- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- press machine

Results for

Press machine - Import export

BORNEMANN GMBH

Germany

Machine stamping presses with peg or threaded hole for mounting onto a press. For standard stamping presses we also offer font sizes of 1 to 10 mm with 11 labelling fields on the wheel circumference here. By removing the pin stop, the wheels can be easily rotated, which allows setting the desired combination.

Request for a quote

BORNEMANN GMBH

Germany

Manual stamping presses for steel, tool and machine engineering for simply labelling of multi-digit texts. For standard stamping presses we offer font sizes of 1 to 10 mm with 11 labelling fields on the wheel circumference. By removing the pin stop, the wheels can be easily rotated, which allows setting the desired combination. The striking cap can also be replaced.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites: a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality. Tube measurements up to 60 mm, up to 80 mm and up to 115 mm are covered, depending on the machine. It is also feasible to bend tubes with imperial sizes with the standard tools.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Lesjöfors manufactures deep drawn parts to customers individual requirement in press machines by either progressive tool or transfer tool solutions as well as opportunities for less automated solutions in case of low volume requirement.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

With the battery-operated STAUFF Press Assembly Machine SPR-PRC-H-M, STAUFF provides an ergonomically designed, light-weight and at the same time robust device for the assembly of cutting rings in the Light Series (L) as well as in the Heavy Series (S) according to ISO 8434-1 / DIN 2353 on metric tube ends with outer diameters from 6 mm to 42 mm. The machine has been designed for hand-held, tripod- or table-mounted operation and offers the best technical compromise between maximum flexibility, economic efficiency and a high level of process reliability with considerable reduction of time and cost for the assembly of cutting ring fittings. Short tool change and setup times (with only a few seconds required to manually adjust the assembly pressure) make it possible to carry out the assembly of medium and even small quantities of cutting ring fittings, e.g. during maintenance, servicing, conversion and repair works on hydraulic pipe and tube systems. With the rechargeable battery...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

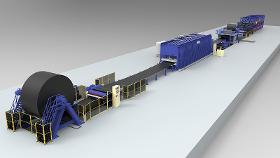

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

One of Siempelkamp’s core competences is the design and manufacture of presses for the rubber industry. With our expertise in this eld we are the world’s number one in steel-cord and conveyor-belt presses with many of the conveyor belts used around the world being manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straightrunning stability. Siempelkamp's excellent manufacturing and high-quality plants are eld proven. Services Single-source supplier Uniform pre-tensioning of the individual steel cables Best pressure distribution in our vulcanising presses Cable clamping and tensioning device with a heavy clamp Compactor lorry with pre-press Pull-roll stand Reeling elements Advantages Excellent thickness tolerances due to multi-cylinder press without requiring press bolsters Safe vulcanizing process for various belt widths by controllable pressure distribution Transparent and controllable production process

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The SMC presses from Siempelkamp are designed in such a way that they can also be used for the RTM process. Short cycle times Since the SMC process is predominantly used in the production of high quantities, apart from precision, a short cycle time plays a important role. And since the compound material is chemically reactive, the time window for achieving an optimum surface quality is also small. The advantages of the Siempelkamp presses: they apply the force extremely quickly to the product, because they close at a very high speed decelerating just before reaching the end position. Depending on the level of automation, the tool change is done automatically – just 120 seconds later the next part can be produced! No stress The precise positioning of the ram plate ensures that the tools are precisely aligned to each other during the complete press stroke – not just on the last millimeters. Under all operating conditions the tools remain parallel.

Request for a quote

SANHA GMBH & CO. KG

Germany

Practical system push fittings with safe and innovative lock function from copper alloys for use in a system with SANHA MultiFit®-Flex and MultiFit®-PEX multi layer plastic tubes for hygienic drinking water and reliable heating installations. Due to their sophisticated construction, SANHA system push fittings offer an especially safe and durable connection and are just as tight as press fittings. The push connection is easy to make and has the distinct advantage that no tools are required. In this way, using 3fit®-Push fittings incurs no cost for buying, repairing or maintenance of press machines. 3fit®-Push system fittings are ideally suited in narrow spaces where it might be difficult to press fittings with jaws or slings such as during the renovation of buildings.

Request for a quote

1A STAR TECHNISCHE KUNSTSTOFFE GMBH

Germany

STAR high quality bending film / folding foil is a high quality product, which offers best protection for parts and press brake tools on nearly every press brake machine. It is tested and developed under most difficult conditions. Test our high quality bending film / folding foil / antiscratch film and see, how you can protect your press brake tools, your bended parts and save money by saving time and avoiding extra work! Avoid following problems : Scratches imprints marks other problems caused by the direct contact from press brake tool and part extra work to clean the part after having scratches, imprints or marks scratches on press brake tools

Request for a quoteResults for

Press machine - Import exportNumber of results

10 ProductsCompany type