- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressed parts

Results for

Pressed parts - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used in printer accessories.

Request for a quote

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

PEKI vertical valve series is made of high quality hot pressed parts and precision turned parts, assembled with modern injection moulded parts and sealing elements made in Germany. Short design with vertical lever arm and float, plastic and stainless steel floats from 3/8 to 1/2″.

Request for a quote

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

PEKI float valve series made of high quality hot pressed parts and precision turned parts, assembled with modern injection moulded parts and sealing elements made in Germany . Compact design with high filling capacity manufactured in brass, chem nickel-plated and stainless steel.

Request for a quote

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

Our PEKI mechanical brass valve series has been manufactured for decades from high-quality hot-pressed parts and precision turned parts, which are assembled with modern plastic injection-molded parts and sealing elements made in Germany. The PEKI is a proven construction which has been tested millions of times. It has been further developed and is now available for the every first time completely in stainless steel / V2A. Many liquids are easily and safely regulated with the PEKI series via its mechanical level control.

Request for a quote

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

Our mechanical PEKI valve series has been manufactured for decades from high-quality hot pressed parts and precision turned parts, which are assembled with modern injection moulded parts and sealing elements from German production. PEKI valves can be manufactured according to customer requirements in construction length, material of the seal as well as in chemical nickel plating.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIMO GROUP GMBH

Germany

The combination of multiple technologies/procedures in one step is called OneShot technology. Semi-finished products (e.g. renewable raw materials such as natural fibers) and decorative materials (e.g. textiles) have to be handled in one production step to finish a component, such as a door panel. FRIMO has developed a modular system that allows for simple and customized configuration of a OneShot plant with all necessary tools. The following units can be integrated into such a plant: feeding station, heating station, calibrating station, material assembly station, press with OneShot tool, part-removal station.

Request for a quote

STRONG MAGNETS GMBH

Germany

Neodymium magnet (aka NdFeB magnet), is the third generation of rare earth magnet, which is composed of Neodymium, Iron, Boron and a few transition metals. With high remanence, high coercive force, high energy product, and high performance /cost, Neodymium magnet is currently the strongest magnet available in the world. Manufacturing Process Neodymium, Iron, Boron and a few transition metals will be mixed into the Neodymium powder, then fine Neodymium powder will be compacted in a die and sintered, fusing the powder in a solid state. There are two ways of pressing die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances. Machining & Tolerance Generally, Neodymium magnet must be machined using diamondgrinding techniques. Sometimes, machining operations may be performed on Neodymium materials with carbide tools, but surface finishes thus obtained may be less than optimal.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

With press capacities between 15 and 500 MN, Siempelkamp's closed-die forging presses oer the optimal solution for numerous application areas. The optimal relationship between press dimension and press force oers our customers maximum benets. Best process and system parameters are the guarantee for high dimensional and repeat accuracy. Siempelkamp supplies hydraulic closed-die forging presses for many dierent application areas. According to the application area, guidance accuracy, cycle time, eccentricity, and speed are optimally adjusted with one another. Depending on the customers' requirement, Siempelkamp's closed-die forging presses are available in dierent designs - as push down and pulldown presses. If desired we can supply these presses as part of a complete solution, from the press segment to the forging plant.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our open-die forging presses play an important part among the forming presses. Siempelkamp supplies complete open-die forging presses equipped with manipulators and ancillary equipment such as lifting turntables and quite a number of additional components. Our presses operate reliably, fast and precisely, operating at pressing forces between 10 and 160 MN. The range of presses available comprise push-down or pull-down designs, two- or fourcolumn designs with oil-hydraulic or water-hydraulic drives. High-stroke frequency contributes to the eciency of these presses. Our customers produce bars, discs, rings, and anges from materials such as steel, high-alloy steel, nickel-based alloys, titanium, and aluminium on these presses. They prefer to order turn-key plants including integrated manipulators, turntable, die magazine, and die-changing system.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The ultra-thin board package consists of a special cylinder conguration with additional double-acting cylinders. Its concept enables the production of ultra-thin engineered boards in a reliable and stable process. A standard ContiRoll® has a degassing zone in its front section. Double-acting cylinders serve to lift the sides of the press gap to enable a controlled degassing. Since ultra-thin boards are produced at especially high speeds, this standard degassing zone is not long enough for the mat to degas. The optional ultra-thin board package includes additional dierential cylinders functioning as double-acting cylinders to extend the degassing zone signicantly. Dierential cylinders in the remaining part of the press ensure that the upper and the lower steel belts do not make contact during ultra-thin board production, even if there were no mat in-between. Features Additional dierential cylinders operating as double-acting cylinders

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

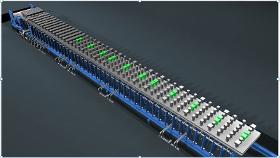

Design and production of press-systems for the rubber industry is one major core competences of Siempelkamp More than 100 years of experience in rubber press lines More than 100 years ago, we put in operation the first conveyor belt press on the market. Only 20 years later, the first large vulcanizing press with a closed frame construction went successfully in operation. Even today, our presses and systems for the rubber industry have unqiue advantages: Durability, speed, high availability and efficiency, which are the most important arguments for our customers to choose a Siempelkamp plant. Proven technology that is trusted in the rubber industry With our broad expertise in the fields of rubber processing industry, we are the world market leader for steel cord and conveyor belt presses. A large part of the conveyor belts used around the world are manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straight-running stability.

Request for a quote

1A STAR TECHNISCHE KUNSTSTOFFE GMBH

Germany

STAR high quality bending film / folding foil is a high quality product, which offers best protection for parts and press brake tools on nearly every press brake machine. It is tested and developed under most difficult conditions. Test our high quality bending film / folding foil / antiscratch film and see, how you can protect your press brake tools, your bended parts and save money by saving time and avoiding extra work! Avoid following problems : Scratches imprints marks other problems caused by the direct contact from press brake tool and part extra work to clean the part after having scratches, imprints or marks scratches on press brake tools

Request for a quote

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

For more than 25 years our name has stood for experience, professional competence and consumer-orientated service. Moreover, our clients hold the opinion that our skills in producing multi-part press tools and fixture constructions are absolutely convincing. These tools are implied for instance within the framework of electronic and automotive industry in favour of processing different materials. Thus, your needs will be developed gradually. By using up-to-date software we produce high standard multi-part press tools for national and international clients. With the professional help of the CAD/CAM-Software (Cimatron) we generate 3D-construcions and solids. For data migration we offer several interfaces: Step – DWG – IGES – DXF – just choose what you need. Immediate interfaces that lead directly from the CAD-workstation to the machine ensure shortest processing times.

Request for a quote

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

Due to our 25 years of experience we are able to produce high-class qualities on favourable terms in the field of tool manufacturing as well. You are looking for the optimal tool, that matches your needs and that keeps your costs low even in the long term? No matter whether we are assigned by automotive, electric or any other sector of industry: we are your tool partners! Let us counsel you individually and you will profit with our nice price-performance ratio soon. Besides multi-part press tools and by using modern CAD-techniques cutting tools we produce deep drawn tools, bending tools and fixture constructions for stamping, bending and drawing parts with a press capacity up to 2800 kN and a sheet thickness of 4.0 mm. Screw threads can be formed non-cuttingly up to M12 during the stamping process. Our tool maker craft tools routinely and professionally that bare a high complexity. Because we can use our experience of long duration in manufacturing precise tools, ...

Request for a quote

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

We accept responsibility for the whole process of production. On the one hand, we set outsourced items or provided parts like Press-in bolts Clinch studs Ball studs Weld screws Weld nuts into complex assembly groups. On the other hand, we offer downstream services like Thread cutting Slide grinding Defatting Special packing operations (in trays / blister packaging, wound on spool, packed in layers) Your needs and wishes always have priority and always will have. For that purpose we cooperate with reliable suppliers, who take charge of downstream surface treatment like: Galvanising Chrome-plating KTL-coating Silver-plating Hardening Press tempering Powder coating On your wish we guarantee particle purity and silicone-free packing.

Request for a quoteResults for

Pressed parts - Import exportNumber of results

16 ProductsCompany type