- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- presses for sheet metal forming

Results for

Presses for sheet metal forming - Import export

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our isothermal forging presses produce sophisticated, heavy-duty components for high-tech products. We furnish our customers with rst-class solutions including control systems for the ne-tuning of pressing speeds. Our presses are designed for high-precision applications indispensable in the aircraft/aerospace and medical engineering industries. The challenge here is to manage pressing speeds of 0.01 mm/s in controlled operation, which is ensured by our own electrical and hydraulic control engineering Siempelkamp also oers plants to be used for isothermal forging. They comprise the furnace, the feed manipulator, the forging press, the die heater, the hydraulic drive system and the entire automation technology. The plant control for isothermal forging presses monitors and documents the process parameters in compliance with the certication standards to be observed in the aircraft industry.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The O-forming press applies a press force of 4,000 metric tons per meter of pipe. This is necessary to form today’s material grades above X100 to the desired round shape at the optimum level of reduction. The control concept with (patented) multi-cylinder parallelism control ensures that the moving beam maintains a position parallel to the press table with a tolerance of +/-1 mm/m over the entire length. Combined with our tools, this results in a precise pipe gap which leads to signicant time and material savings for the subsequent welding process. The intelligent sensor and control concept of all main cylinders ensures that dierent sheet lengths (e.g., residual lengths) can be processed. The press is powered by either conventional drive concepts or via frequencycontrolled drive concepts. Our ECO Drive uses the high moving load of the moving beam to generate energy during the controlled quick lowering of the beam. This energy is fed back to the power network.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

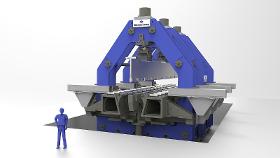

Siempelkamp is number one in tailor-made plants for the leading manufacturers of pipeline pipes. These large-diameter pipes with longitudinal weld seams are manufactured using crimping, U-forming, and O-forming presses. Compared to other processes on the market, these three presses achieve high production outputs of up to 30 pipes per minute regardless of the pipe diameter. For these large presses featuring our proven metal frame construction, the heavy component parts and tools are manufactured in our in-house foundry. The three hydraulic presses present the essential forming units of a modern production line for longitudinally welded pipes with lengths of up to 18 m in three forming steps. For each of the three forming steps, Siempelkamp oers the optimal press and the associated equipment for the forming line (e.g., pipe transport, lubrication, measuring).

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

As the leading provider of metal forming presses we are setting the standard worldwide. Our expertise in plant engineering and process technology is unique. This is because the individual performance features from the design to the startup of the equipment create a coherent and complete solution from a single source. Our hydraulic presses for metal forming are at home in cold and hot forming. From turbine disks for aircraft to pipeline pipes in the oil and gas industry to longitudinal beams in trucks: In our key industries of automotive, energy, rail and aerospace, we offer the right solution for every product. We supply not only the press, but also the associated process technology. Our range of services includes forging, thick sheet metal forming, raw forming, sheet metal forming and ring rolling. Our special systems for metal forming offer the perfect balance between the use of standard components and a custom-made design.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

A press for all processes Beside the pressing systems for industrial production, Siempelkamp manufactures laboratory press systems – both “try-out” presses for laboratoryscale tests with a starting pressing force of 150 t as well as presses for “fullscale testing”. The laboratory press systems are designed for maximum exibility. With it, all processes of composite production can be investigated. For example, it can be investigated whether press technology is an economic alternative for “autoclave” processes. All processes SMC with glass ber or carbon ber RTM PCM Organo-sheet consolidation Thermoplast forming Hybrid forming Integrated molding and joining of hybrid materials All control methods Force control with position monitoring Position control with force monitoring Each process step can be individually dened and programmed: All relevant process data are recorded and displayed.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Presses for sheet metal forming - Import exportNumber of results

5 ProductsCompany type