- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure reducers

Results for

Pressure reducers - Import export

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

SPANSET SECUTEX GMBH

Germany

Again and again, coils with larger internal diameters than expected have to be processed on coilers. Here the secutex coiler sheath offers a simple and flexible solution to the problem. Enlargement of the internal diameter The handy secutex coiler sheath is simply pushed onto the coil mandrel and enlarges the radius to the required size. The timeconsuming assembly of subcomponents is no longer necessary. Prevention of dents Thanks to the high friction of the secutex material, the coil cannot slip and, in some cases, the contact pressure can be significantly reduced. The typical impressions in the initial winding layers are prevented and material wastage is significantly reduced. The secutex material is extremely wearresistant and, unlike standard rubber, is also oilresistant. The insertion tip helps thread the coils.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Immersion Pumps Models TS12 to TS24 are suitable for CNC machine tools featuring coolant supply through the tool holder or driving spindle or equipped with internally cooled tool. These pumps are equipped with a peripheral impeller to achieve a compact high pressure unit. Series TS are suitable for filtered coolant only. To reduce pump pressure, models TS22 to TS24 are also available with an optional Y/YY (Dahlander) motor configuration for 4 pole operation at half speed. Volumetric delivery: up to 70 l/min Delivery head: up to 95 m Please contact us for delivery quantity

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

You require a mobile steam plant or you want to install a steam plant outside your plant building? Then the complete installation within a container is the ideal solution for you. The container steam plant contains all the required components – from the water treatment plant through to the steam trap. - CERTUSS steam generator - CERTUSS CVE supply unit - Feed water treatment - Steam distributor - Pressure reducer station - Clarification valve - Steam dryer - Condensate elevating system - Steam trap - Interior lighting of the container - Insulated pipe installation in the container - Emergency-off switch - Steel door or uPVC door - High-quality stainless steel wall with insulation - Outside coating as required The installation and commissioning of the container plant at the customer is on request either carried out completely or only partially (if an external installation company is used) by our customer service.

Request for a quote

TAS SCHÄFER GMBH

Germany

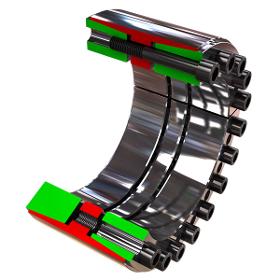

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quoteResults for

Pressure reducers - Import exportNumber of results

37 ProductsCompany type