the incoming signal electrically adjustable via initiator

Request for a quote

ELKON GMBH

Germany

In some countries, cement is widely delivered by railway. The cement carried in wagons can be transferred to the cement silos with special pneumatic cement feeding system developed by ELKON. ELKON Cement Delivery System from Railway consists of wagon feeding hopper, intermediary feeding screw, material holding tank, pressure tank, compressor and control panel. The system which has a cement feeding capacity of 50 tons / hour can also be used to feed a large number of cement silos.

Request for a quote

ELKON GMBH

Germany

Cement material supplied with big bags or bags can be transferred into cement silos by means of ELKON Big Bag/Bag Pneumatic Cement Feeding System. ELKON Big Bag/Bag Pneumatic Cement Feeding System consists of cement feeding hopper, intermediary feeding screw, pressure tank, compressor, loading crane and control panel. This feeding system, which has a capacity of 15 tons/hour, is equipped with 2 tons crane to lift the big bags and dispatch into the feeding hopper. The complete set of ELKON Big Bag/Bag Pneumatic Cement Feeding System fits into 1 unit 40’OT container and thus it can be easily transported to overseas countries.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The OPTIBAR PC 5060 is a pressure transmitter for process pressure and hydrostatic level measurement in all kinds of process applications. It is designed for absolute and gauge pressure measurement in open tanks and – as dual version for electronic differential pressure measurement – also in closed vessels. The pressure device features a ceramic capacitive measuring cell that guarantees maximum overload and vacuum resistance for high plant availability. The measuring cell can be built into the process absolutely flush and the radially recessed position of the gasket provides additional protection in abrasive media. It is resistant to sudden temperature shocks and can handle operating temperatures of up to +150°C/ +302°F. The OPTIBAR PC 5060 comes with robust plastic and aluminium housing or hygienic stainless steel versions (incl. ingress protection IP69k). The pressure transmitter comes with various diagnostics and digital communication options.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JERKO-SPRÜHSYSTEME GMBH

Germany

Mobile, compact and multifunctional. Whether as manual spraying equipment or as compact solution for experiments. The compact pressure vessels with up to 18 litres useful volume are suitable for all tasks. The particularly easy handling makes these containers a popular entry-level solution. By using proven components, the spray unit is perfectly suited for long-term use. The pressure tanks with a self-developed circulation system are also suitable for spraying lubricants or coatings with solid content. For particularly easy transport, all pressure vessels can be equipped with a chassis.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Visual fluid level indication in hydraulic reservoirs with maximum tank pressures not exceeding 2 bar / 29 PSI; ideal for custom applications in terms of reservoir capacities and dimensions Nominal Sizes ▪ Special sizes beyond the normal of 305 mm / 12 in up to a maximum nominal size of 950 mm / 37.4 in – even for small and medium quantities ▪ High-precision manufacturing within 1 mm tolerance to customer requirements Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Designs ▪ Robust design thanks to one or more struts that subdivide the display into 2 or more sections ▪ Positioning of the strut(s) based on engineering considerations and/or according to particular customer requirements ▪ Precise visual indication of the fluid level by use of scale plates (only available for nominal sizes smaller than 670 mm / 26.4 in) or by use of a coloured floating element (recommended option for nominal sizes larger than 670 mm /...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Visual / electrical fluid level indication in hydraulic reservoirs with maximum tank pressures not exceeding 2 bar / 29 PSI; ideal for applications in which space is limited Nominal Sizes and Designs ▪ 5 nominal sizes from 127 mm / 5.00 in to 305 mm / 12.00 in ▪ Compact design allows space-saving installation: ▪ Always 40 mm / 1.57 in shorter than Level Gauges SNK of the comparable nominal size ▪ Display either undivided (SNKK 127 ... 176) or subdivided by strut(s) into 2 (SNKK 254) or 3 sections (SNKK 305) Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Materials ▪ Housing made of Aluminium, black powder coating ▪ Sight tube and plugs made of Polyamide (PA) ▪ Float made of Polyamide (PA) ▪ Sealings made of FPM (Viton®) Special sight tube materials for improved UV or chemical resistance and use with special media (such as bio-degradable fluids, diesel oils, gasolines, etc.) as well as special sealing materials are...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Visual / electrical fluid level indication in hydraulic reservoirs with maximum tank pressures not exceeding 2 bar / 29 PSI Nominal Sizes and Designs ▪ 5 nominal sizes from 127 mm / 5.00 in to 305 mm / 12.00 in ▪ Display either undivided (SNK 127 ... 176) or subdivided by strut(s) into 2 (SNK 254) or 3 sections (SNK 305) Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Materials ▪ Housing made of Aluminium, black powder coating ▪ Sight tube and plugs made of Polyamide (PA) ▪ Float made of Polyamide (PA) ▪ Sealings made of FPM (Viton®) Special sight tube materials for improved UV or chemical resistance and use with special media (such as bio-degradable fluids, diesel oils, gasolines, etc.) as well as special sealing materials are available on request. Electrical Specifications ▪ Magnetic float activates switch when fluid level drops below contact level within 60 mm / 2.36 in of lower banjo bolt ▪ Available as a break contact...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Visual fluid level indication in hydraulic reservoirs with maximum tank pressures not exceeding 2 bar / 29 PSI Nominal Sizes and Designs ▪ 6 nominal sizes from 76 mm / 2.99 in to 305 mm / 12.00 in ▪ Display either undivided (SNA 076 ... 176) or subdivided by strut(s) into 2 (SNA 254) or 3 sections (SNA 305) Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Materials ▪ Housing made of Steel St 12, black powder coating ▪ Sight tube and plugs made of Polyamide (PA) ▪ Sealings made of NBR (Buna-N®) ▪ Scale plate made of PVC Special sight tube materials for improved UV or chemical resistance and use with special media (such as bio-degradable fluids, diesel oils, gasolines, etc.) as well as special sealing materials, e.g. FPM (Viton®), and scale plate materials, e.g. Aluminium, are available on request. Technical Data ▪ IP 65 protection rating: Dust tight and protected against water jets (IP 67 on request) ▪ Operating temperature...

Request for a quote

OGE GROUP

Germany

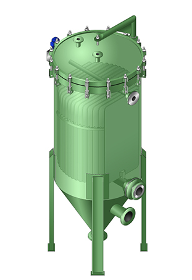

Horizontal Pressure Leaf Filters The Horizontal Pressure Leaf Filters are an efficient system for Solid-Liquid separation where a high filtration surface is required. Easy to operate and maintain, they are essentially composed of filtering elements and cleaning devices installed in a pressure tank.

Request for a quote

OGE GROUP

Germany

Pressure Filters The Filter is composed of a pressure tank containing the filtering elements and the washing device or dry cake removal system. The filtering elements are vertically mounted cloth covered plates in Stainless Steel/Titanium/PVC/PE/PP (so called leaves) or special candles (made in plastic materials or stainless steel).

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The application of CO 2 ice jet spraying is convincing. Ranging between CO 2 cleaning and high-performance dust removal with regard to quality, optimum pretreatment can be accomplished with this system variant, only requiring simple workpiece fixing and little noise protection measures. DUST FREE can be flexibly integrated in existing equipment. A cleaning jet consisting of a mix of compressed air, CO2 and CO2 ice particles causes the soiling on the surface to become brittle. The thermal tension loosens cohesion and detaches the soiling from the workpiece surface. The cleaning jet guarantees the removal of soiling without residue. The DUST FREE and PERFECT applications optimally meet the requirements of the subsequent downstream surface quality, offering maximum thoroughness from dust removal through to cleaning. This process allows gentle cleaning of virtually all components, therefore, it is an alternative to aqueous power washing. Patented detail solutions form the basis for this mature system technology. Small workpieces are reliably held in place by the special hold-down system. The Venjakob pump station developed for this task guarantees the process reliable supply of liquid CO 2 from a low pressure tank system to the cleaning module. A clear advantage of the CO2 cleaning system over the conventional aqueous cleaning process is its relatively small space requirement. Additional decisive advantages of this system are:

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Efficiency and quality of this innovative cleaning system are impressive, from the three-dimensional small parts to large format workpieces in large batch sizes. The performance of the CO2 ice jet is especially convincing when cleaning plastic workpieces. The shown surface plant offers optimum noise emission values of approx. 80dB(A) due to the patented noise protection system comprising follower-type bulkhead partitions. A cleaning jet consisting of a mix of compressed air, CO 2 and CO 2 ice particles causes the soiling on the surface to become brittle. The thermal tension loosens cohesion and detaches the soiling from the workpiece surface. The cleaning jet guarantees the removal of soiling without residue. The DUST FREE and PERFECT applications optimally meet the requirements of the subsequent downstream surface quality, offering maximum thoroughness from dust removal through to cleaning. This process allows gentle cleaning of virtually all components, therefore, it is an alternative to aqueous power washing. Patented detail solutions form the basis for this mature system technology. Small workpieces are reliably held in place by the special hold-down system. The Venjakob pump station developed for this task guarantees the process reliable supply of liquid CO 2 from a low pressure tank system to the cleaning module. A clear advantage of the CO 2 cleaning system over the conventional aqueous cleaning process is its relatively small space requirement.

Request for a quote

GLÄSNER SANDSTRAHL MASCHINENBAU GMBH

Germany

The housing is made of folded stable sheet steel and welded. In the cabins 2 workports with built-in rubber sleeves (easily exchangeable) are incorporated. The cabin is equipped with a blast hose, nozzle holder and nozzle 1 made of hard metal. For the different requirements are made of hard metal nozzle with a diameter of 0.8 mm, 1.0 mm or 1.2 mm for selection. All blasting medium-pressure vessel (1 - 3 Tank System) have a volume of 2 kg and provided with a closure cap. In all systems, a pressure reducing valve and a pressure gauge for setting a constant jet pressure, and compressed air supply are fitted with plug-in nipple. All systems are equipped with a pneumatic foot switch for turning on and displaying the blasting process.

Request for a quoteResults for

Pressure tanks - Import exportNumber of results

16 ProductsCompany type